Table of Contents

Overview of Aflatoxins:

Exposure to aflatoxins can lead to a serious and frequently fatal condition known as aflatoxicosis. It continues to be a significant problem for global public health and food safety. Specific types of fungi like Aspergillus flavus and Aspergillus parasiticus generate these harmful substances, which often pollute agricultural produce and pose a substantial risk to both human and animal well-being. Ensuring the identification and control of aflatoxin contamination is crucial to prevent the occurrence of aflatoxins epidemic.

Forensic tools are essential for detecting and analyzing aflatoxins, as they enable the identification and mitigation of sources of contamination. Conventional laboratory techniques, although efficient, frequently lack in terms of rapidity, expense, and suitability for on-site testing. In the field of forensic research, the development of sophisticated sensing technologies, specifically aptasensors activated by ultraviolet light and made from fluorinated ethylene propylene (FEP) strips, is a revolutionary method. These cutting-edge sensors provide a portable, fast, and extremely sensitive approach to detecting aflatoxins, making them a crucial tool in the ongoing battle against aflatoxins.

Comprehending Aflatoxins:

Ingestion of aflatoxins, secondary metabolites produced by Aspergillus species, results in aflatoxins. The poisons possess a high level of potency and are carcinogenic, resulting in a range of health problems, including liver damage, immune system suppression, and, in extreme circumstances, fatality. Aflatoxins primarily originate from tainted crops such as maize, peanuts, and tree nuts, which are essential food supplies in numerous places, especially in poor nations.

Environmental factors such as temperature, humidity, and storage conditions greatly affect the growth of Aspergillus molds and the formation of aflatoxins. Inefficient agricultural methods and insufficient storage infrastructure raise the likelihood of contamination. Gaining insight into these influential aspects is crucial for formulating efficient measures to prevent and manage the situation.

Conventional detection techniques:

Traditionally, the detection of aflatoxins has been dependent on laboratory methods such as high-performance liquid chromatography (HPLC) and enzyme-linked immunosorbent assays (ELISA). HPLC, or High-Performance Liquid Chromatography, is a very effective analytical technique used to separate, identify, and measure the quantities of different chemicals present in a given sample. ELISA, in contrast, employs antibodies to identify certain antigens, providing excellent sensitivity and specificity.

Although these procedures are effective, they have significant limits. These tests necessitate advanced technology, skilled staff, and a significant amount of time to carry out, which makes them less appropriate for immediate, on-site testing. Furthermore, the costs associated with these methods can be prohibitive, especially in low-resource settings. Regulatory regulations require rigorous testing procedures to ensure food safety, but there is still a lack of accessible and speedy detection methods.

Progress in the field of forensic science:

Forensic science has made notable progress, especially due to the emergence of biosensors and aptasensors. Aptasensors are a state-of-the-art method for detecting toxins. They make use of aptamers, which are synthesized oligonucleotides that have a strong affinity for specific target molecules. These sensors integrate the accuracy of molecular recognition with the convenience of on-site testing, providing a feasible solution to the difficulties presented by conventional approaches.

Aptamer technology is based on the capacity of aptamers to adopt distinct three-dimensional structures that specifically attach to target molecules. The act of binding produces a detectable signal that can be measured to determine the presence and amount of the desired substance. Aptasensors have significantly transformed the process of on-site detection by offering a portable, fast, and precise method for identifying pollutants in different situations.

UV light can activate aptasensors:

Ultraviolet excitable aptasensors utilize the characteristics of ultraviolet light to stimulate fluorophores present in the sensor. Aflatoxin binding to the aptamer triggers a fluorescence shift, allowing for monitoring and quantification. This technique provides numerous benefits, including exceptional specificity and sensitivity, enabling the identification of even minuscule quantities of aflatoxins.

These sensors function by combining aptamers with fluorescent molecules that produce light when stimulated by ultraviolet radiation. The interaction between the aptamer and the aflatoxin modifies the fluorescent signal, allowing for a direct assessment of the toxin’s existence. Comparative evaluations have demonstrated that ultraviolet excitable aptasensors surpass most conventional detection methods in terms of velocity, precision, and user-friendliness.

