Table of Contents

The discovery of ultrahigh-molar-mass cyclic polymers is a significant breakthrough in the field of sustainable materials science today. These distinctive polymers, distinguished by their exceedingly high molecular weight and cyclic structure, possess remarkable mechanical qualities and chemical durability, rendering them highly desirable in diverse industries such as aerospace, automotive, and biomedical engineering.

An overview of ultrahigh-molar-mass cyclic polymers

Large molecules known as ultrahigh-molar-mass cyclic polymers consist of repetitive units connected in a closed-loop structure without any loose ends. These architectural designs distinguish them from traditional linear or branching polymers. Their extraordinarily high molecular weight, frequently surpassing millions of kilos per mole, gives them exceptional characteristics such as exceptional strength, durability, and resistance to deterioration.

The importance of these polymers lies in their capacity to transform material design, especially in high-performance applications where sturdiness and dependability are of utmost importance. Ultrahigh-molar-mass cyclic polymers have the potential to produce lightweight and strong components for airplanes or long-lasting implants for medical devices.

Production of cyclic polymers with extremely high molar masses is difficult.

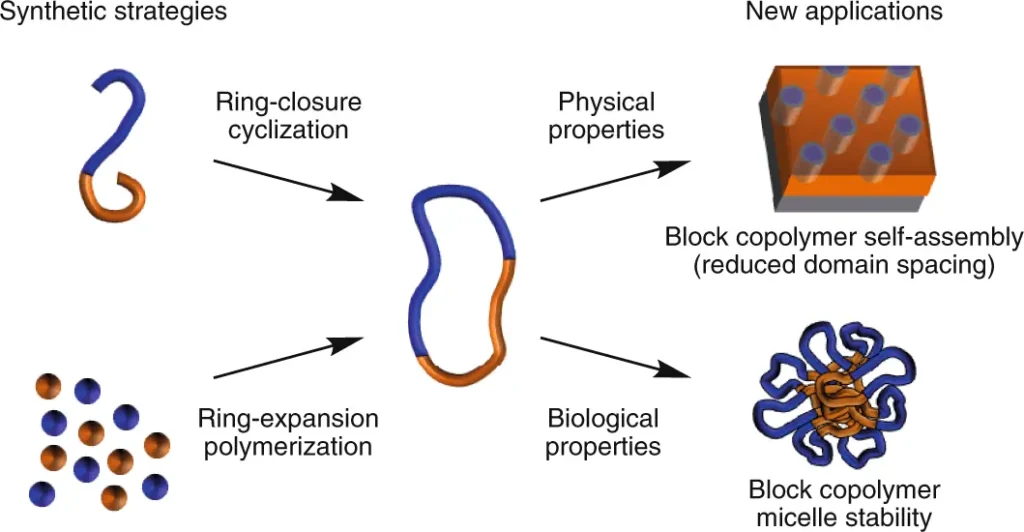

The production of cyclic polymers with extremely high molecular weights poses considerable difficulties due to their large size and complex structure. Conventional polymerization techniques have challenges in successfully generating cyclic molecules of such significant size. The ring-closure phase frequently encounters challenges such as side reactions, partial cyclization, and purifying difficulties, resulting in reduced yields and degraded product quality.

