Table of Contents

Assessing the use of modified chitosan composites in acidic reservoirs through pilot and field-scale simulation studies is a significant advancement in oil reservoir engineering. It aims to improve oil recovery and reservoir management. This article delves into the diverse applications of modified chitosan, a chitin-derived substance, in addressing the challenges posed by acidic conditions in oil reservoirs.

An overview of modified chitosan:

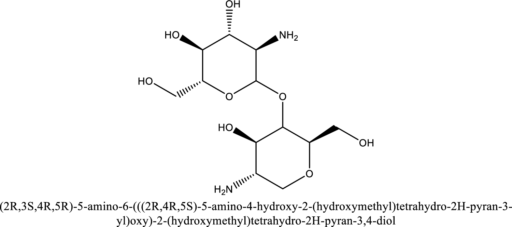

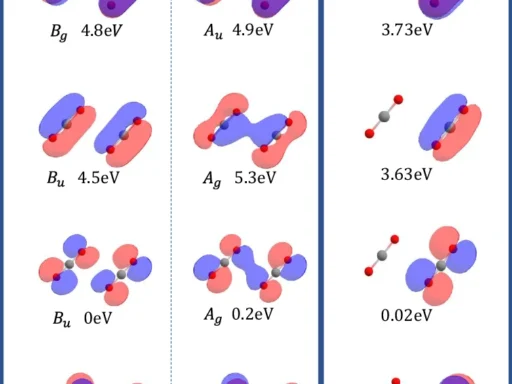

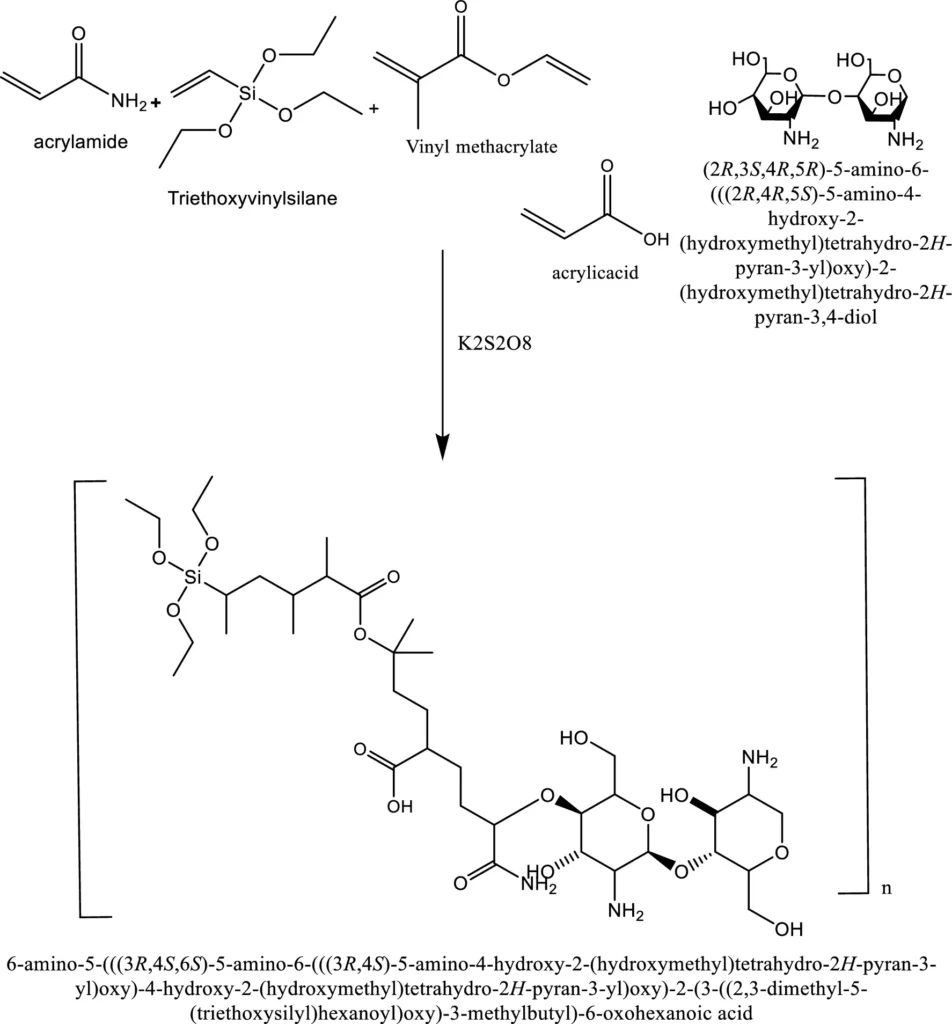

Researchers extensively research chitosan, a modified form of chitin, a natural polymer present in the exoskeletons of crustaceans and insects, for its distinct features and various uses. Chitosan possesses biocompatible, non-toxic, and biodegradable properties, which make it very desirable for a wide range of industrial and biomedical applications. Modified chitosan has potential in oil reservoir engineering because it can endure the acidic conditions found in specific reservoir locations. Chitosan chemical structure.

Characteristics and Significance of Acidic Reservoirs: Chitosan’s molecular structure influences its characteristics, and chemical alteration can adjust it to enhance specific functionalities. Acidic reservoirs, which have low pH levels due to the presence of organic acids or mineral dissolution, pose a challenge for conventional oil extraction techniques. Modified chitosan’s enhanced acid resistance makes it an attractive option for reservoir engineering applications, intending to improve oil recovery rates and reservoir performance.

Issues encountered with acidic reservoirs:

Acidic reservoirs pose many difficulties that affect the efficiency of oil extraction operations and the tactics employed for reservoir management. Microbial activity, the generation of organic acids, and mineralogical properties influence reservoir acidity. These conditions may result in reduced permeability, heightened corrosion hazards, and suboptimal rates of oil extraction.

Effect on Oil Extraction:

The reservoirs’ acidic character can have negative effects on oil recovery procedures by modifying rock qualities, decreasing fluid mobility, and encouraging corrosion in wellbore and equipment. Therefore, it is crucial to implement efficient measures to minimize the negative impacts and maximize the productivity of oil extraction, thus guaranteeing the long-term viability of reservoir resources.

