Table of Contents

Overview of Carbonate Decarbonization:

Decarbonization has emerged as a crucial global objective in response to the perils of climate change. Industrial sectors worldwide are investigating cutting-edge technology to mitigate carbon emissions and contribute to achieving global climate objectives. One of the most promising technologies is molten carbonate decarbonization, which captures carbon while simultaneously producing power. Nevertheless, groundbreaking advancements are required for this approach to fully achieve its maximum capabilities, especially in the materials employed in these systems. An example of such innovation is the creation of a novel electrolyte that has the potential to transform the process of molten carbonate decarbonization completely. Large-scale C2CNT electrolysis.

Electrolytes for Decarbonization: A Critical Analysis:

Electrolytes are essential components in numerous electrochemical reactions. Their importance in decarbonization lies in their ability to promote the movement of ions across electrodes, allowing for the steady and effective collection of carbon dioxide (CO2). In the absence of an appropriate electrolyte, the decarbonization process may encounter inefficiencies, therefore reducing its feasibility for extensive industrial application.

In the context of molten carbonate decarbonization, the significance of electrolytes is more pronounced. The elevated temperatures required for this procedure, typically above 600 °C, necessitate an electrolyte that not only exhibits efficient electrical conductivity but also maintains stability below these harsh settings. Historically, conventional electrolytes have had challenges in this regard, resulting in problems such as limited operating longevity and significant environmental degradation.

The Definition of molten carbonate decarbonization:

