Table of Contents

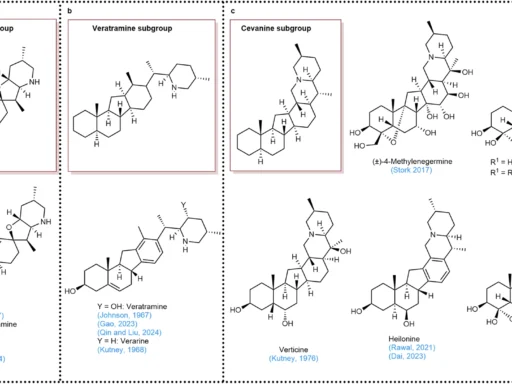

Introduction:

Plastic trash constitutes a significant environmental challenge for contemporary society. Millions of tonnes of plastic contaminating oceans, landfills, and isolated habitats indicate that our existing strategies for managing plastic waste are unsustainable. The demand for novel recycling solutions is at an unprecedented level. One of the advanced solutions to this challenge is the grave-to-cradle dry reformation of polymers by joule heating. This approach presents a viable means to convert plastic trash into useful resources while reducing environmental impact.

Comprehending Plastic Waste Management:

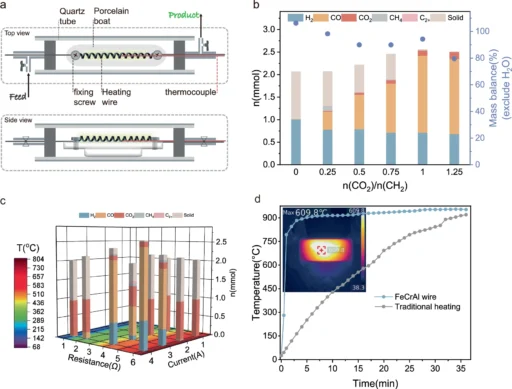

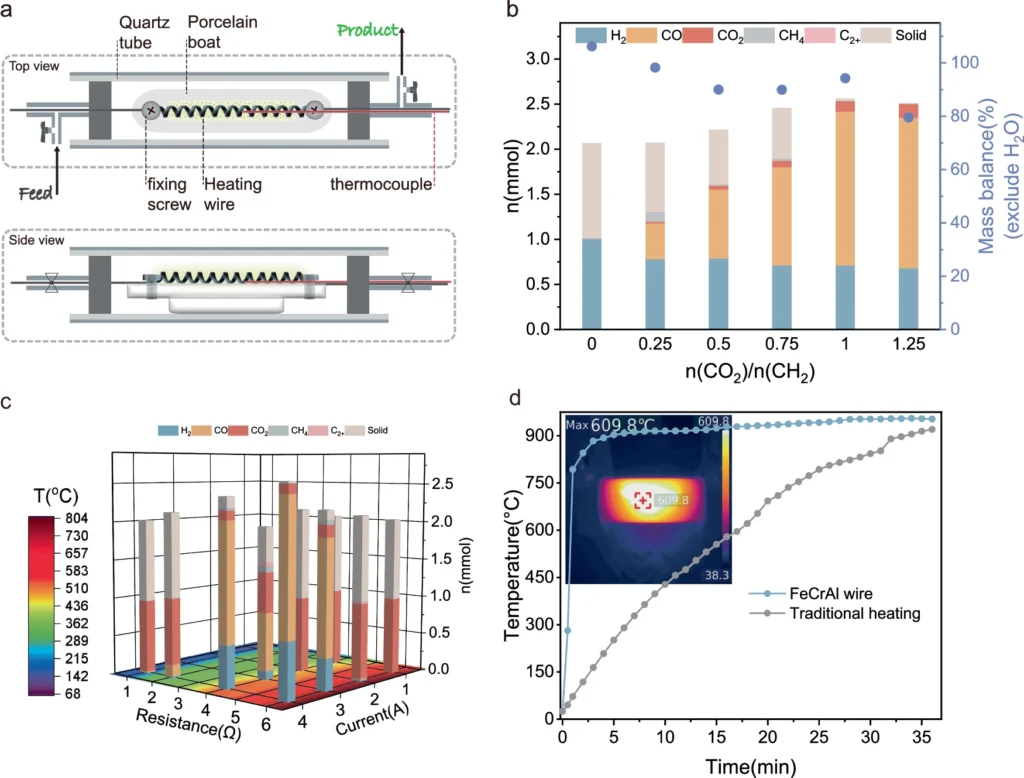

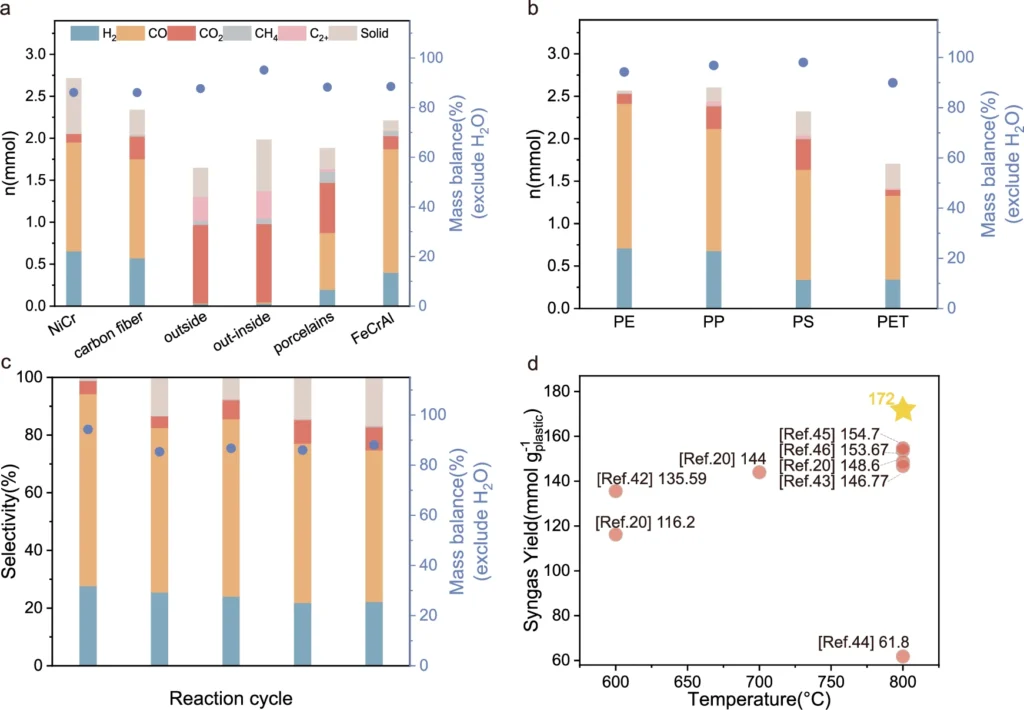

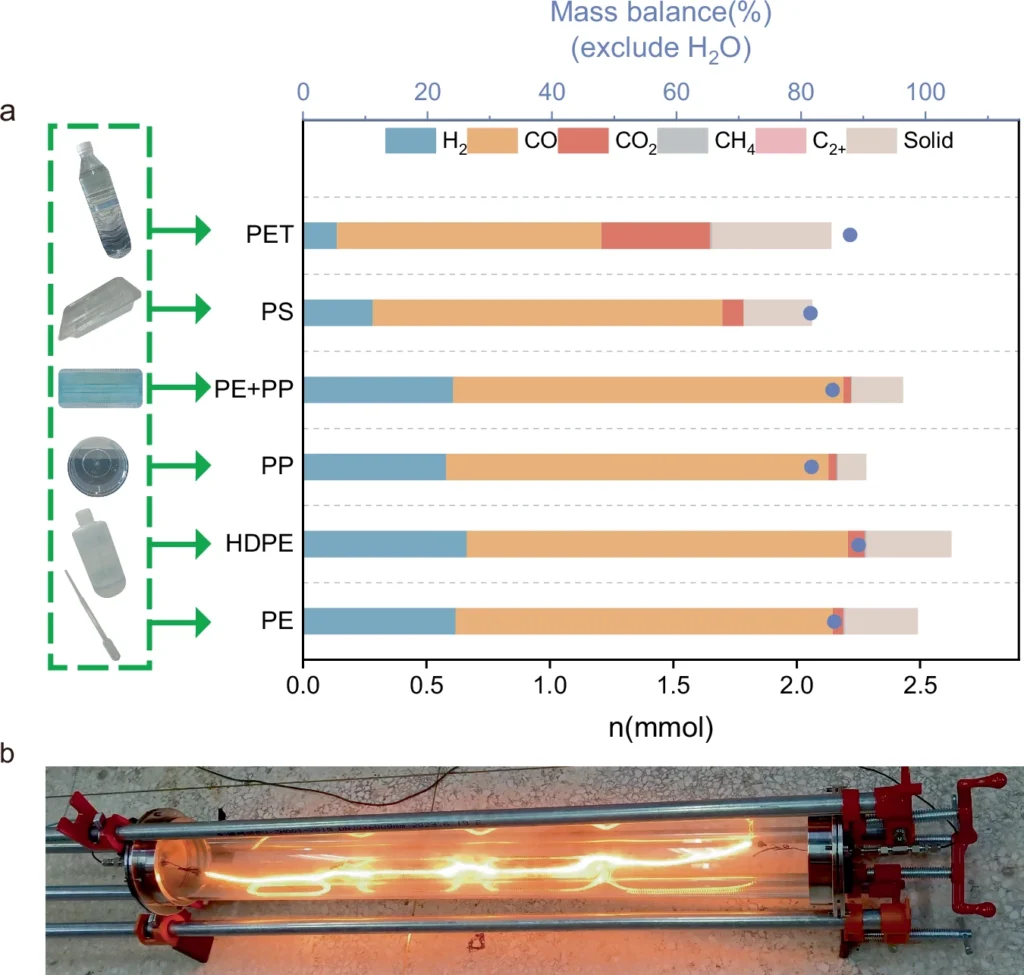

The world produces over 380 million metric tonnes of plastic annually, of which only a small percentage finds its way into recycling. Conventional recycling techniques, such as mechanical and chemical recycling, often display inefficiencies and have limited applicability. The complexity and diversity of plastic waste streams overwhelm these systems, resulting in the disposal of significant quantities of plastic in landfills or burning, which releases harmful gases into the atmosphere. Reactor configuration and reaction conditions screening.

The constraints of current recycling methods include:

Contamination challenges in heterogeneous plastic streams

Downcycling is a process in which recovered polymers lose their quality.