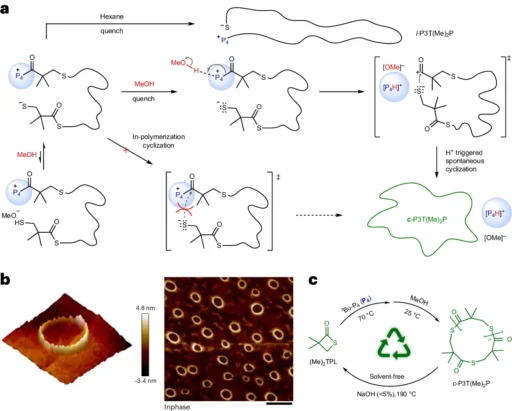

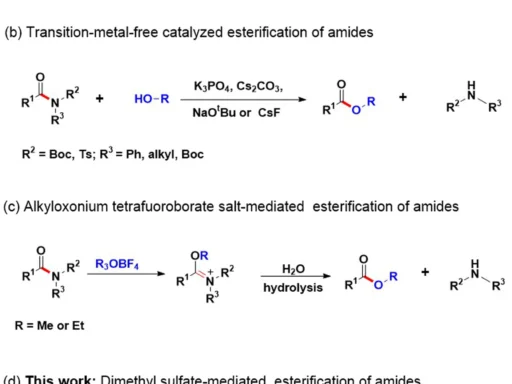

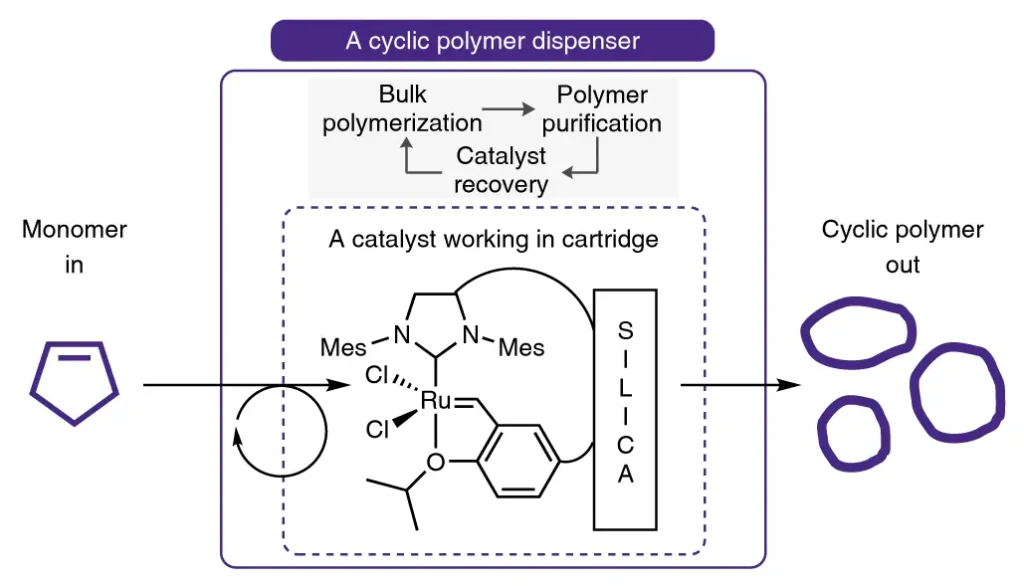

Advanced Methods for Precise Synthesis

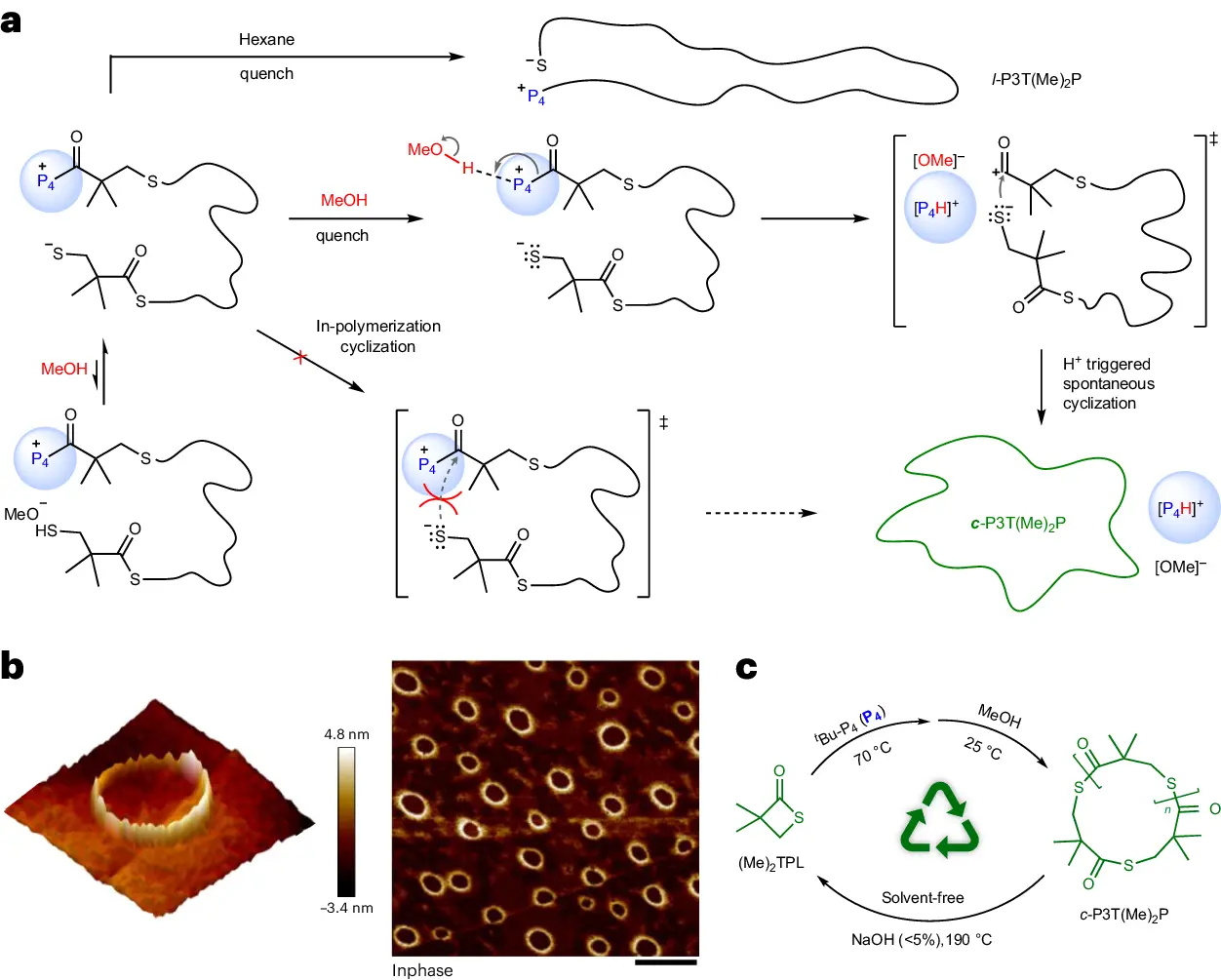

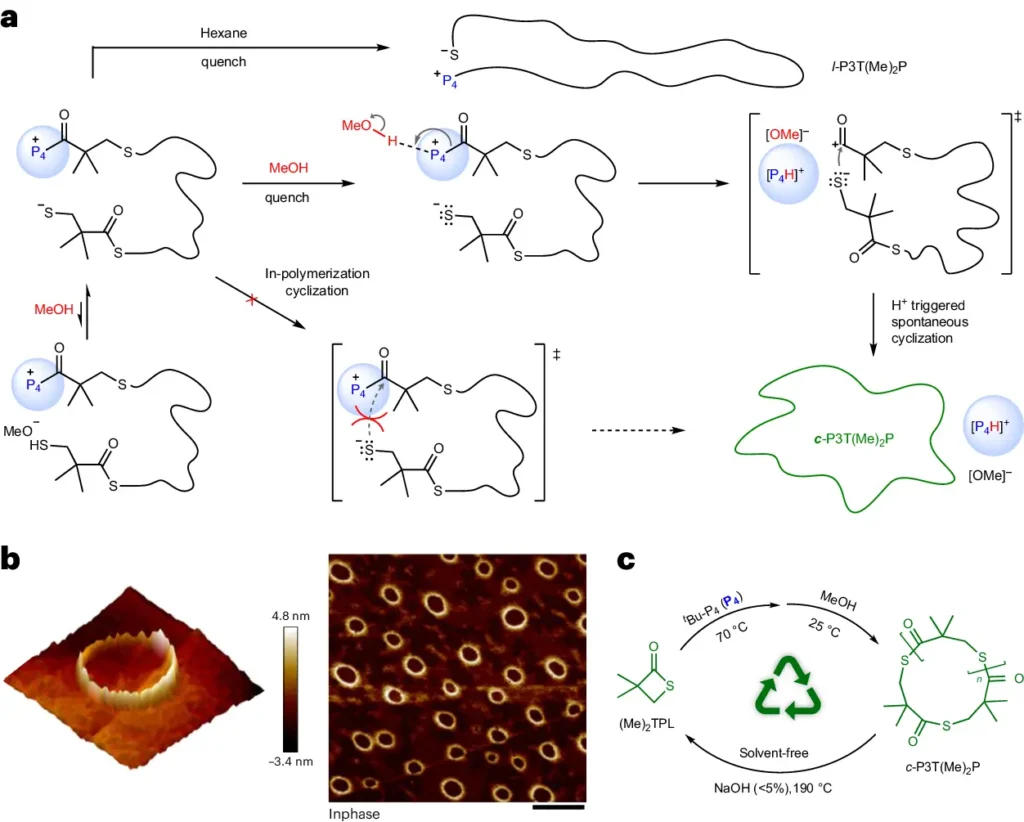

Recent breakthroughs in precise synthesis have successfully addressed numerous obstacles. Controlled polymerization methods, like ring-opening metathesis polymerization (ROMP) and live polymerization, make it possible to make cyclic polymers with very large molecular weights and specific properties. These techniques offer accurate manipulation of molecular weight, structure, and end-group properties, enabling the creation of polymers with specific attributes.