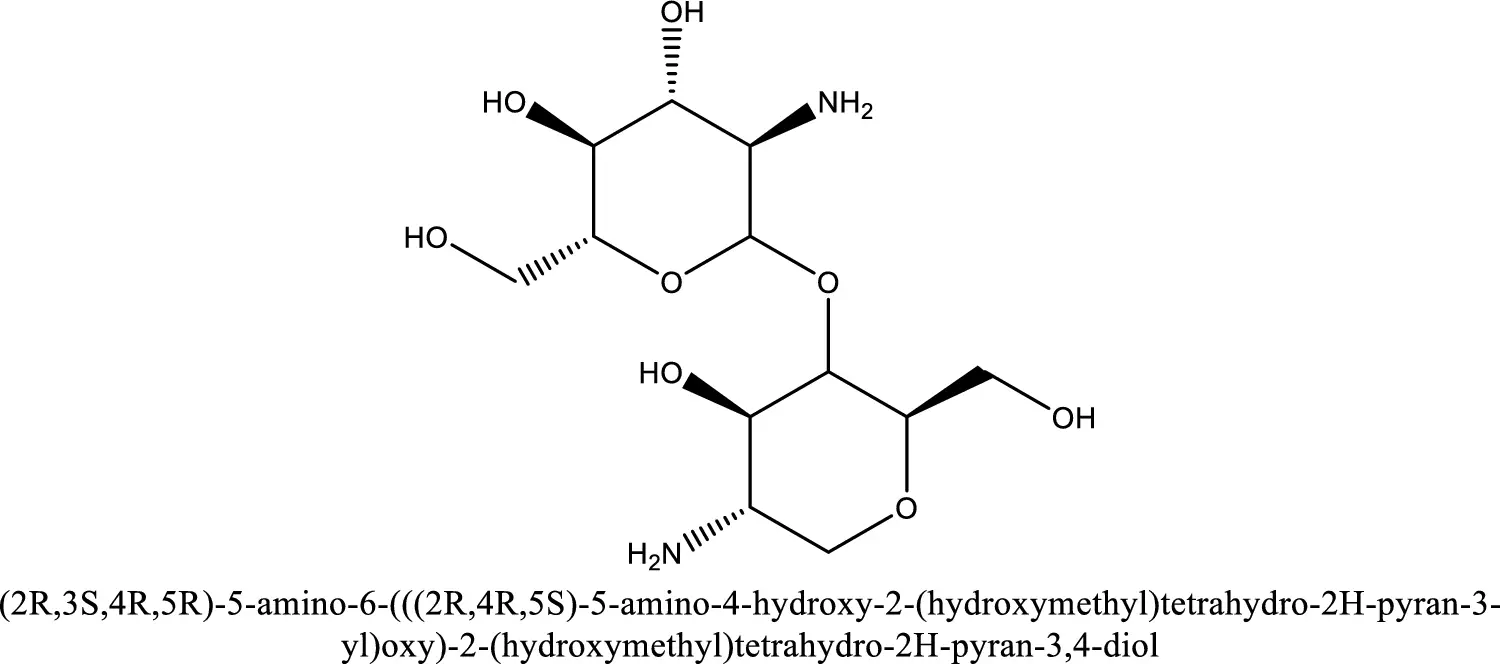

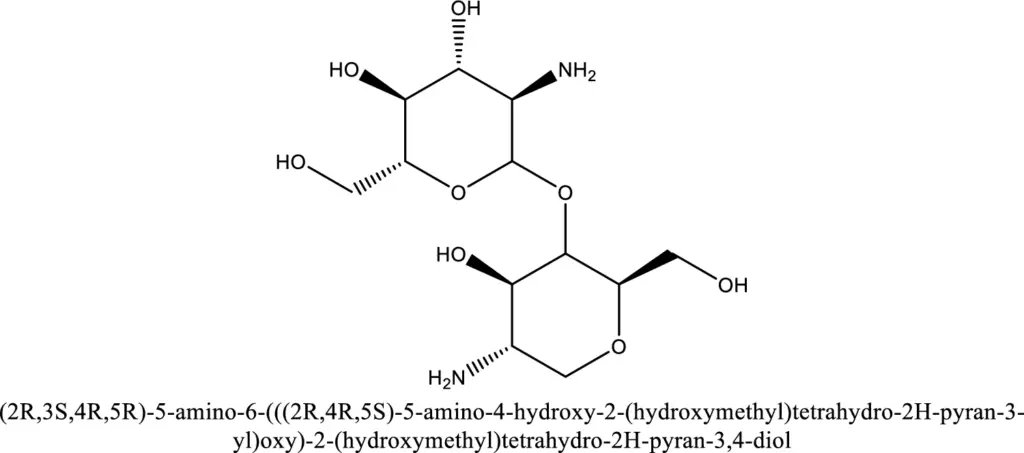

Chemical structure of modified chitosan composite.

This article discusses the role of chitosan in reservoir applications:

Chitosan plays a significant role in reservoir applications that go beyond the typical chemical treatments used for acidizing and improved oil recovery (EOR). Modified Chitosan’s distinctive characteristics allow it to alter the wetness of reservoirs, regulate the movement of fluids, and prevent corrosion. As a result, it improves the effectiveness of oil recovery operations.

The application of chitosan in the process of oil recovery:

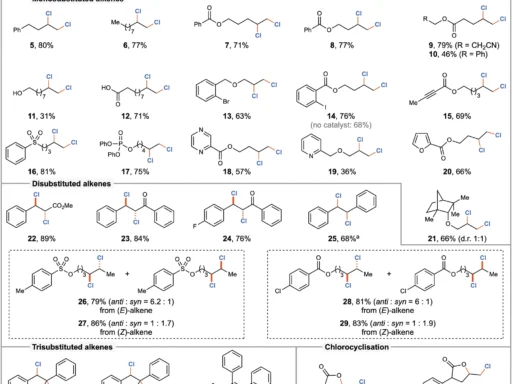

Researchers have conducted extensive research on chitosan-containing formulations for their potential use in enhanced oil recovery (EOR) applications. Research has shown that chitosan can modify the way fluids and rocks interact, enhance the effectiveness of fluid displacement, and decrease the amount of oil that remains trapped, resulting in higher oil extraction rates.