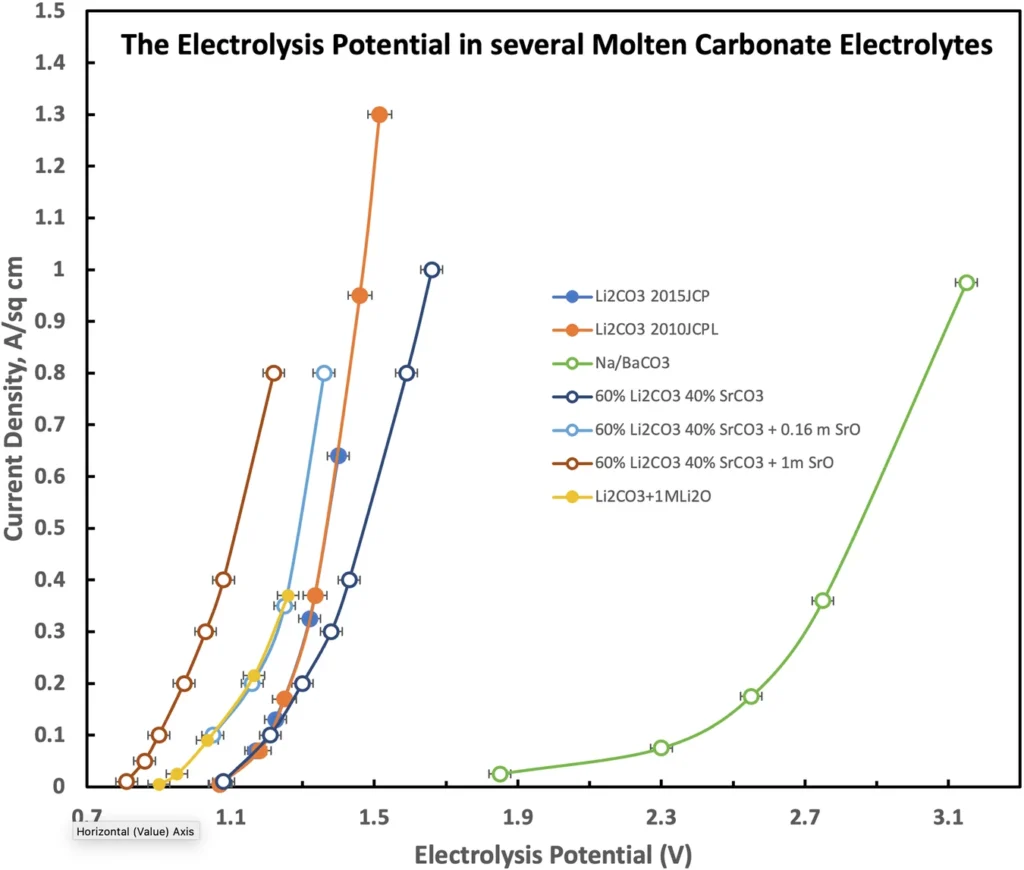

Molten carbonate electrochemical cells (MCEC) are of paramount importance in the process of molten carbonate decarbonization. These cells function by utilizing a liquefied carbonate electrolyte to sequester carbon dioxide from industrial exhaust emissions. The electrolyte catalyzes the electrochemical reaction that transforms CO2 into a more readily sequestered form, typically generating power as a secondary result. These characteristics render it a compelling technology for industries that are significant contributors to carbon emissions, such as power plants and manufacturing sites. Carbonate electrolysis potential was measured in several molten carbonates.

Current Limitations of Molten Carbonate Decarbonisation:

Although it has great potential, the process of molten carbonate decarbonization encounters various obstacles. One of the primary concerns is the efficacy of existing systems. The current electrolytes employed in MCEC frequently undergo rapid degradation at elevated temperatures, therefore diminishing their long-term efficacy. Furthermore, the amount of energy required to maintain the electrolyte’s liquefied condition can limit the total energy efficiency of the given procedure.

Stability is an additional matter of concern. A significant number of conventional electrolytes exhibit thermal instability, resulting in degradation when exposed to the elevated temperatures necessary for the decarbonization of molten carbonate. The aforementioned circumstances result in frequent substitutions, and increased operational expenses, and eventually restrict the potential for expansion of this technology. Additionally, some traditional electrolytes can pose environmental risks during manufacturing and use.

The Innovation: A Novel Electrolyte for Systems Utilizing Molten Carbonate

Introducing the novel electrolyte—a revolutionary advancement specifically developed to overcome the constraints of conventional materials employed in molten carbonate decarbonization technology. The composition of this electrolyte exhibits a distinctive combination of chemicals that effectively augment its stability, conductivity, and environmental performance. The Genesis Device® kiln is used for large-scale CO2 molten carbonate electrolysis.

Enhanced electrical conductivity and increased efficiency:

One outstanding feature of this novel electrolyte is its significantly improved conductivity performance. This electrolyte effectively reduces the energy needed for decarbonization by enhancing ion mobility between electrodes. Indeed, research has demonstrated that the novel formulation has the potential to enhance the overall efficiency of the system by up to 30%, rendering molten carbonate decarbonization a significantly more energy-efficient operation.

Enhanced stability and durability:

Moreover, its stability is another significant advantage. Unlike conventional electrolytes that deteriorate with time, this novel substance has been specifically designed to endure the high temperatures that are inherent in the process of molten carbonate decarbonization. For firms implementing this technology, this translates to fewer frequent replacements, decreased downtime, and eventually reduced operational expenses.

The Novel Electrolyte’s Key Environmental Advantages:

From an environmental perspective, the new electrolyte signifies a substantial advancement. In addition to its contribution to reduced CO2 emissions via more effective decarbonization, its manufacturing process also results in a smaller carbon footprint. The formulation of this product incorporates more sustainable elements, and its extended operational lifespan effectively minimizes waste.

