Table of Contents

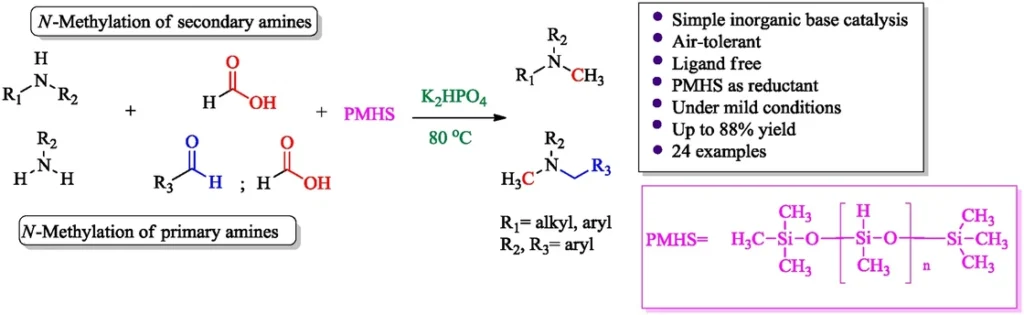

An Overview of N-Methylation of Secondary Amines:

The process of N-methylation of secondary amines is a crucial chemical reaction extensively employed in organic synthesis. The process entails introducing a methyl group (-CH3) onto the nitrogen atom of a secondary amine, leading to the creation of tertiary amines. The N-methylation process is a crucial technique in synthetic organic chemistry because tertiary amines are important intermediates in manufacturing medicines, agrochemicals, and fine chemicals.

Conventional Techniques for N-Methylation Methods Utilizing Solvents:

Solvent-Based Methods:

In the past, N-methylation processes were performed using methods that used solvents. In these approaches, secondary amines were treated with methylating agents while organic solvents were present. Typical solvents include methanol, ethanol, acetone, and chlorinated hydrocarbons like dichloromethane. Although these methods are often successful, they have several limitations, such as environmental issues, safety risks, and inefficiencies. Conventional solvent-based processes typically necessitate substantial amounts of solvent, resulting in the production of substantial waste. Moreover, the utilization of combustible or poisonous solvents presents safety hazards to operators and may require strict safety precautions and waste disposal procedures.

An overview of solvent-free ball milling:

Solvent-free ball milling has become a viable and effective substitute for conventional solvent-based techniques in organic synthesis, offering sustainability and efficiency. This novel method harnesses the mechanical energy produced by fastball collisions in a milling tank to promote chemical reactions between solid reactants, thereby removing the requirement for volatile organic solvents.

Solvent-free ball milling is a process that relies on mechanochemistry, which involves the use of mechanical forces like impact, shear, and friction to cause the breaking and creation of chemical bonds in solid-state reactions. This approach allows for the rapid and efficient synthesis of organic compounds by grinding solid reactants together without using a solvent. It also helps minimize environmental effects and improve safety.

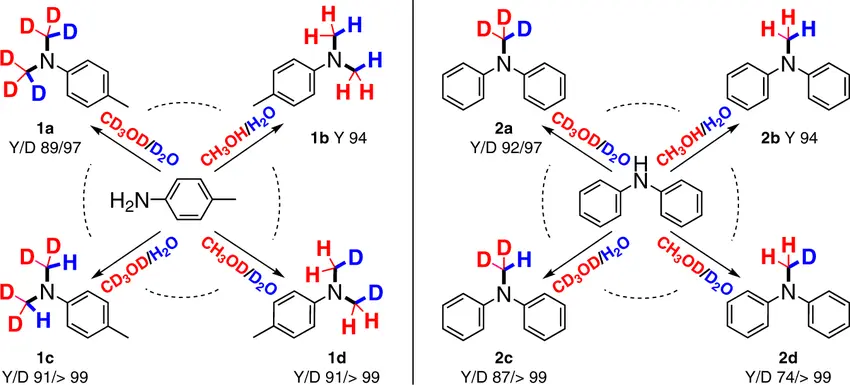

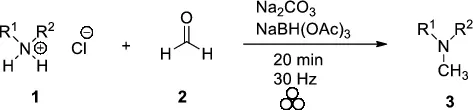

An examination of the principles and mechanisms behind solvent-free ball milling for N-methylation:

In the process of N-methylation using solvent-free ball milling, secondary amines, and methylating chemicals are mixed with solid supports or grinding media within a ball mill. The milling procedure enhances the thorough blending and interaction between the reactants, hence facilitating the transfer of methyl groups from the methylating agent to the secondary amine through collision. Eliminating the presence of a solvent medium facilitates direct interaction between the solid reactants, resulting in accelerated reaction speeds and increased product yields.

