Table of Contents

Liquid marbles, a fascinating development in materials science, comprise tiny liquid droplets encased in a hydrophobic particle shell. These characteristics, which make them very stable, transportable, and adaptable, enable their use in a wide range of scientific research, industry, and technological applications.

An overview of liquid marbles:

Hydrophobic particles cover small liquid droplets, ranging from micro- to nanoscale, to create a spherical shell, a distinctive method of encapsulation known as liquid marbles. The outer layer serves as a protective barrier, preventing the liquid core from evaporating or combining with other substances. This leads to the formation of small, self-contained organisms with fascinating characteristics. Liquid marbles have attracted considerable attention because of their possible uses in several sectors, such as microfluidics, biotechnology, environmental science, and more.

Production of Durable Single-Layer Liquid Marble:

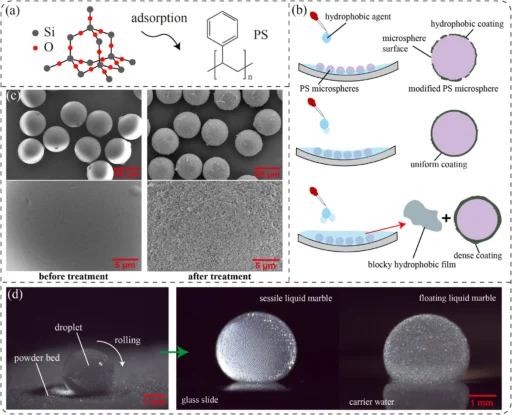

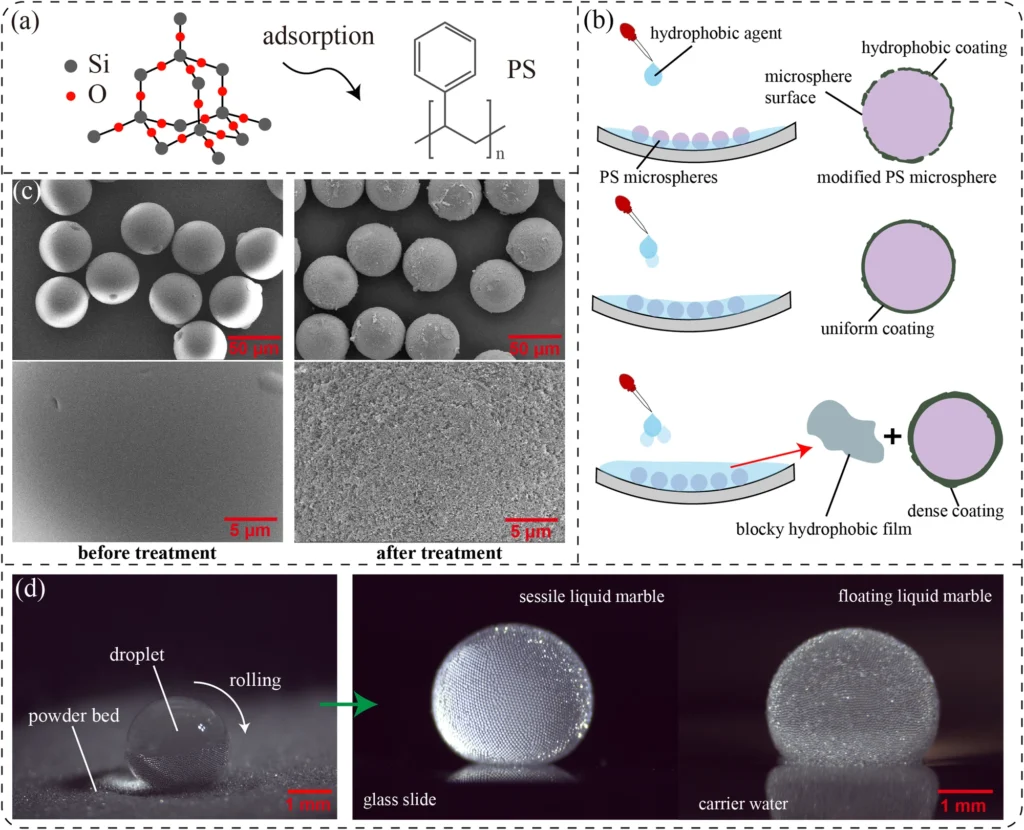

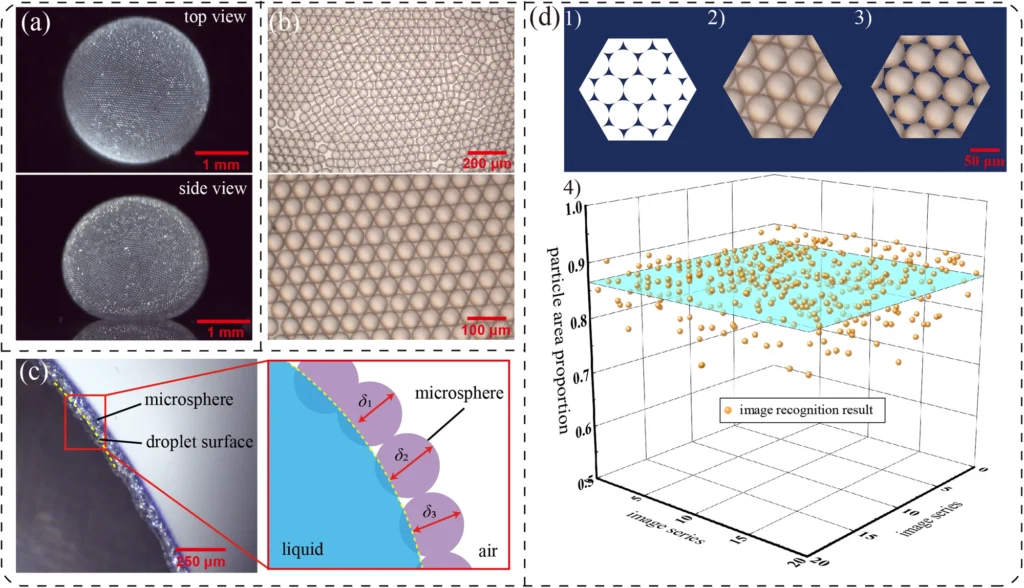

A precise procedure is required to produce stable monolayer liquid marbles, to achieve a consistent particle distribution and minimize clumping. The main difficulty lies in guaranteeing that the hydrophobic particles create a seamless monolayer over the liquid droplet, improving stability without sacrificing mobility. Scientists use various methods, such as controlled deposition and surface modification, to improve the manufacturing process and customize the characteristics of liquid marbles for specific applications. The process of particle treatment and formed LMs.

Hydrophilic Surfaces and Locomotion:

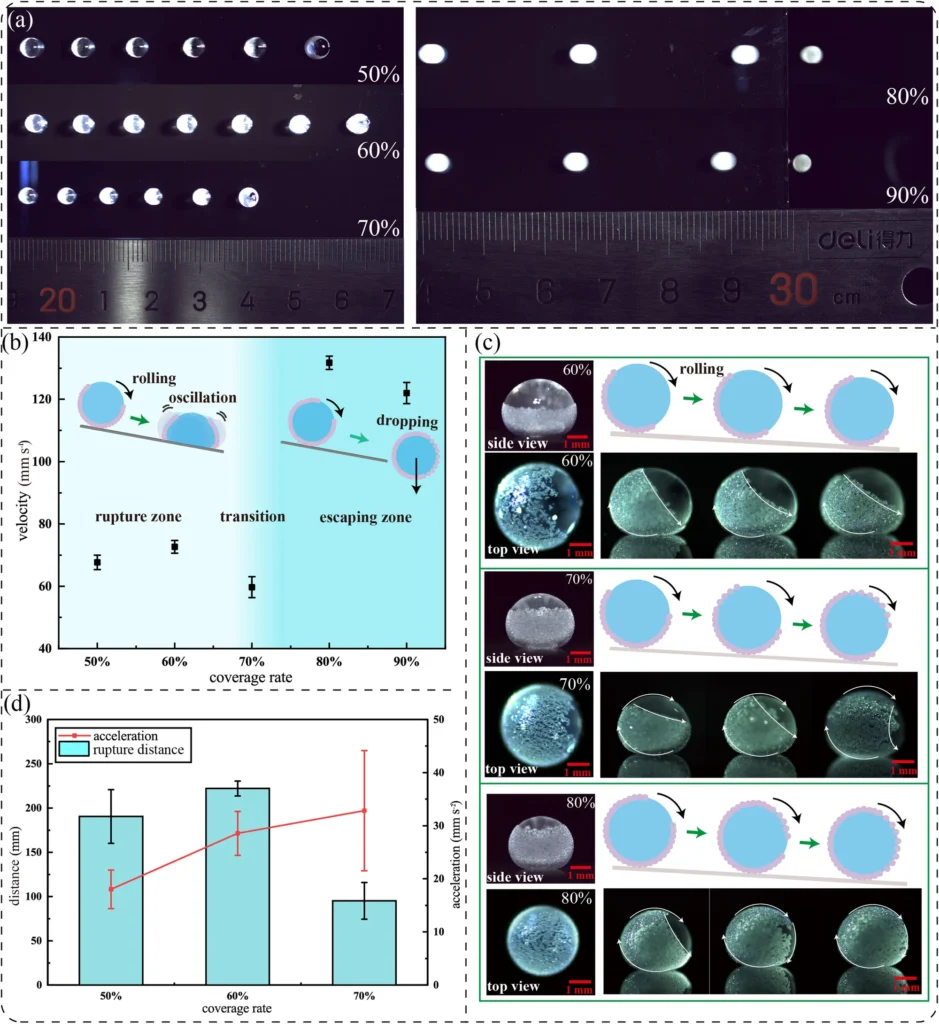

The behavior of liquid marbles on hydrophilic surfaces is one of their notable aspects. Differences in surface tension cause liquid marbles to display fascinating movement patterns when placed on certain surfaces. The hydrophobic shell of the marble interacts with the hydrophilic surface, causing controlled motion that resembles small, self-propelled creatures. This distinctive feature provides opportunities for applications in micro-robotics, precise fluid manipulation, and surface engineering.

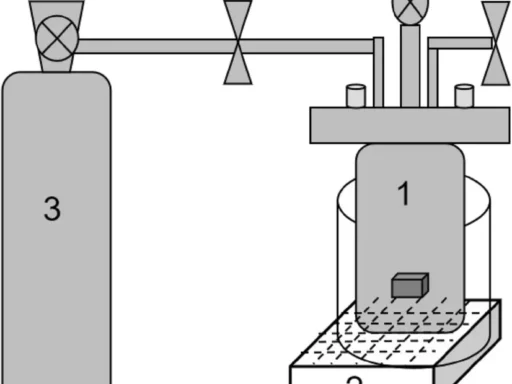

Experimental Procedures:

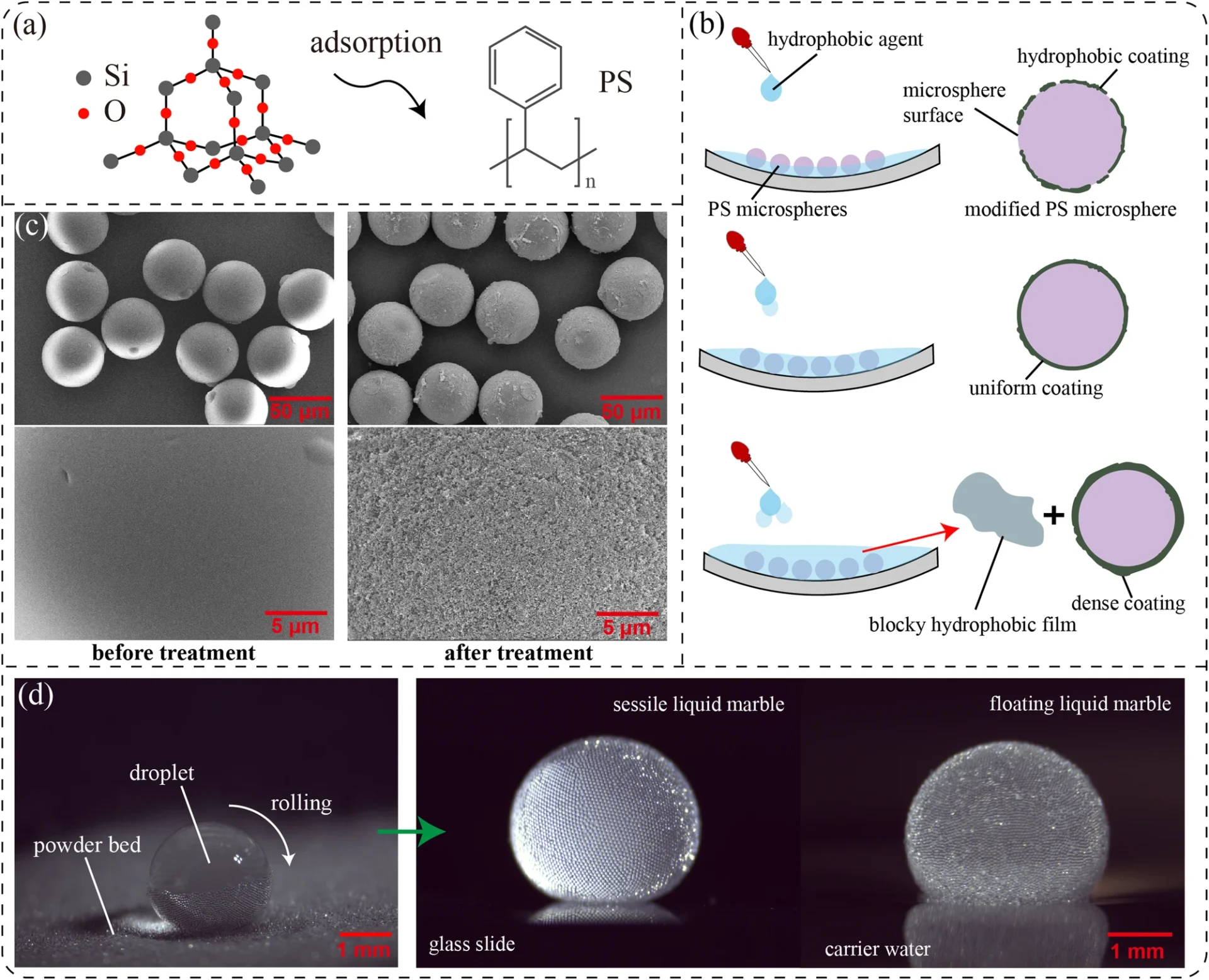

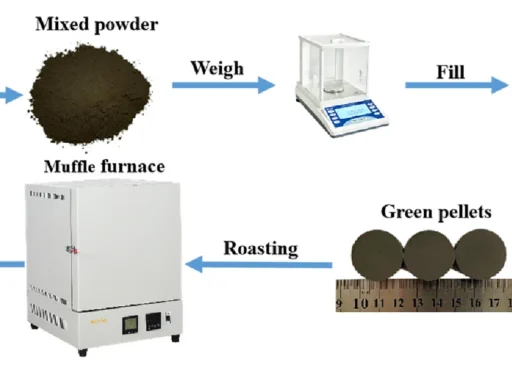

Special materials and processes are required to create stable, monolayer liquid marbles with the appropriate features. People frequently employ hydrophobic particles, like silica or polymer microspheres, to coat liquid droplets. The dimensions, constitution, and density of these particles play an important role in determining the stability and movement of the resulting liquid marbles. We use methods like drop deposition, particle rolling, or electrostatic assembly to ensure consistent particle distribution and enhance the characteristics of marble.