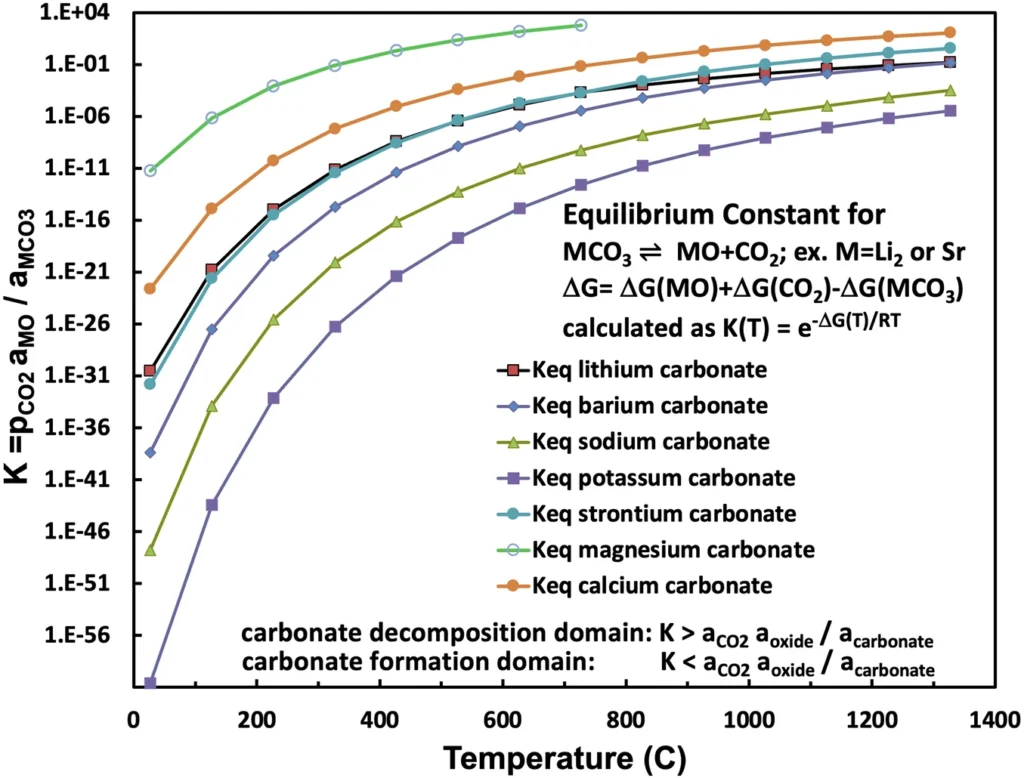

Through its promotion of a cleaner and more effective decarbonization process, this novel electrolyte is assisting the industry in making significant progress toward achieving global emission reduction goals. Equilibrium constant for CO2 release for a range of alkali and alkali earth carbonates.

Analysis of the Novel Electrolyte’s Potential Applications:

The novel electrolyte has extensive applicability in several segments of the industry. The capacity of this technology to enhance efficiency and longevity renders it a compelling choice for power production, especially in coal and natural gas facilities seeking to mitigate their carbon emissions. Furthermore, it can make a vital contribution to the incorporation of renewable energy by capturing CO2 during periods of high production, therefore compensating for the intermittent nature of sources like solar and wind.

Application in Electricity Generation:

Molten carbonate decarbonization has the potential to revolutionize technology in conventional power generation facilities. By implementing this novel electrolyte, generating facilities could decrease emissions without compromising or potentially enhancing energy production. This practice not only contributes to environmental preservation but also provides a financially efficient resolution for energy corporations facing the imperative to decrease their carbon emissions.

Applications in Heavy Industry:

The steel and cement manufacturing sectors are major sources of worldwide CO2 emissions. This novel electrolyte’s implementation has the potential to significantly reduce emissions in these industries by facilitating the most effective carbon capture methods, resulting in cost savings on carbon credits and regulatory penalties.

Obstacles in Implementing the Novel Electrolyte:

Despite its potential, implementing this novel electrolyte is not without obstacles. A major obstacle is the cost, as the development and production of the new material necessitate financial commitment, and there may be challenges in obtaining certain raw ingredients. Furthermore, the process of modifying the current infrastructure to suit the new electrolyte could incur significant expenses and take a considerable amount of time.