Advantages of Modification:

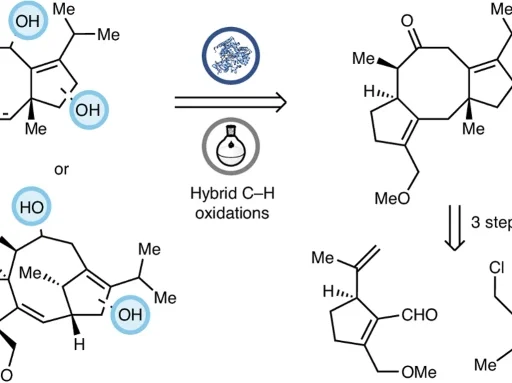

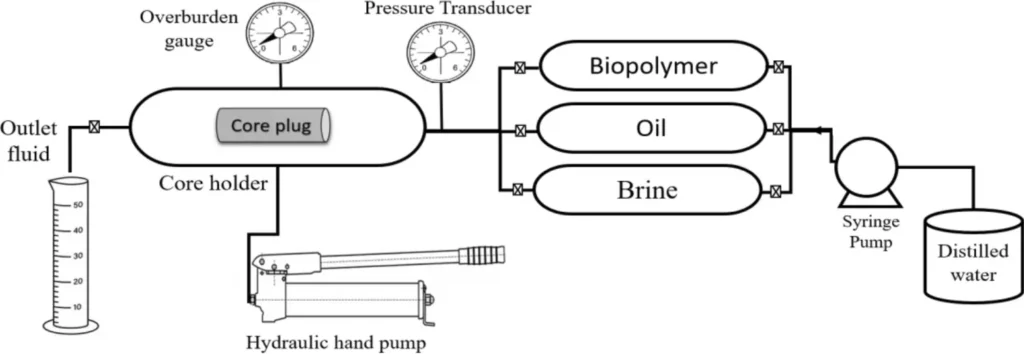

Chemical modification improves chitosan’s performance and adaptability to specific reservoir conditions. Modifications such as cross-linking, grafting, or blending with other polymers might enhance the effectiveness of the material in acidic conditions by adding more functions. Schematic representation of Core flood system.

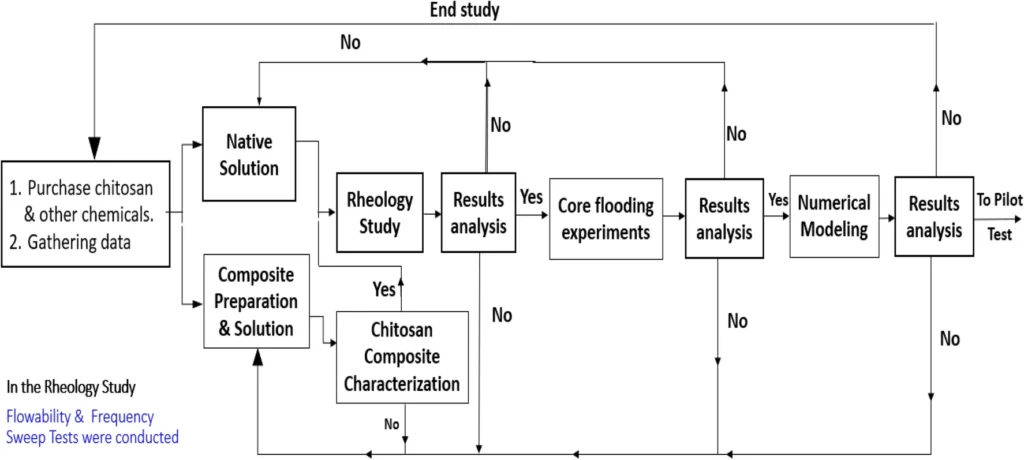

Studies on pilot simulation:

Pilot studies are essential for assessing the viability and efficacy of chitosan-based therapies in reservoirs with acidic environments. These investigations entail conducting small-scale tests in controlled laboratory settings to replicate reservoir conditions and evaluate the effectiveness of modified chitosan composites.

The design and procedures used to experiment:

Pilot simulation studies typically entail creating experiments that replicate reservoir conditions, including temperature, pressure, and fluid composition. We apply chitosan formulations to evaluate their impact on reservoir parameters such as permeability, wettability alteration, and oil displacement efficiency.