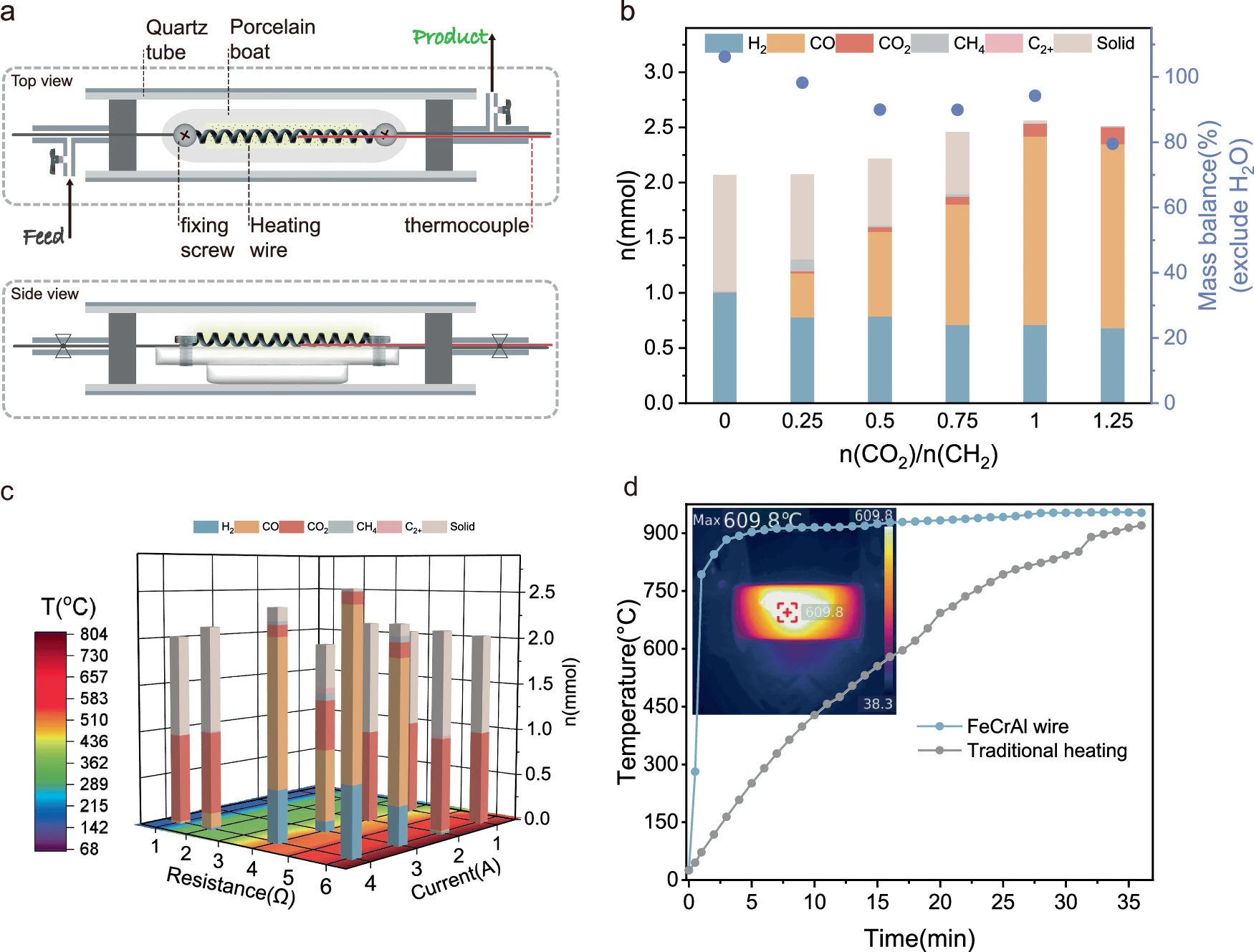

Processes such as pyrolysis or gasification consume more energy.

In light of these issues, there is an increasing interest in identifying alternatives that are both energy-efficient and environmentally sustainable, such as dry reforming.

What is dry reforming?

Dry reforming is a process that utilises carbon dioxide (CO2) to decompose hydrocarbons, such as plastics, creating syngas—a combination of hydrogen and carbon monoxide. This method is particularly beneficial for plastic waste management because it facilitates plastic recycling while also using CO2, a greenhouse gas, as a reactant. It simultaneously tackles two significant environmental issues: plastic pollution and carbon dioxide emissions.

Compared to alternative plastic recycling techniques, dry reforming is

It doesn’t require significant amounts of water, unlike steam reforming.

The technology generates valuable syngas applicable in diverse industrial sectors.

It demonstrates enhanced flexibility in handling diverse types of plastic waste, including difficult-to-recycle polymers. Catalytic performance under various conditions and the contrast with other systems.