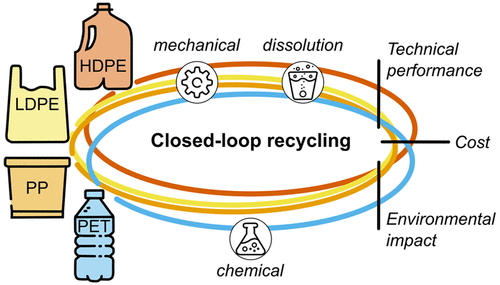

Closed-Loop Recycling: Definition and Need

Closed-loop recycling is a process that recycles and reuses materials to create new products without compromising their quality. It is a sustainable approach that aims to minimize waste and save resources. The need for closed-loop recycling stems from a growing concern about environmental degradation and the finite availability of natural resources.

Innovative Methods for Closed-Loop Recycling

It is important to use closed-loop recycling for long-term management of polymers, especially ultrahigh-molar-mass cyclic polymers. Closed-loop recycling is a method that involves recovering waste materials, transforming them into new goods that are of the same or better quality, and then reintegrating them into the manufacturing process. This strategy aims to minimize resource usage, reduce environmental impact, and encourage the circular use of materials.

Novel approaches to closed-loop recycling

Scientists are creating novel techniques to efficiently recycle ultrahigh-molar-mass cyclic polymers. Researchers can use advanced separation techniques like size exclusion chromatography and mass spectrometry to isolate and purify certain cyclic polymer fractions from complex mixtures. Furthermore, researchers are investigating chemical depolymerization and regeneration methods to transform cyclic polymers back into monomers for re-synthesis.

Advancements in polymer recycling technology

The incorporation of sophisticated analytical methods such as nuclear magnetic resonance (NMR) spectroscopy and high-resolution mass spectrometry is crucial in the process of polymer recycling. These techniques aid in analyzing polymer structures, detecting impurities, and improving recycling operations to attain optimal purity and efficiency.

Major obstacles to closed-loop recycling

Despite advancements in technology, there are still some obstacles that remain in the process of closed-loop recycling of ultrahigh-molar-mass cyclic polymers. Preserving the integrity and excellence of recycled polymers is a substantial challenge due to the risk of deterioration during processing and the existence of impurities. Furthermore, it is crucial to consider the economic feasibility and ability to expand recycling processes to facilitate their wider use in industrial environments.

The future outlook and areas for further study are worth exploring

In the future, the field of ultrahigh-molar-mass cyclic polymers will show great potential. The focus of current research is on developing efficient and cost-effective methods for large-scale material synthesis and recycling. The cooperation of polymer chemists, engineers, and materials scientists is propelling progress towards novel uses, such as improved composites, functional coatings, and environmentally friendly packaging materials.

In conclusion

To summarize, precision synthesis and closed-loop recycling are critical components of the emerging field of ultrahigh-molar-mass cyclic polymers. Researchers are using modern technology and interdisciplinary collaboration to develop sustainable material solutions that have significant consequences for industry and the environment.

FAQ (Frequently Asked Questions)

1). Are there commercially available cyclic polymers with ultrahigh molar masses?

Although there is rapid progress in research in this field, the practical availability of ultrahigh-molar-mass cyclic polymers is still limited because of difficulties in their synthesis and scaling.

2). What are the ecological advantages of closed-loop recycling?

Closed-loop recycling decreases trash production, preserves energy, and lowers the utilization of primary resources, thus promoting environmental sustainability.

Closed-loop recycling can significantly contribute to the circular economy by ensuring that materials are continuously reused and recycled inside the same system, minimizing waste and reducing the need for extracting new resources.

3). How can closed-loop recycling contribute to the circular economy?

Closed-loop recycling helps to establish a circular economy by effectively closing the loop on material utilization, reducing reliance on new resources, and mitigating adverse environmental effects.

4). What are the primary barriers to recycling ultrahigh-molar-mass cyclic polymers?

Primary challenges involve ensuring the integrity of polymer composition, refining recycling methods for widespread implementation, and considering their economic viability.

5). What are the possible future uses of ultrahigh-molar-mass cyclic polymers?

Ultrahigh-molar-mass cyclic polymers show potential for use in sophisticated materials, including high-strength fibers, long-lasting coatings, and biomedical implants.

For more chemistry blogs, visit chemistry Master