Fluorinated ethylene propylene makes up FEP strips:

For excitable UV aptasensors, FEP strips are essential. Fluorinated ethylene propylene (FEP), a specific kind of fluoropolymer, is renowned for its exceptional resistance to chemicals, minimal friction, and remarkable transparency to ultraviolet radiation. The aforementioned qualities render FEP an optimal substance for fabricating resilient and efficient sensor strips.

One cannot overstate the significance of FEP in apt sensory performance. The sensor’s chemical resistance ensures its stability and functionality under various climatic conditions, while its transparency facilitates effective UV light transmission, thereby improving the sensor’s sensitivity. Furthermore, FEP’s reduced friction allows for easy manipulation and use of the sensor strips.

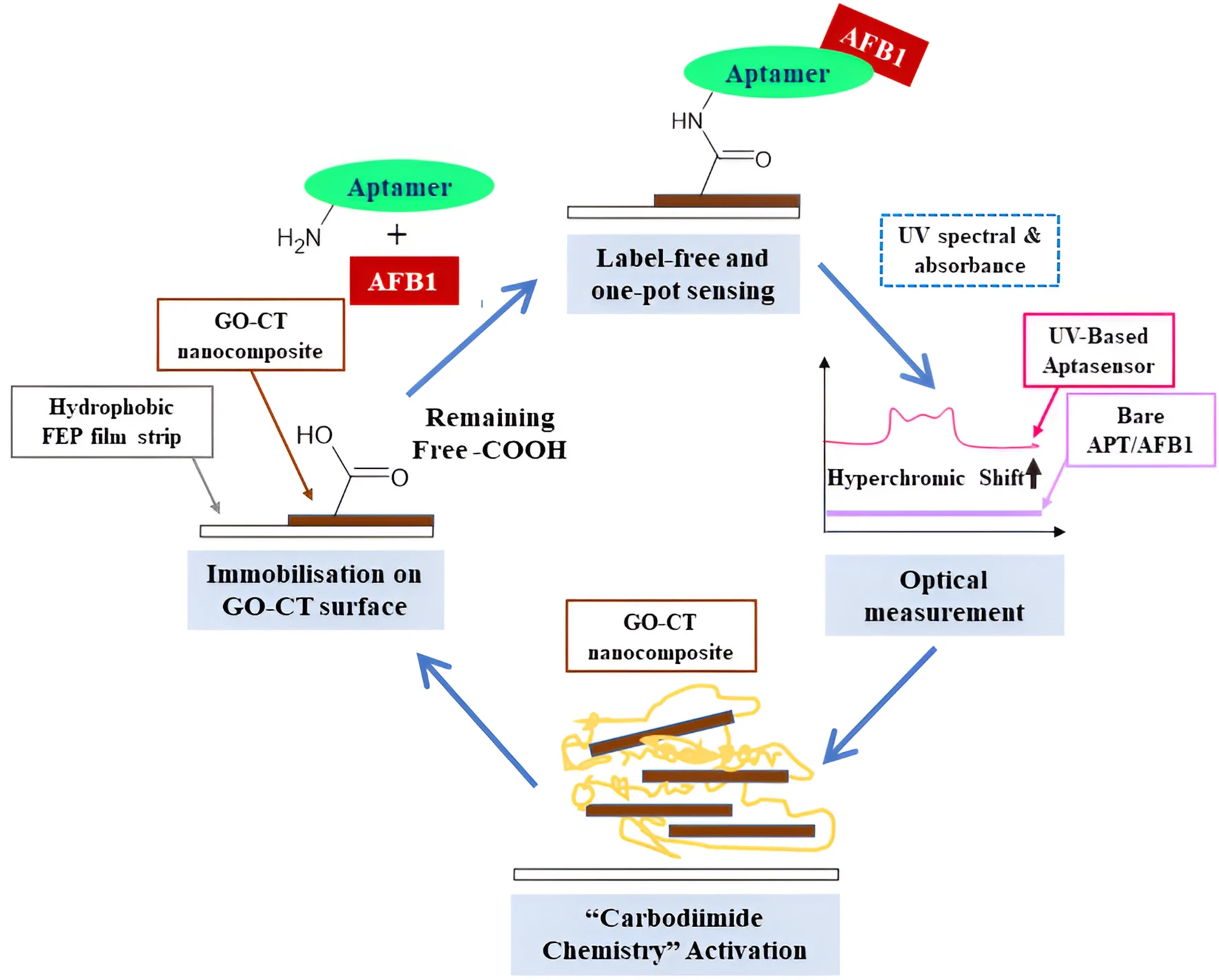

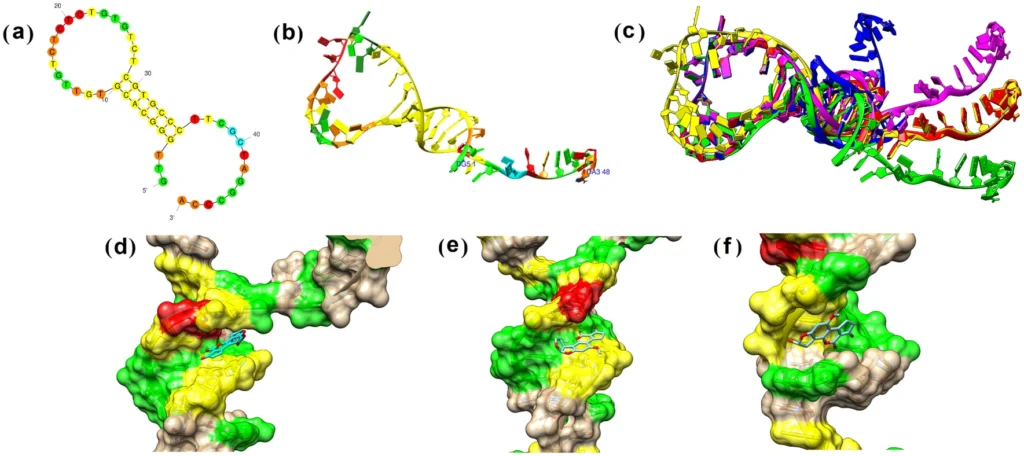

Aptamer structure modeling and molecular docking results. (a) Mfold model. (b) 3D structure from 3dRNA v2.0 web server. (c) Overlapping structure of the 5 predicted aptamer models (refer to Table 1). (d) Top binding pose for binding site 1 (Aptamer3_1). (e) Top binding pose for binding site 2 (Aptamer5_1). (f) Top binding pose for binding site 3 (Aptamer1_1).