Joule Heating’s Function in Dry Reforming:

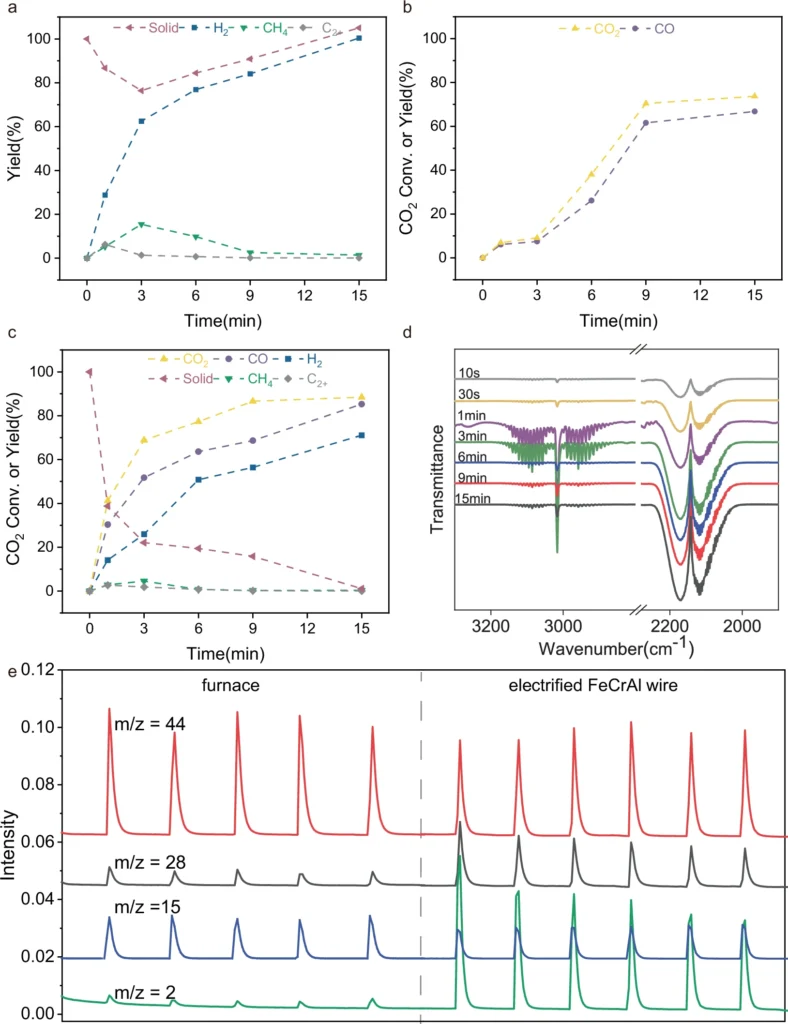

Joule heating, or resistive heating, is a phenomenon in which electrical current traverses a conductor, producing thermal energy. In the realm of dry reforming, joule heating offers a direct and effective method to thermally degrade plastic waste and facilitate the requisite chemical reactions for the reforming procedure.

By applying joule heating, dry reforming can achieve the following:

Exact temperature regulation, enhancing the efficacy of chemical reactions

Compared to conventional heating techniques, energy usage is reduced.

Expedited processing durations make it a viable option for large processes.

Grave-to-Cradle Recycling: What Is Its Significance?

“Grave-to-cradle” refers to a process that transforms waste materials, including plastics, into valuable resources instead of just disposing of them after use. This approach is distinct from the traditional “cradle-to-grave” method, which involves the manufacturing, use, and subsequent disposal of items, often in landfills. Grave-to-cradle systems seek to establish a circular economy by perpetually reusing waste materials.

This differs from the well-known “cradle-to-cradle” methodology, which emphasises the design of products that may be entirely recycled or biodegraded without causing environmental damage. Grave-to-cradle dry reforming innovatively repurposes waste materials at the end of their lifecycle through a highly efficient process. Catalytical performance for real plastic products and scale-up experiment.

Principal Reactions in Plastics Dry Reforming:

The dry reforming process fundamentally involves chemical interactions between polymeric hydrocarbons and CO2. These processes decompose long-chain polymers in plastics into smaller molecules such as hydrogen (H2) and carbon monoxide (CO), collectively referred to as syngas. Syngas is a significant resource, widely used in the manufacture of chemicals, fuels, and many industrial products.