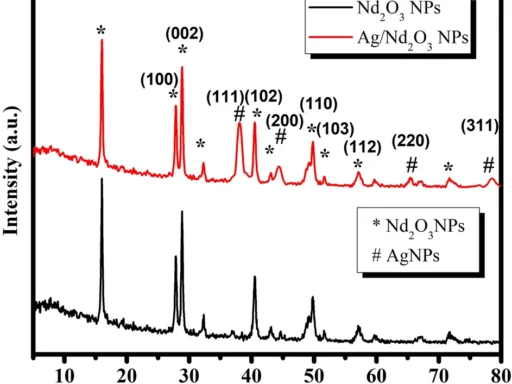

Methods for Characterization:

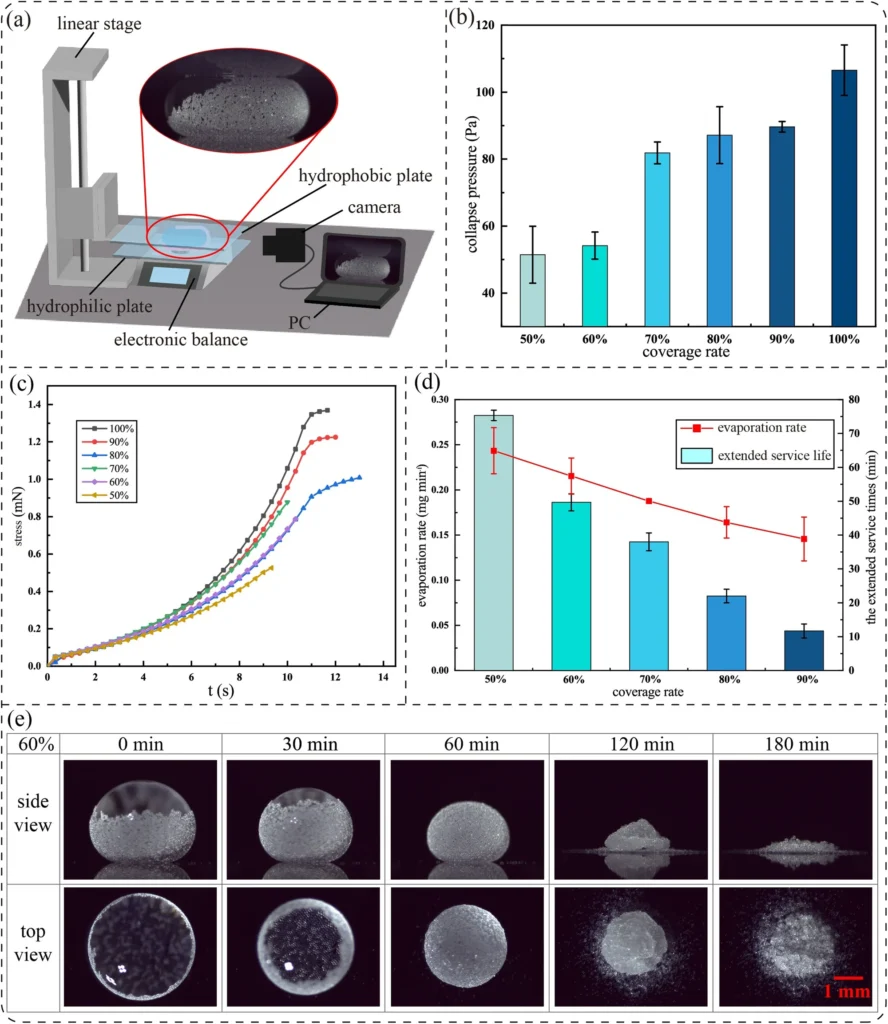

Researchers use sophisticated characterization approaches to assess liquid marbles’ stability, motility, and other attributes. High-resolution microscopy, contact angle measurements, and surface analysis approaches offer useful insights into the movement and interactions of marble on various surfaces. Characterization is critical for understanding the fundamental mechanisms that regulate the behavior of liquid marbles and for optimizing their performance in different applications. Stability and service life of LMs with different opening areas.

