Table of Contents

Overview:

Semi hydrogenation is a crucial procedure in chemical synthesis that allows for the controlled hydrogenation of unsaturated molecules. This article explores the field of customized catalysis in semi-hydrogenation, highlighting the importance of selectivity and catalyst design in optimizing chemical reactions.

What is Semi-Hydrogenation?

A chemical process known as semi hydrogenation occurs when a compound receives hydrogen additions, but not all of the available double or triple bonds become saturated. As a result, the compound is partially hydrogenated.

By adding hydrogen to carbon-carbon double bonds, a chemical process known as semi-hydrogenation converts them into single bonds without fully saturating the entire complex. Many chemical compounds, including medicines, polymers, and specialty chemicals, extensively utilize this method in their manufacturing.

The Significance of Tailored Catalysis:

Tailored catalysis is the process of customizing catalyst parameters to improve the efficiency and selectivity of a reaction. In semi hydrogenation, specially designed catalysts are used to bring about chemical changes that are wanted while limiting the production of by-products that are not wanted.

The importance of selectivity in chemical reactions:

The importance of selectivity in semi-hydrogenation lies in its ability to determine the production of particular products with a high degree of purity. The goal of tailored catalysis is to achieve high selectivity by tailoring the interactions between the catalyst and the substrate.

Difficulties encountered during the semi-hydrogenation process:

Finding the best conditions for semi hydrogenation isn’t easy. For example, you have to make sure that the reaction conditions are stable, that the selectivity is optimal for complex substrates, and that the reaction can be repeated and scaled up.

Benefits of Tailored Catalysis:

Tailored catalysis offers several advantages in this hydrogenation, including increased efficacy, reduced waste production, and the ability to customize catalyst characteristics to match specific uses, resulting in more environmentally friendly and sustainable chemical procedures.

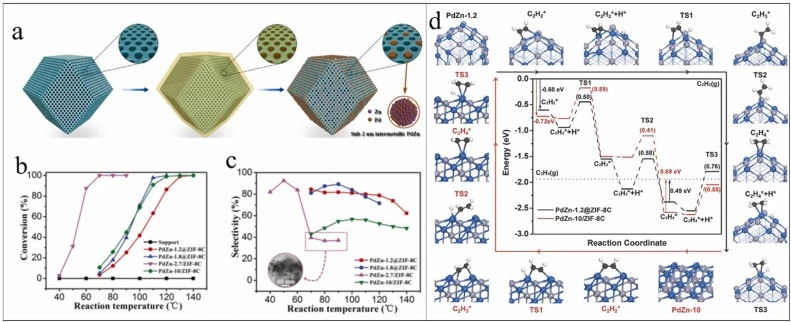

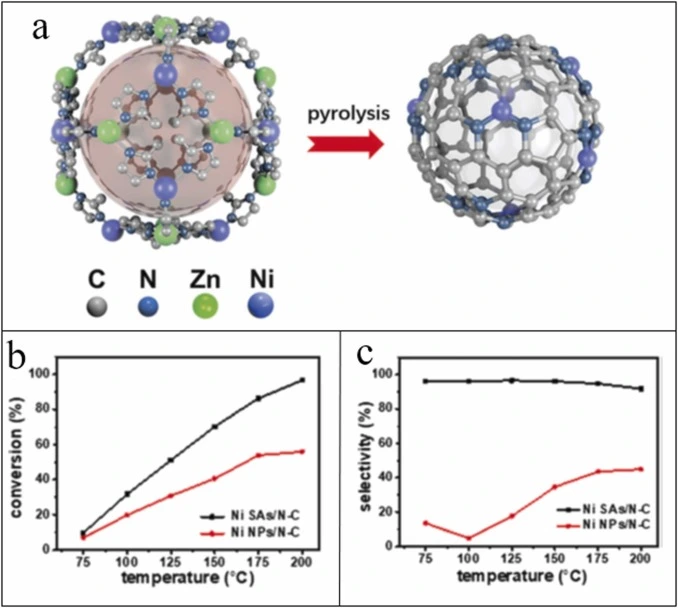

Investigating Catalyst Design:

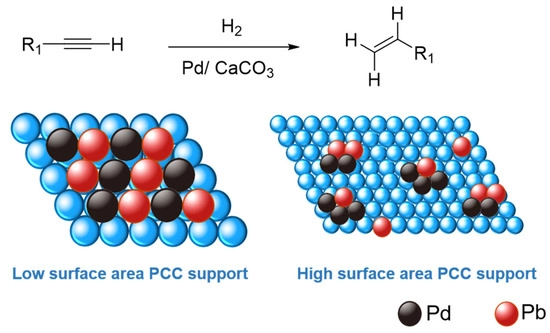

Catalyst design is a complex process that involves tailoring the chemical composition, structure, and surface qualities to control the reaction paths and the selection of products. We design catalysts to selectively interact with various functional groups during the semi-hydrogenation process.