The following reaction illustrates the procedure:

Plastic (hydrocarbons) + CO2 => H2 + CO

Plastic (hydrocarbons) + CO2 => H2 + CO

Using CO2 as a reactant is a significant benefit, as it facilitates carbon sequestration while generating valuable products.

Benefits of Dry Reforming Compared to Alternative Plastic Recycling Techniques:

Dry reforming, particularly when integrated with joule heating, presents numerous benefits:

Enhanced energy efficiency: Reduced energy is necessary to commence and maintain the process in comparison to techniques such as incineration or pyrolysis.

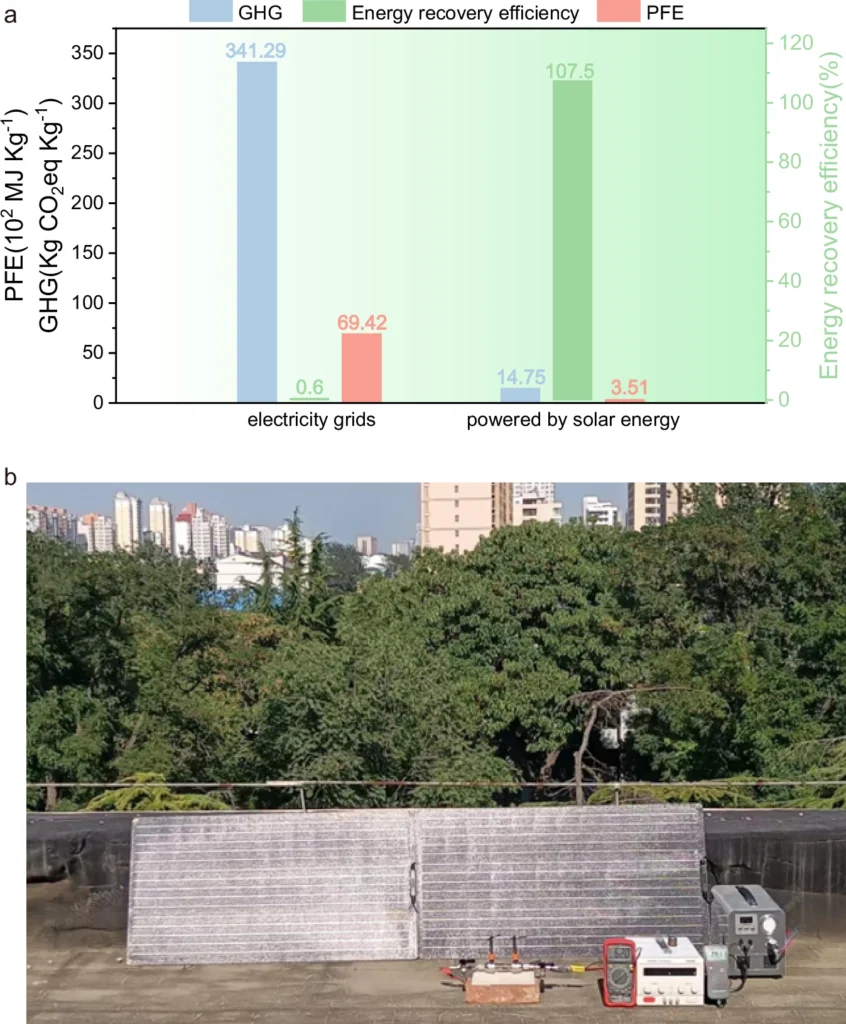

Ecological advantages: Dry reforming mitigates greenhouse gases by using CO2 and lowering methane emissions.

Versatility: The process is capable of managing heterogeneous and polluted plastic trash, presenting a considerable barrier for conventional recycling techniques.

Barriers in the Dry Reforming Process for Plastics:

Despite its potential, dry reforming plastic presents several obstacles. These encompass:

Material constraints: Not all plastics are equally appropriate for the procedure, and certain types necessitate pretreatment.

Scalability: Although joule heating is effective at lower sizes, its industrial application necessitates surmounting considerable technical challenges.

