Table of Contents

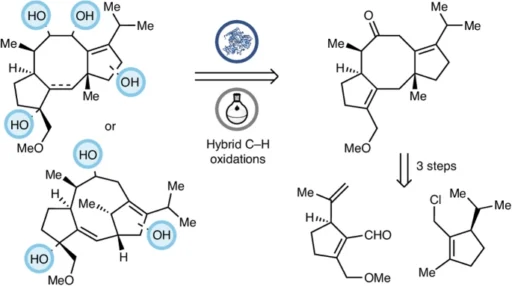

The modular chemoenzymatic synthesis of 10 fusicoccane diterpenoids is a novel and effective method for synthesizing complex natural compounds with various biological functions in organic chemistry. The complexity of this synthetic process, the importance of fusicoccane diterpenoids, and the ramifications for medical and agricultural uses are all examined in this article.

Overview of Modular Chemoenzymatic Synthesis:

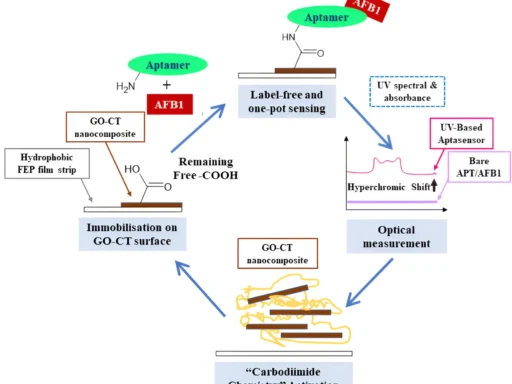

Using a complex technique known as modular chemoenzymatic synthesis, complex compounds can be efficiently and precisely assembled by combining the power of enzymatic transformations with conventional chemical synthesis. As biocatalysts, enzymes are essential to this process because they efficiently and selectively catalyze particular chemical processes.

Gratitude Diterpenoids of Fusicoccane:

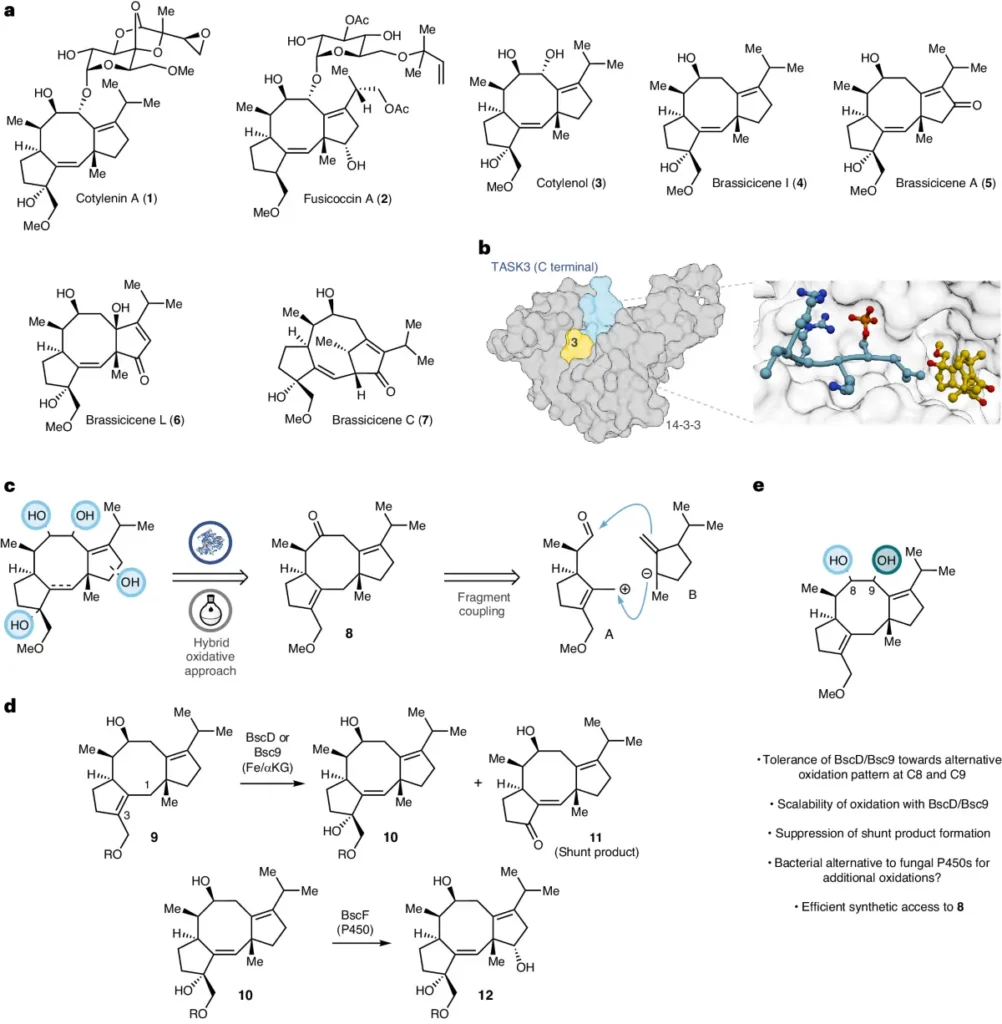

Fusicoccane diterpenoids are a class of natural compounds distinguished by strong biological activities and complex carbon structures. These substances are excellent candidates for therapeutic development and agricultural applications due to their well-known anticancer, antifungal, and anti-inflammatory qualities.