Analysis and Notable Discoveries:

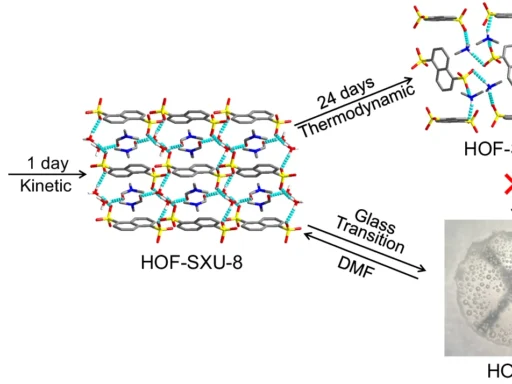

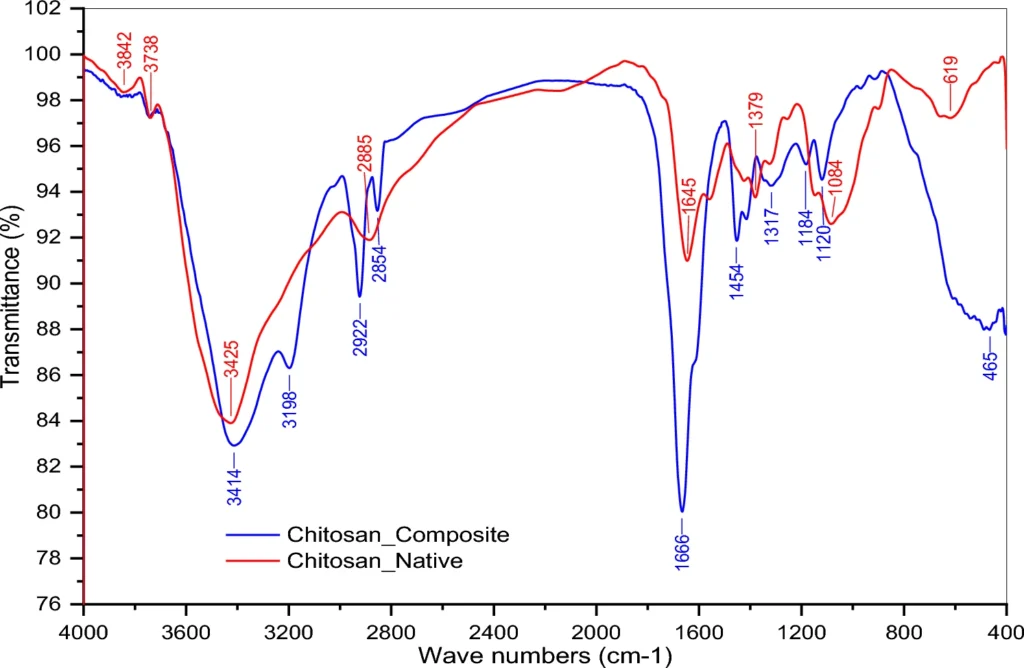

Pilot studies yield useful insights regarding the most effective formulation and application settings for chitosan-based therapies. The main discoveries may consist of enhancements in the efficiency of sweeping the reservoir, increased rates of recovering oil, and a reduction in reservoir acidity. FTIR of native and composite chitosan.