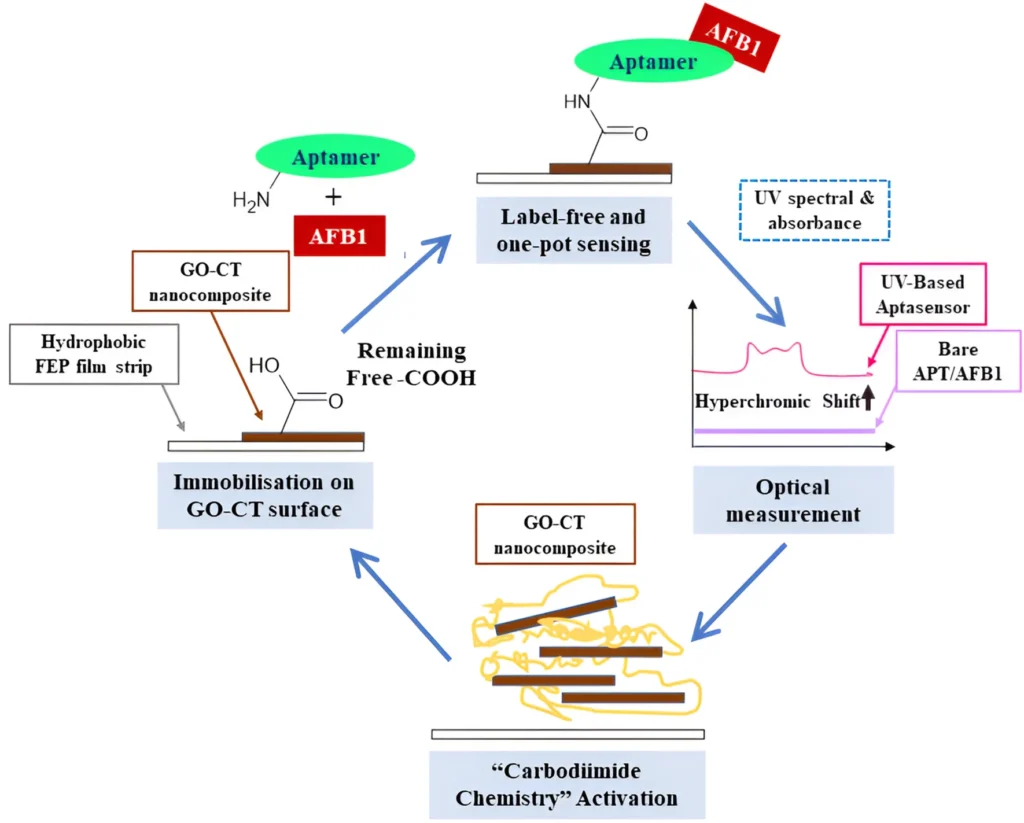

Creation of the Ultraviolet Excitable Aptasensor:

The process of making UV excitable aptasensors consists of numerous critical stages, beginning with the sensor’s conception and construction. The method begins by carefully choosing and combining particular aptamers that specifically target aflatoxins. Next, we fix the aptamers onto the FEP strip, creating a durable and sensitive sensor surface.

Technical standards and calibration are essential for guaranteeing the sensor’s precision and dependability. This entails optimizing the concentration of aptamers on the strip and refining the fluorescence detection settings. In addition, the fabrication process involves thorough testing to verify the sensor’s performance and develop standardized operating methods.

The aptasensor’s functionality:

The UV excitable aptasensor’s operation relies on a simple yet very efficient detection technique. We apply a suspected aflatoxin sample to the sensor using the FEP strip. Aflatoxins initiate a binding interaction with the aptamers, resulting in a fluorescence alteration.

UV radiation quantifies the fluorescence alteration, and we analyze the acquired data to determine the concentration of aflatoxins in the specimen. The sensor’s exceptional specificity guarantees the detection of only aflatoxins, thereby minimizing the possibility of false-positive results. The entire process is expeditious, generally producing outcomes within minutes, making it perfect for on-site testing.

Field Applications:

UV light-activated aptasensors hold great promise for use in numerous fields. Farmers can promptly intervene and prevent the spread of poisons by using these sensors in agriculture to monitor crops for aflatoxin contamination. Sensors in food processing facilities play a crucial role in guaranteeing product safety by offering prompt and dependable testing at every stage of production.

These sensors are extremely advantageous in forensic investigations. These sensors can trace the source of aflatoxin contamination, aiding in the identification of responsible parties and the implementation of corrective measures. Case studies have shown that UV excitable aptasensors are highly useful in various real-world situations, showcasing their versatility and efficiency.

These sensors’ versatility in a variety of situations increases their usefulness. Whether used in a controlled laboratory environment or out in the field, the sensors consistently deliver precise and reliable results, making them a versatile instrument for detecting aflatoxins in different situations.