Cost: Despite the process’s energy efficiency, the initial capital expenditure for the Joule heating apparatus may be substantial. Catalysis kinetics parameters and the in-situ FTIR, MS analyses.

Joule Heating: A Revolutionary Advancement in Plastic Waste Recycling

Joule heating is a revolutionary technology for dry reforming plastic waste recycling. The direct energy transfer approach enables faster and more efficient heating, reducing both the time and energy required for the associated chemical reactions.

Furthermore, joule heating provides exceptional control over reaction parameters, enabling precise adjustments of temperature and reaction rate, which is essential for maximising syngas production.

Technological advancements in joule heating for dry reforming:

Joule heating’s recent advancements are improving its appeal for plastic recycling. These encompass:

Advanced materials: We use advanced electrode materials that improve the durability and efficiency of the heating process.

The integration of automation and artificial intelligence allows for greater control over the reforming process while minimizing human interaction.

Systems for energy recovery utilize excess heat to improve the system’s overall energy efficiency.

Case Studies: Effective Implementations of Dry Reforming via Joule Heating

Numerous businesses have begun investigating the possibility of dry reformation using joule heating. Certain chemical industries have effectively implemented technologies to transform plastic trash into profitable syngas, thereby decreasing their dependence on fossil fuels and lessening their environmental impact. These initial achievements illustrate the feasibility of the technique on a broader scale.

Ecological Consequences of Grave-to-Cradle Recycling via Dry Reforming:

A principal advantage of this procedure is its beneficial effect on the environment. Dry reforming mitigates plastic pollution and greenhouse gas emissions by transforming plastic waste into valuable products while employing CO2. Gradual widespread implementation of this technology may result in a significant decrease in plastic trash and its related ecological detriments.

Joule Heating in Plastic Recycling: Economic Feasibility

In plastic recycling, the economic rationale for joule heating is persuasive. Despite elevated initial setup expenses, the long-term advantages of energy savings and the value of syngas generated can mitigate these costs. Furthermore, as the technology advances, economies of scale may render dry reforming using Joule heating a progressively appealing alternative for enterprises aiming to handle their plastic waste more responsibly. Life cycle assessment of the reforming system and a demo configuration using solar energy.

The Prospects of Plastic Waste Recycling:

With the rising worldwide awareness of the plastic waste challenge, there is a heightened interest in technology that provides sustainable solutions. Joule heating-based dry reforming represents a significant advancement in this field, providing an efficient method for plastic recycling while simultaneously decreasing CO2 emissions. Through sustained innovation and investment, this technology may significantly influence the future of plastic waste management.

Final Assessment:

The grave-to-cradle dry reformation of plastics by joule heating signifies a groundbreaking advancement in combating plastic waste. This technology utilises CO2 and the effectiveness of joule heating to provide a scalable, eco-friendly answer to a pressing global issue. Despite existing hurdles, the capacity of this technology to revolutionise plastic waste recycling is substantial, positioning it as a crucial element in the shift towards a more sustainable future.

Frequently Asked Questions:

1). What makes dry reforming a superior technique for plastic recycling?

Dry reforming exhibits greater energy efficiency and accommodates a broader spectrum of polymers, particularly those challenging to recycle through conventional processes.

2). In what manner does Joule heating enhance the efficiency of dry reforming?

Joule heating improves process efficiency by facilitating accurate temperature regulation, accelerating reactions, and reducing energy consumption.

3). What are the primary obstacles to this technology’s expansion?

Material constraints, elevated startup costs, and technical obstacles to expanding the process for industrial applications are the principal issues.

4). Is joule heating more environmentally sustainable than conventional methods?

Indeed, joule heating diminishes energy usage and greenhouse gas emissions, rendering it a more sustainable alternative for plastic recycling.

5). Is this procedure applicable to all varieties of plastics?

Although the method is adaptable, not all plastics are equally appropriate for dry reforming. Certain cases may require pretreatment to ensure the best results.

For more chemistry blogs, visit chemistry Master