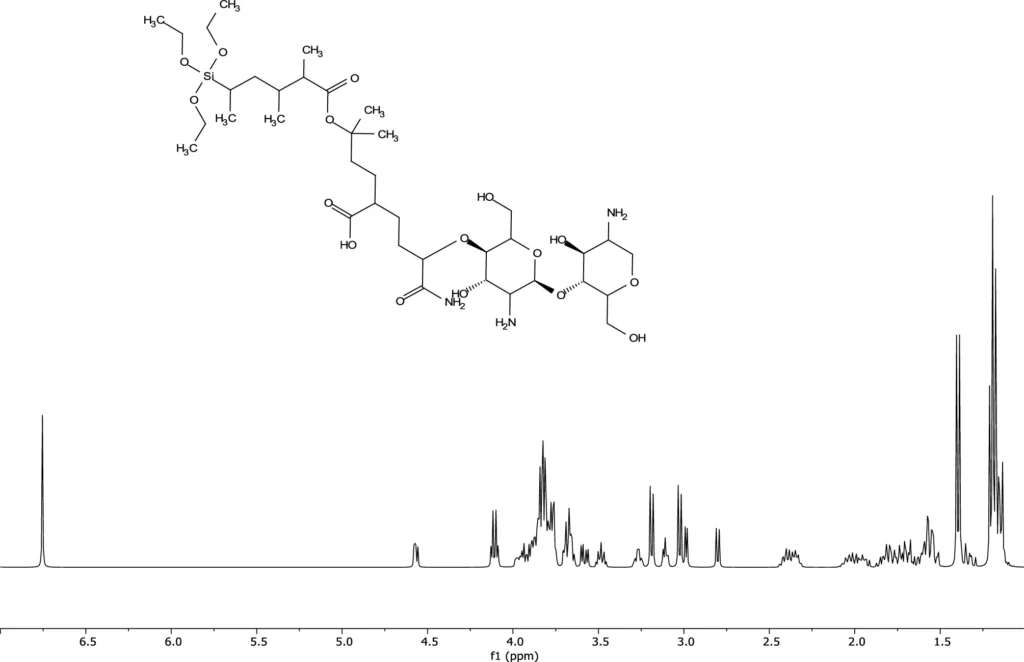

Proton 1H NMR spectra for chitosan composite.

These studies involve the simulation of large-scale fields:

Based on the positive outcomes of initial testing, large-scale modeling simulations confirm that chitosan-based treatments are both scalable and practicable for use in real-life reservoir applications. These investigations aim to assess the long-term effectiveness and economic feasibility of chitosan composites in improving oil recovery.

Expanding the scope of research from pilot studies:

To move from pilot to field-scale investigations, it is necessary to increase the scale of chitosan treatments must be scaled up to align with the intricate and diverse nature of real reservoirs. Field-scale evaluations take into account factors such as injection tactics, reservoir heterogeneity, and long-term performance.

Practical Implementation and Outcomes:

Field-scale simulation studies yield valuable data regarding the effectiveness of chitosan composites in various reservoir conditions. We evaluate performance criteria such as incremental oil recovery, reservoir pressure maintenance, and treatment lifespan to assess the practicality and cost-effectiveness of chitosan-based techniques.

We are evaluating the performance of a Modified chitosan composite:

We thoroughly evaluate the efficacy of modified chitosan composites by their capacity to neutralize reservoir acidity, promote fluid mobility, and optimize oil extraction rates. We analyze different performance indicators to measure the impact of chitosan treatments on reservoir behavior and the efficiency of oil recovery.

Efficiency in Decreasing Reservoir Acidity:

The alkaline qualities of chitosan allow it to counteract the acidity of reservoirs, therefore mitigating the negative impacts of low pH on the interactions between rocks and fluids. The neutralizing procedure helps to increase permeability and improve oil displacement within reservoir formations.

Effects on Oil Extraction Rates:

Chitosan-based treatments alter the reservoir’s wetted capacity, decrease asphaltene buildup, and boost the sweeping process’ efficiency, thereby influencing the speed of oil extraction. These impacts lead to a gradual increase in oil output and improved reservoir performance.

Comparative Analysis:

We perform comparative assessments to evaluate the benefits of chitosan-based treatments against traditional acidizing procedures commonly used in oil recovery operations.

Comparison with Traditional Approaches:

Chitosan-based treatments have several benefits compared to traditional acidizing procedures, such as decreased environmental impact, increased compatibility with reservoirs, and improved safety for personnel and equipment.

Benefits and Constraints:

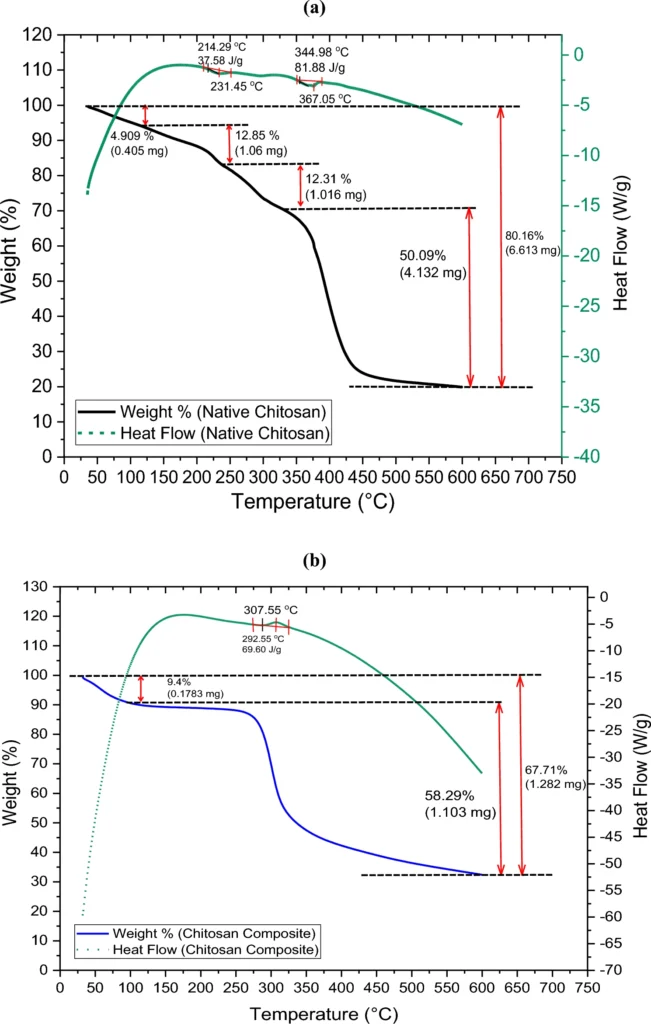

Gaining a comprehensive understanding of the benefits and constraints of chitosan composites is crucial for choosing the most effective reservoir treatment options. Consider chitosan’s suitability for specific reservoir conditions by carefully examining factors like cost-effectiveness, application flexibility, and long-term performance. TGA Analysis of (a) native and; (b) composite chitosan.

Environmental Considerations:

The environmental impact of chitosan-based treatments is a crucial concern in reservoir engineering and oil recovery operations. Chitosan’s biodegradability, low toxicity, and eco-friendly characteristics make it a viable alternative to conventional chemical treatments.

Ecological Impact of Chitosan Use:

Chitosan’s biocompatibility and biodegradability reduce ecological concerns related to reservoir treatments. Unlike synthetic compounds, chitosan breaks down naturally into non-toxic byproducts, lowering the overall environmental imprint of oil recovery processes.

Sustainability and biodegradability:

Chitosan-based treatments’ sustainability aligns with industrial ambitions to adopt green technology and reduce carbon emissions. By using natural polymers like chitosan, oil and gas businesses can strengthen their environmental stewardship while enhancing operational efficiency.

Future Prospects:

The successful assessment of modified chitosan in acidic reservoirs sets the path for future research and development initiatives targeted at enhancing its performance and broadening its applications in oil recovery.

There is potential for further research and development:

Future research directions may include exploring innovative modified chitosan formulations, finding synergies with other EOR technologies, and optimizing application procedures for varied reservoir conditions.

The implications for the oil and gas industry are significant:

The broad implementation of chitosan-based therapies could transform reservoir management methods and contribute to sustainable oil recovery technologies. The scalability and versatility of chitosan composites offer intriguing answers to industrial difficulties, increasing innovation and efficiency in oil and gas operations.

Conclusion:

In conclusion, the assessment of modified chitosan composites through pilot and field-scale simulation studies is a transformative approach to reservoir engineering. Chitosan’s unique qualities enable effective control of reservoir acidity, increase oil recovery rates, and promote environmental sustainability within the oil and gas industry. As research and development efforts continue to improve, chitosan-based treatments hold enormous potential for increasing reservoir performance and driving technological advancements in oil recovery.

FAQs:

1). Is chitosan safe for use in reservoir applications?

Chitosan is considered safe and environmentally benign, with minimal toxicity and biodegradability.

2). What are the primary benefits of utilizing modified chitosan in acidic reservoirs?

Chitosan can neutralize acidity, improve permeability, and enhance oil recovery rates.

3). How does chitosan compare to traditional acidizing techniques?

Chitosan has several advantages, including a lower environmental impact and increased safety features.

4). Is it possible to use chitosan in offshore reservoirs?

Yes, chitosan-based treatments are suitable for numerous reservoir types, including offshore situations.

5). What are the next research directions for chitosan in oil recovery?

A future study may focus on optimizing chitosan formulations, identifying synergies with other EOR approaches, and measuring long-term reservoir performance.

For more chemistry blogs, visit chemistry Master