The Synthesis of Fusicoccane Diterpenoids Is Important:

Fusicoccane diterpenoids have intriguing pharmacological properties, which makes their production crucial. Their intricate architectures, however, provide difficulties for conventional chemical synthesis techniques, which frequently lead to low yields and ineffective procedures. Modular chemoenzymatic synthesis presents a promising alternative to effectively access these molecules and overcome these obstacles.

Difficulties with Conventional Synthesis:

Fusicoccane diterpenoids and other complicated natural compounds are frequently synthesized via time-consuming and ineffective multistep chemical processes. Furthermore, it can be challenging to achieve stereochemical control and regioselectivity, which might result in yield and purity that are not ideal.

The function of enzymatic synthesis:

Enzymatic transformations are incorporated into the synthetic route by chemoenzymatic synthesis, which enables exact control over molecule assembly. Because enzymes catalyze particular reactions, complex molecular architectures with high selectivity and efficiency can be formed. This strategy provides more environmentally friendly and sustainable paths to the target molecules, which enhances conventional chemical synthesis techniques.

Important Procedures for Modular Enzymatic Synthesis:

Modular chemoenzymatic synthesis entails the following crucial steps:

1). Enzyme Selection: The process of selecting and optimizing enzymes that can catalyze particular transformations necessary for the manufacture of fusicoccane diterpenoids is known as enzyme selection.

2). Substrate Design: Substrate design is the process of creating and preparing appropriate substrates that can be chemically and enzymatically modified to produce the desired molecules.

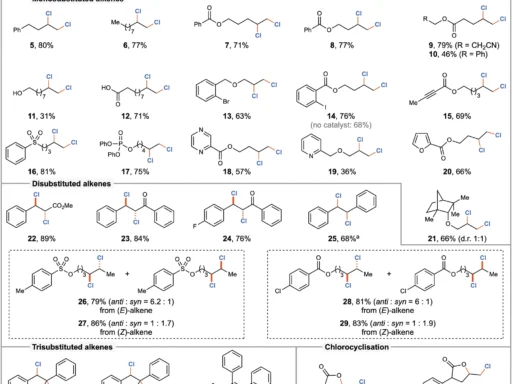

3). Enzymatic Transformations: To put the target compounds’ molecular structure together, enzymes catalyze stereochemical transformations, selective bond forms, and functional group changes.

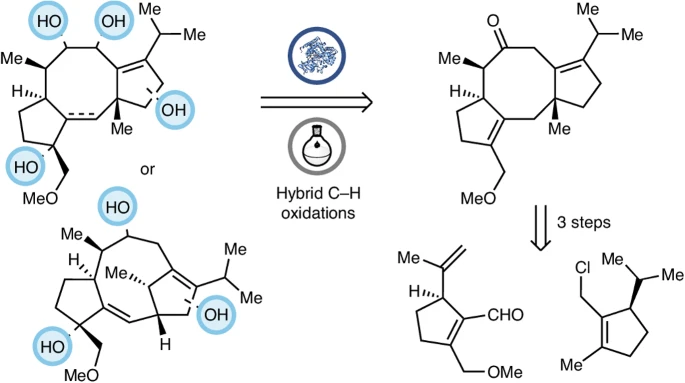

4). Chemical Steps: To further elucidate the molecular structure, chemical processes such as protection-deprotection tactics, functional group manipulations, and cyclizations are utilized.

5). Purification and Characterization: The synthesized compounds are isolated and subjected to spectroscopic and chromatographic tests as part of purification procedures.

Enzymatic Processes in the Synthesis:

Modular chemoenzymatic synthesis uses a variety of enzyme types, such as:

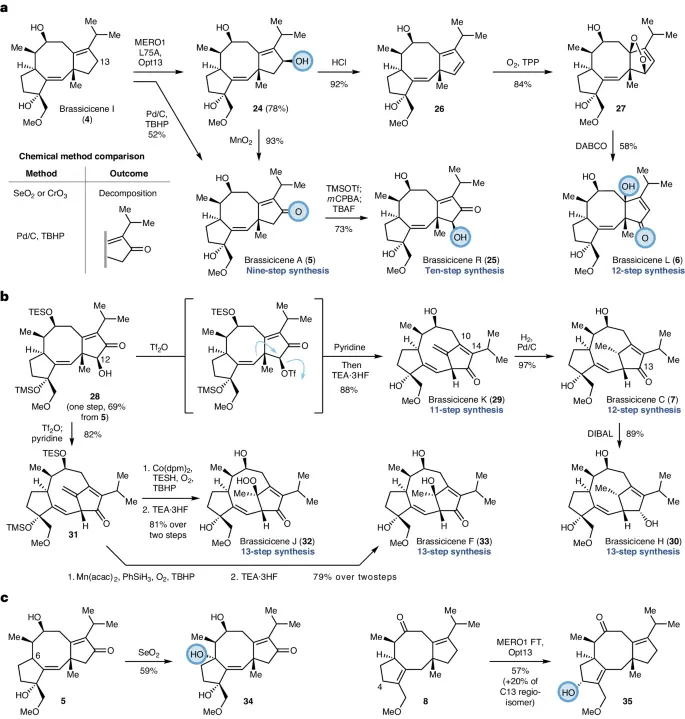

1). Cytochrome P450s: The oxidative reactions that hydroxylation and epoxidation require are catalyzed by cytochrome P450s to change the carbon backbone of diterpenoids.

2). Glycosyltransferases: They improve a molecule’s pharmacokinetic and bioactive qualities by attaching sugar moieties to particular locations on the molecule.

3). Acyltransferases: These enzymes catalyze the transfer of acyl groups, which allows molecules to acquire ester or amide functions.

Chemical Processes in Modular Fabrication:

In synthesis, chemical reactions have a complementary function.

1). Protection-Deprotection Strategies: Reactive functional groups can be temporarily hidden to regulate the regioselectivity of ensuing reactions using protection-deprotection strategies.

2). Manipulations of Functional Groups: The introduction of specific functional groups, such as carbonyl or hydroxyl, to improve chemical or biological reactivity.

3). Cyclization Reactions: These processes create ring structures by forming intramolecular bonds, which are essential for determining the general structure of molecules.

Applications of Diterpenoids from Fusicoccane:

Fusicoccane diterpenoids that are produced have enormous potential in several domains.

1). Pharmaceuticals: investigation of anti-inflammatory, antibacterial, and anticancer effects for potential drug development.

2). Agriculture: By their innate defenses against pests and diseases, they can be used as biopesticides or plant growth regulators.

3). Material science: adding particular functions to materials or polymers.

Prospects for the Future of Enzymatic Synthesis:

Thanks to developments in synthetic techniques and enzyme engineering, the subject of modular chemoenzymatic synthesis is still evolving. Subsequent investigations seek to:

1). To have access to a wider variety of natural items, broaden the scope of the substrate.

2). Create enzyme cascades that are more effective for simplified synthesis routes.

3). Incorporate computer programs for predicting substrates and designing enzymes.

Recent Studies and Advancements:

Novel enzyme-substrate interactions and reaction cascades are being actively studied by researchers to maximize the effectiveness and scalability of modular chemoenzymatic synthesis. Current advancements include the following:

1). Enzyme Engineering: Enzyme engineering is the process of rationally designing or deliberately evolving enzymes to improve their substrate selectivity and catalytic activity.

2). Cascade Reactions: A series of coordinated enzymatic reactions carried out in a single reaction vessel to reduce the number of purification steps and waste production.

3). Bioprocess Engineering: Integrating chemoenzymatic synthesis into scalable bioreactor systems for industrial production is known as bioprocess engineering.

Environmental Consequences:

Compared to conventional chemical synthesis techniques, modular chemoenzymatic synthesis has the following advantages for the environment:

1). Decreased Waste: Because enzyme reactions are so selective, fewer undesirable byproducts are produced.

2). Greener Chemistry: By using biocatalysts, less dangerous chemicals and solvents are used.

3). Sustainable Production: Complying with sustainable manufacturing principles, bio-based and renewable feedstocks are accessible for synthesis.

In summary:

To sum up, modular chemoenzymatic synthesis is a revolutionary method for obtaining complicated natural compounds such as fusicoccane diterpenoids. This technique enables the efficient and sustainable synthesis of bioactive molecules with a wide range of applications in materials science, agriculture, and medicine by utilizing the synergistic properties of enzymes and chemical synthesis.

Frequently Asked Questions:

1). Fusicoccane diterpenoids: what are they?

A class of naturally occurring chemicals known as fusicoccane diterpenoids is distinguished by their intricate carbon skeletons and strong biological activity, such as antibacterial and anticancer capabilities.

2). What distinguishes conventional chemical synthesis from chemoenzymatic synthesis?

Chemoenzymatic synthesis is a technique that combines chemical reactions and enzymatic transformations to precisely control stereochemical results and molecule assembly.

3). What benefits can modular chemoenzymatic synthesis offer?

This methodology is a very selective, efficient, and sustainable approach, rendering it perfect for obtaining intricate natural compounds possessing medicinal properties.

4). How may drug discovery be affected by modular chemoenzymatic synthesis?

Through the efficient synthesis of bioactive molecules, this technique expedites the search for new therapeutic agents and potential medication candidates.

5). What avenues will chemoenzymatic synthesis research pursue in the future?

Future studies seek to improve reaction conditions, add more enzymes to the toolkit, and use computational techniques for predictive synthesis design.

For more chemistry blogs, visit chemistry Master