Categories of Catalytic Materials Employed:

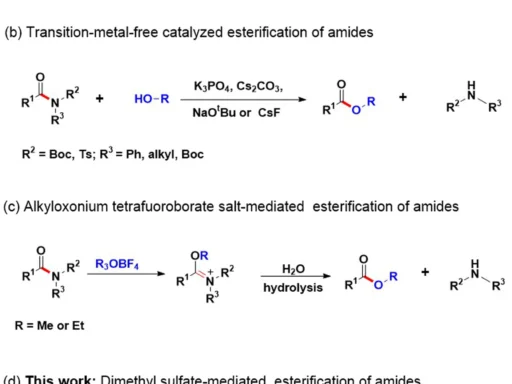

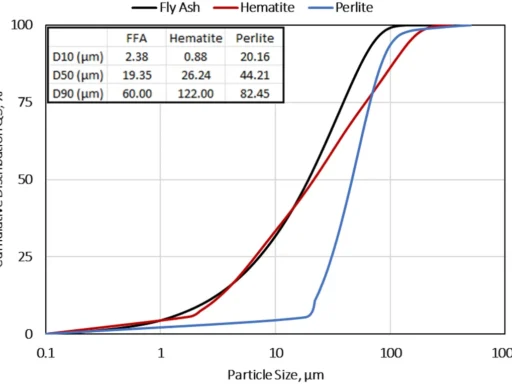

Semi hydrogenation utilizes a range of catalytic materials, such as supported metals like palladium and platinum, metal oxides, and heterogeneous catalysts. We can customize each material’s distinct qualities for specific chemical reactions.

Factors that have a significant impact on catalytic selectivity:

Various parameters, including the catalyst’s structure, the reaction’s temperature and pressure, and the substrate’s composition, determine the catalytic selectivity. Understanding and maximizing these factors is critical for achieving the desired semi-hydrogenation results.

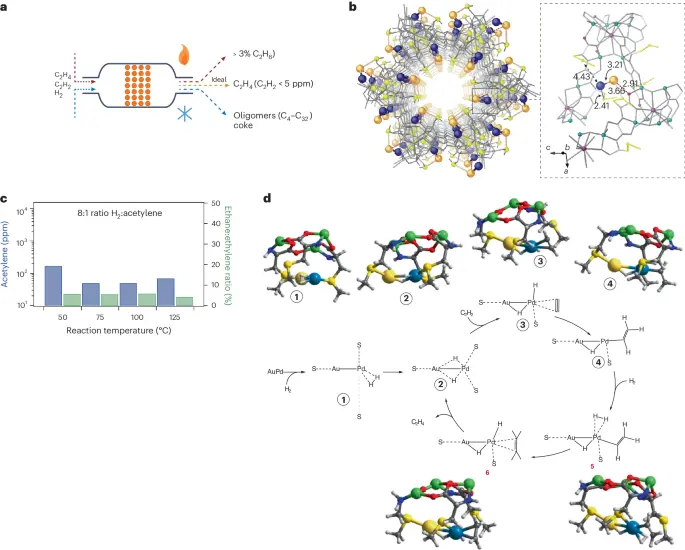

Recent developments in the field of semi-hydrogenation:

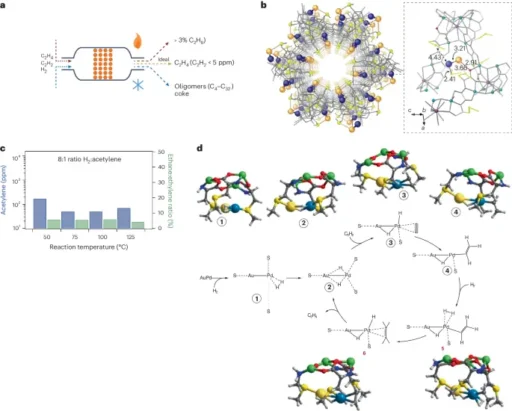

New developments in customized catalysis for this hydrogenation include the creation of new catalyst architectures, advanced methods for characterizing them, and computer-based approaches for developing them. These innovations have significantly improved reaction efficiency and product selectivity.

Utilization of Tailored Catalysis:

Tailored catalysis has a wide range of uses that go beyond semi-hydrogenation. It includes the production of specialty compounds, medicinal intermediates, and renewable fuels. This method enables the synthesis of valuable chemicals with meticulous regulation of reaction paths. Semi Hydrogenation of Phenylacetylene:

Prospects and Advancements for the Future:

The advancement of customized catalysis in semi-hydrogenation depends on the integration of materials research, computational modeling, and process optimization. Current developments include the use of versatile catalysts and continuous-flow systems to improve process scaling and sustainability.

In conclusion:

To summarize, customized catalysis is a revolutionary method for improving semi-hydrogenation processes by providing better selectivity, efficiency, and sustainability. Advancements in research will further propel the use of customized catalysis to foster innovation in chemical synthesis across various sectors.

Frequently Asked Questions About Semi-Hydrogenation and Tailored Catalysis:

1. What advantages does semi-hydrogenation offer in chemical synthesis?

It is possible to change chemical structures very precisely through semi-hydrogenation, which makes it possible to make important intermediate compounds with specific functional groups.

2. What are the distinctions between customized catalysis and traditional catalysis?

Tailored catalysis refers to the process of creating catalysts that have specific features customized for desired reactions, as opposed to classical catalysis, which often employs versatile catalysts with broad applicability.

3. What challenges are associated with achieving a high degree of selectivity in semi-hydrogenation?

It can be hard to get good selectivity in semi-hydrogenation because there are complex substrates and competing reactions. To solve these problems, you need to use complex methods for designing catalysts.

4. How can tailored catalysis contribute to sustainable chemical processes?

Tailored catalysis can significantly enhance the sustainability of chemical processes.

Tailored catalysis helps to advance environmentally friendly and highly efficient chemical processes by reducing waste and optimizing reaction paths.

5. What role does catalyst design play in optimizing semi-hydrogenation reactions?

Catalyst design plays a crucial role in optimizing semi-hydrogenation processes.

The design of a catalyst has a significant impact on the selectivity, stability, and efficiency of a reaction. This allows for the possibility of adjusting reaction conditions and improving product yields.

For more chemistry blogs, visit chemistry Master