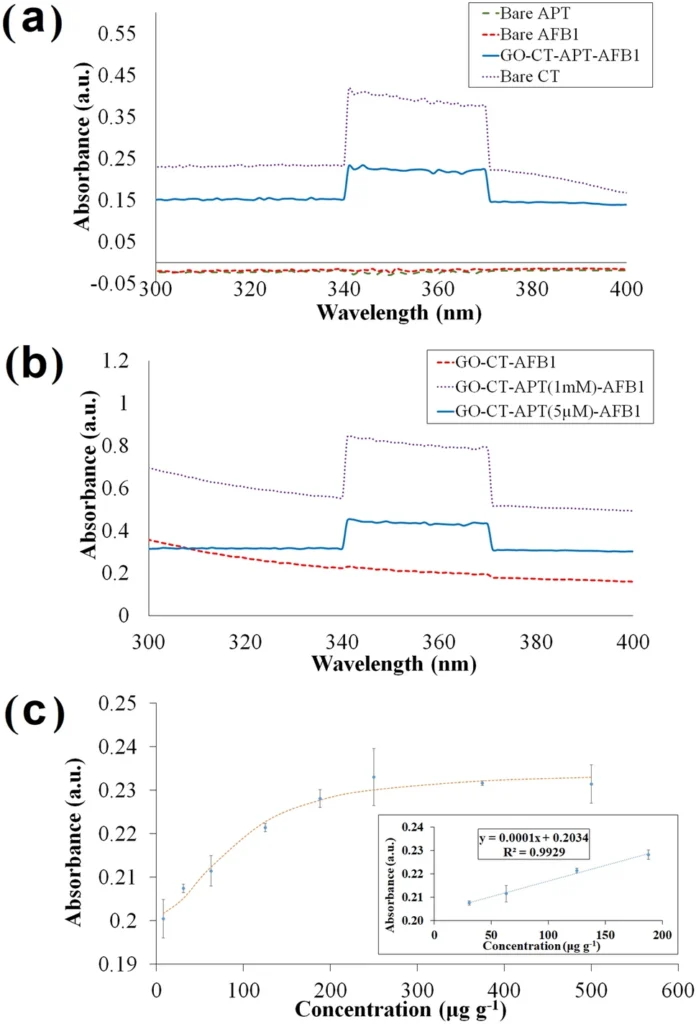

Selectivity and sensitivity profiles of UV-based sensor. (a) The selectivity spectral of bare materials and aptamer-functionalized conducting graphene oxide-chitosan with π–π stacked AFB1. (b) The UV spectral of AFB1 aptasensor in 1 mM versus 5 µM aptamer concentration. (c) A sigmoidal response curve of the optical aptasensor towards AFB1 concentration detection between 8 and 500 μg g−1. The inset shows a linear range profile from 71.8 to 188 µg g−1 with 23.7 μg g−1 detection limit AFB1.

Benefits of the Ultraviolet Excitable Aptasensor:

A key benefit of UV-excitable aptasensors is their mobility. Unlike conventional laboratory-based approaches, these sensors allow for convenient on-site transportation and use, eliminating the need for substantial infrastructure. The ability to easily transport this technology is especially advantageous in environments with limited resources, where there may be restrictions on accessing sophisticated laboratory equipment.

The sensors exhibit remarkable speed and precision. By offering prompt outcomes in a matter of minutes, they facilitate swift decision-making and instant action to tackle contamination. In contrast to conventional approaches, which may require several hours or even days to produce outcomes, The sensors’ excellent sensitivity guarantees the detection of even trace amounts of aflatoxins, hence boosting their efficacy.

Another notable benefit is its cost-effectiveness. The sensors’ low production and utilization costs make them readily available for extensive use, particularly in underdeveloped countries where aflatoxin contamination is a significant concern. Their cost-effectiveness, coupled with their user-friendly nature, renders them an appealing choice for a wide range of individuals involved in agriculture, including farmers and food safety inspectors.

Obstacles and Constraints:

Although UV excitable aptasensors have many benefits, they also face specific challenges and constraints. Long-term sensor stability is an inherent concern. Maintaining the functionality and accuracy of the sensors over long periods is essential for their reliability. To tackle this issue, continuous research and development efforts are necessary to improve the resilience of the sensors.

Calibration and standardization are critical considerations. Establishing standard operating procedures can maintain consistency and ensure accurate measurements from the sensors. Creating reliable calibration standards is crucial for the general acceptance of these sensors.

The intricate sample matrices cause an additional obstacle in the form of interference. Real-world samples may contain diverse chemicals that can impact the sensor’s performance. To address this interference, it is necessary to meticulously design and optimize the sensors to ensure their specific detection of aflatoxins while minimizing the influence of other components.

Prospects for the future:

The prospects for the future of UV excitable aptasensors appear excellent, with numerous intriguing possibilities on the horizon. Researchers are currently focusing on enhancing the performance of these sensors, specifically focusing on increasing their sensitivity and specificity. We anticipate additional innovations driven by advancements in technologies like multiplexing, which enables the simultaneous detection of many poisons.