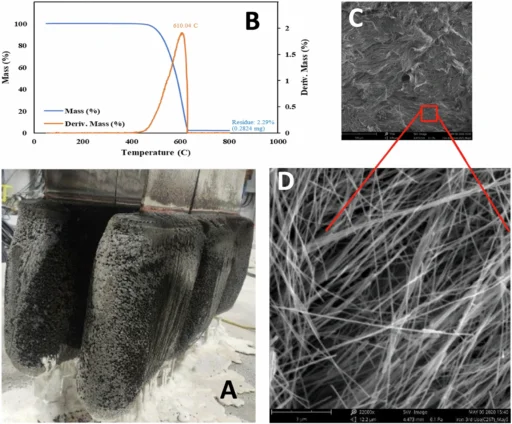

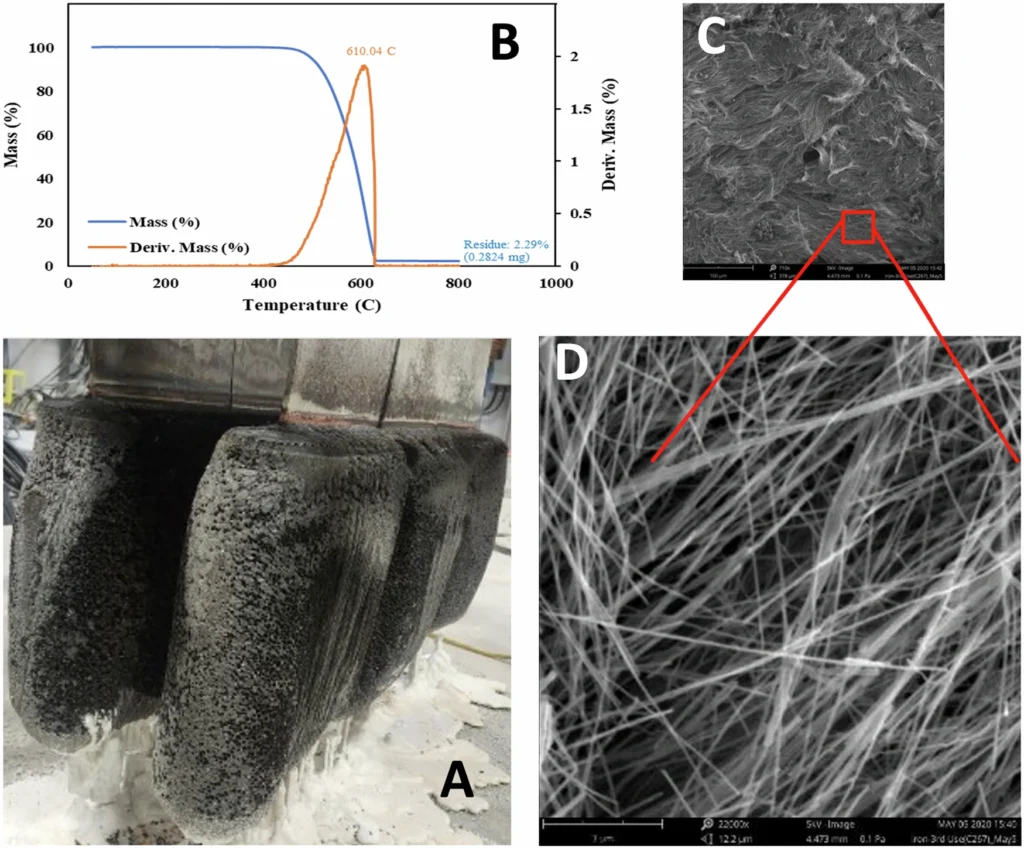

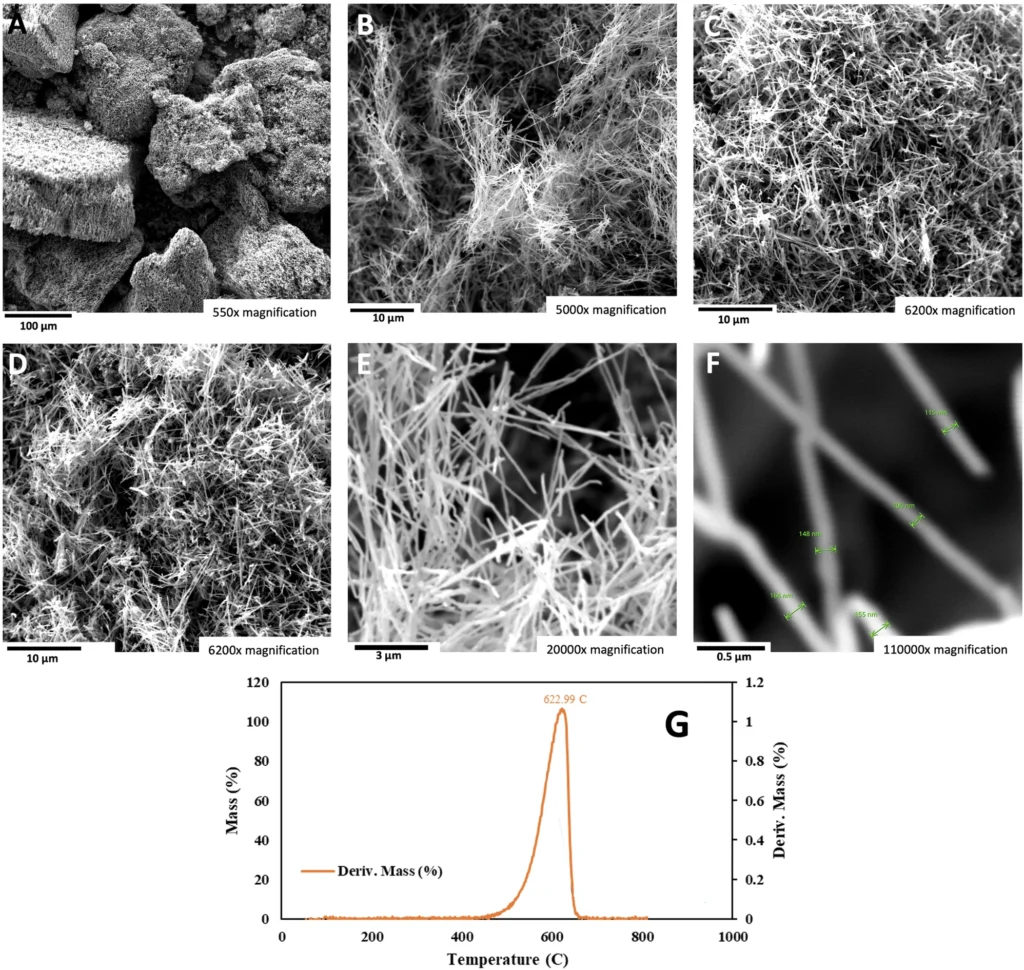

Furthermore, there are regulatory considerations to take into account. Although the new electrolyte is more ecologically benign, to guarantee its safety and adherence to industrial requirements, more testing and certification will be necessary. The carbon nanotube product of electrolysis in a 50 wt% SrCO3/50 wt% Li2CO3 electrolyte.

Anticipated Future Outlook and Areas of Investigation:

Prospects show enormous promise for additional advancements in the decarbonization of molten carbonate. Current investigations are focused on improving the electrolyte’s characteristics by developing more environmentally friendly materials and increasing the overall efficiency of the system. Furthermore, there is an increasing fascination with combining molten carbonate decarbonization with other developing technologies, such as hydrogen generation and sophisticated carbon sequestration techniques.

In conclusion:

The development of a novel electrolyte for decarbonizing molten carbonate signifies a significant advancement in the fight against climate change. By circumventing the constraints of conventional electrolytes, this breakthrough enhances both the effectiveness and ecological footprint of the decarbonization process. As industries strive to minimize their carbon footprints, this novel electrolyte has the potential to significantly contribute to facilitating a cleaner and more sustainable future.

Frequently Asked Questions:

1). What are molten carbonate electrochemical cells (MCEC)?

Molten carbonate electrochemical cells (MCEC) are a type of electrochemical cell. By letting electrochemical reactions happen, electrochemical cells that use molten carbonate electrolytes are made to take CO2 out of industrial processes.

2). What is the comparative performance of this novel electrolyte with conventional alternatives?

The novel electrolyte exhibits enhanced conductivity, increased thermal stability, and a reduced environmental footprint in comparison to conventional electrolytes.

3). Can this novel electrolyte be utilized in current decarbonization systems?

Indeed, this novel electrolyte can be incorporated into current molten carbonate decarbonization systems by making certain adjustments.

4). Which industries will derive the greatest advantages from this technology?

In light of their substantial CO2 emissions and the imperative for effective carbon capture, the power-generating, steel, and cement sectors have the potential to reap substantial advantages.

5). Does the new electrolyte pose any environmental hazards?

Although the novel electrolyte mitigates environmental hazards in comparison to conventional materials, further investigation is necessary to thoroughly evaluate its long-term consequences.

For more chemistry blogs, visit chemistry Master