Factors affecting stability:

Various factors impact the stability and longevity of liquid marbles. Several factors determine marble qualities, including particle size distribution, particle-to-liquid ratio, ambient circumstances (such as humidity and temperature), and the nature of the liquid core. These factors are critical in shaping marble’s characteristics. By optimizing these parameters, researchers can develop customized liquid marble formulations that are appropriate for certain applications, ranging from microfluidic devices to the production of new materials.

Uses of Stable Monolayer Liquid Marble:

Stable, monolayer liquid marbles offer a wide range of applications in various sectors and research fields.

1). Microfluidics: Liquid marbles are highly efficient microreactors for chemical synthesis and biological experiments, allowing for fine manipulation of fluid management and reaction kinetics.

2). Biomedical Engineering: Researchers are studying liquid marble for their potential use in drug delivery, especially when precise control over the release of medication and its targeting to specific areas is crucial for optimal therapeutic effectiveness.

3). Environmental remediation could potentially use liquid marbles, which offer creative ways to contain pollutants and control their release.

4). Surface engineering could use liquid marble to create hydrophobic coatings or self-cleaning surfaces.

5). Liquid marbles can be included in micro-robotic systems to enable independent movement and manipulation at small sizes by utilizing their locomotive features.

Liquid marbles possess distinctive attributes such as stability, mobility, and adaptability, which render them highly promising for driving advancements in diverse technological domains. Monolayer particle shell characterization:

Dynamic characterization of LMs with opening areas:

Prospects and Areas for Future Investigation:

Ongoing research in liquid marble technology is positioned to provide fresh opportunities and tackle current obstacles. Possible future avenues may encompass:

a). Enhanced Locomotion Mechanisms: We are investigating innovative techniques for regulating and maximizing the movement of liquid marble on various types of surfaces.

b). Biocompatible Formulations: The objective is to create liquid marble formulations that are compatible with living organisms, specifically for use in biomedical applications like targeted medication administration and tissue engineering.

c). We are exploring microfluidic systems with integration: utilizing liquid marble in intricate microfluidic devices to improve functionality and performance.

d). Environmental Applications: We are utilizing liquid marble for environmental monitoring, cleanup, and sustainable technologies to broaden their application in the field.

We anticipate that research in these fields will accelerate progress in materials science, fluid dynamics, and multidisciplinary research, leading to revolutionary applications of liquid marble technology.

In conclusion:

To summarise, the creation of stable monolayer liquid marble is a notable intersection of materials science, surface chemistry, and fluid dynamics. These microscale organisms possess remarkable stability and mobility, making them valuable tools in scientific research, industrial applications, and technological innovation. As research progresses in the field of liquid marble technology, we expect more significant advancements and the development of new applications that utilize the distinct features of these intriguing microstructures.

Frequently Asked Questions:

1). What are the distinguishing characteristics of liquid marble compared to standard droplets?

Unlike regular droplets, hydrophobic particles envelop liquid marble, creating a shielding layer that improves both stability and movement.

2). Are liquid marbles appropriate for biomedical applications?

Liquid marbles have potential in drug delivery and tissue engineering because of their ability to release substances in a controlled manner and their compatibility with biological systems.

3). Which kinds of particles go into making liquid marbles?

Liquid marbles frequently receive a coating from hydrophobic particles like silica or polymer microspheres, which enhances their characteristics.

4). What is the impact of hydrophilic surfaces on liquid marble motion?

When hydrophilic surfaces interact with the hydrophobic outer layer of liquid marble, they move on purpose and make it easier for them to move in unique ways.

5). What are the environmental consequences of using liquid marble?

Liquid marble has the potential to provide solutions for environmentally sustainable technology, including pollutant encapsulation and controlled release, thereby reducing ecological harm.

For more chemistry blogs, visit chemistry Master.