The potential for combining aptasensors with other forensic technology is equally significant. By integrating these sensors with additional technologies, it is possible to create a full solution for the detection and management of aflatoxin contamination. This integration has the potential to improve the overall efficacy and efficiency of forensic investigations.

Another promising possibility is to broaden the range of uses for excitable ultraviolet aptasensors beyond just detecting aflatoxin. Aptamer technology can identify a diverse array of pollutants, including additional mycotoxins, pesticides, and infections. The flexibility of these sensors allows for their application in a wide range of sectors, including environmental monitoring and public health.

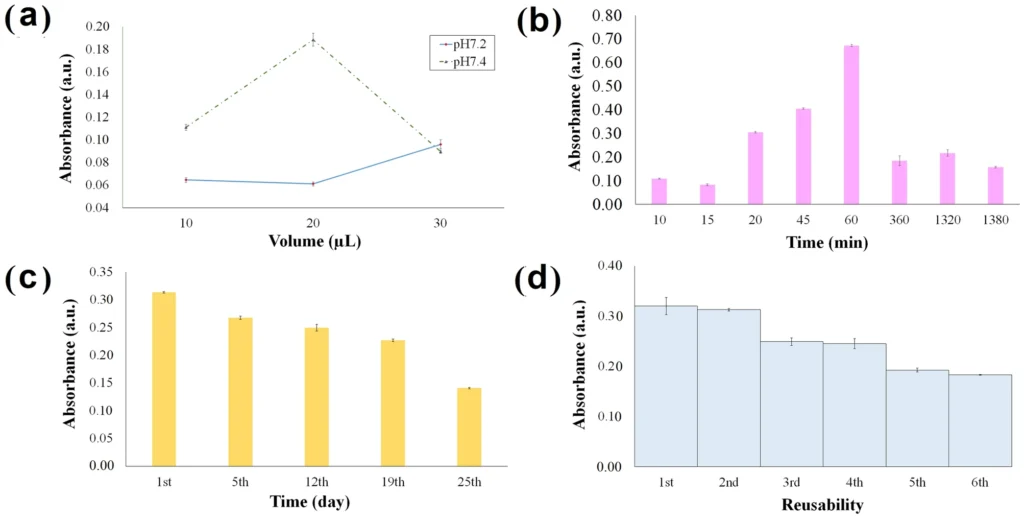

Optimal working conditions based on optical behaviour of AFB1-sensing aptasensor. (a) The response plots of EDC-NHS efficiency assessment with differing pH and loading volume. (b) The response time trend for the one-pot incubation between EDC, NHS, aptamer, and AFB1 on the GO-CT surface. (c) The solid-state aptasensor stability is maintained throughout 25 days of storage at room temperature. (d) The reversibility profile after consecutive loadings of non-modified aptamer on aptasensor was fabricated with a readily immobilized AFB1-targeted aptamer.

Impact on Forensic Science:

The use of ultraviolet-responsive aptasensors has the potential to revolutionize forensic research. These sensors improve the investigative process by offering a fast, dependable, and on-site detection approach for aflatoxins. This allows for quicker responses to contamination incidents. This has the potential to result in more efficient interventions and enhanced public health outcomes.

The broader implications for food safety and security are also noteworthy. It is imperative to prioritize the security of the food supply chain to effectively avoid outbreaks of aflatoxicosis and safeguard consumers. Using sophisticated sensing technologies, such as ultraviolet excitable aptasensors, can be critical in achieving this goal.

Effective collaboration in research and development is crucial for fully harnessing the capabilities of these sensors. Collaborations among academic institutions, industrial players, and regulatory agencies can stimulate innovation and expedite the implementation of novel technology. By collaborating, these organizations can create and execute efficient strategies for detecting and controlling aflatoxin contamination.

In conclusion:

Overall, the development of aptasensors using fluorinated ethylene propylene (FEP) strips stimulated by ultraviolet light represents significant advancements in the diagnosis of aflatoxicosis. These sensors provide a promising forensic instrument that effectively addresses the issues presented by aflatoxin contamination by combining portability, speed, and precision. We expect the influence of these sensors on food safety and forensic science to increase as scientific research and novel technologies develop, ushering in a new era in the fight against aflatoxins.

The advancement of forensic detection technologies is a clear demonstration of the efficacy of scientific innovation. By adopting innovative technology and methodologies, we can improve our capacity to identify and control pollutants, thereby protecting public health and guaranteeing the safety of our food system. The development and use of sophisticated sensing technologies, such as ultraviolet excitable aptasensors, are critical in the ongoing attempt to detect aflatoxin.

Frequently Asked Questions:

1). Aflatoxins are toxic compounds produced by certain types of fungi that can contaminate food and feed products.

Aflatoxins are poisonous byproducts generated by some fungi, specifically Aspergillus flavus and Aspergillus parasiticus. These poisons possess strong carcinogenic properties and can lead to severe health complications, such as liver damage and immune system suppression. They frequently pollute crops such as maize, peanuts, and tree nuts.

2). What is the mechanism by which the ultraviolet-responsive aptasensor functions?

The aptasensor, which is sensitive to ultraviolet light, uses ultraviolet radiation to stimulate the fluorophores present in the sensor. The binding of aflatoxins to the aptamer induces a fluorescence change, enabling the detection and quantification of aflatoxins in a sample. This approach provides a high level of specificity and sensitivity.

3). What’s the purpose of using FEP in these sensors?

The sensors utilize fluorinated ethylene propylene (FEP) due to its exceptional chemical resistance, minimal friction, and outstanding ultraviolet light transparency. FEP possesses qualities that make it an ideal material for producing robust and efficient sensor strips capable of reliable operation under a variety of environmental conditions.

4). What are the benefits of on-site detection?

On-site detection offers numerous advantages, such as the ability to quickly and effortlessly examine materials without the need for elaborate laboratory equipment. This enables prompt decision-making and instant action to tackle contamination. Furthermore, the portability and cost-efficiency of on-site sensors make them easily available for extensive use, especially in areas with limited resources.

5). What are the potential limitations or disadvantages of this technology?

Ultraviolet excitable aptasensors may have several limitations, such as the sensor’s stability over time, the need for accurate calibration, and the potential for interference from other compounds in complicated samples. Ongoing research and development are essential to tackle these problems and enhance the dependability and efficacy of the technology.

6). What is the comparative analysis between this technology and older methods?

Ultraviolet excitable aptasensors provide various advantages over classic technologies like HPLC and ELISA, including portability, rapidity, and cost-effectiveness. Aptasensors offer a more practical solution for instant testing and decision-making compared to traditional approaches, as they may provide speedy results on-site without the need for sophisticated equipment or experienced personnel.

7). What are the legal consequences of using such sensors?

Utilizing excitable UV aptasensors can help meet regulatory requirements for aflatoxin detection by delivering precise and prompt results. These sensors can ensure adherence to food safety requirements and streamline the application of quality control measures in agricultural and food processing environments.

8). What are the potential applications for these sensors in poor countries?

Ultraviolet excitable aptasensors offer a cost-effective and feasible alternative to on-site testing in developing countries, where aflatoxin contamination is a significant issue. Due to their portability and user-friendly nature, these devices are readily available to farmers and food safety inspectors, aiding in the prevention of aflatoxicosis epidemics and safeguarding public health.

9). What are the expected future advancements in this field?

Potential advancements in this area include improving the accuracy and selectivity of aptasensors, creating the ability to detect numerous toxins at the same time, and combining these sensors with other forensic technology. We anticipate that ongoing innovation and study will propel further breakthroughs and broader uses of aptasensors.

10). What is this technology’s global impact on the food industry?

Utilizing UV excitable aptasensors in the worldwide food business can greatly improve food safety by offering a dependable and effective approach for identifying aflatoxins. These sensors can help prevent contamination, guarantee product quality, and protect consumers, ultimately improving the food supply chain’s safety and security.

For more chemistry blogs, visit chemistry Master