Benefits compared to conventional approaches:

Solvent-free ball milling provides numerous advantages compared to conventional solvent-based procedures for N-methylation.

Environmental sustainability: is achieved by eliminating organic solvents, which not only eliminates waste generation but also minimizes the negative influence on the environment. This approach is in line with the concepts of green chemistry and sustainable development.

Enhanced safety: The process’s lack of flammable or poisonous solvents improves its safety profile, minimizing the likelihood of fire, explosion, and exposure to dangerous chemicals.

Mechanochemical activation enhances reaction kinetics, resulting in accelerated reaction rates and improved selectivity. This enables shorter reaction times and greater overall efficiency.

Versatility about a wide range of substrates: The technique of solvent-free ball milling can be utilized for a broad spectrum of secondary amines and methylating agents, providing versatility and adaptability in synthetic applications.

Key Factors Influencing the Efficiency of N-Methylation under Ball Milling Conditions:

Factors that have a significant impact on the efficiency of N-methylation while using ball milling conditions.

Selection of reactants:

The selection of a secondary amine and methylating agent is crucial for achieving good N-methylation reactions when using ball milling settings. When choosing suitable reactants, it is important to take into account factors such as reactivity, solubility, and compatibility with the milling process.

Grinding Media:

Abrasive materials are used to reduce the size of particles in various industrial processes.

The characteristics and attributes of the grinding media employed in the ball mill can have a substantial influence on the effectiveness and result of N-methylation reactions. The particle size reduction, homogeneity of the reaction mixture, and energy transfer during milling are influenced by factors such as the material composition, size, shape, and surface area of the grinding media.

Parameters for milling:

Efficiently adjusting milling parameters, such as milling time, rotation speed, and milling vessel geometry, is crucial for obtaining the best possible outcomes in solvent-free ball milling reactions. Optimal milling conditions are carefully regulated to maximize energy input and facilitate the production of desired products while avoiding the occurrence of unwanted side reactions and the development of by-products.

Utilizations of Solvent-Free Ball Milling in N-methylation:

Solvent-free ball milling has been extensively utilized in diverse industries, including:

Pharmaceutical industry: The pharmaceutical industry focuses on the rapid and efficient production of drug intermediates, active pharmaceutical ingredients (APIs), and pharmaceutical scaffolds.

Organic synthesis: Chemical synthesis of high-quality and precise compounds: a versatile approach for synthesizing intricate organic compounds, natural products, and specialized chemicals.

Materials science: The production of functional materials, metal-organic frameworks (MOFs), and coordination polymers with customized properties.

Initiatives in the field of green chemistry: The contribution to sustainable and environmentally friendly methods of creating synthetic pathways, facilitating cleaner and more environmentally conscious chemical processes.

Analysis of specific instances or examples validating the efficiency of solvent-free ball milling:

Multiple investigations have proven the efficacy and adaptability of solvent-free ball milling for N-methylation reactions involving different substrates and applications. These case studies demonstrate the ability to scale up, replicate, and apply the ball milling method in synthetic organic chemistry.

An analysis of the differences between solvent-based methods and ball milling for N-methylation:

Solvent-free ball milling has numerous benefits compared to conventional solvent-based techniques for N-methylation, such as:

Eco-friendly synthesis involves the elimination of solvents, which effectively reduces the environmental impact and minimizes waste formation. This approach promotes sustainability and enhances resource efficiency.

Improved safety: The lack of flammable or poisonous solvents enhances operator safety and decreases the likelihood of accidents or chemical exposure.

Mechanochemical activation enhances reaction kinetics, resulting in accelerated reaction rates and improved yields when compared to traditional approaches. This leads to heightened productivity and cost-effectiveness.

Adherence to green chemistry principles: Ball milling without solvents adheres to the principles of green chemistry by reducing the use of solvents, energy consumption, and waste generation, thereby promoting the advancement of more environmentally friendly chemical processes.

Potential developments and progress in the field:

Ongoing research in the field of solvent-free ball milling for N-methylation is continuously advancing, with an emphasis on:

Research and creation of innovative milling methods: investigation of fresh milling approaches, equipment blueprints, and milling procedures to improve effectiveness, expandability, and adaptability.

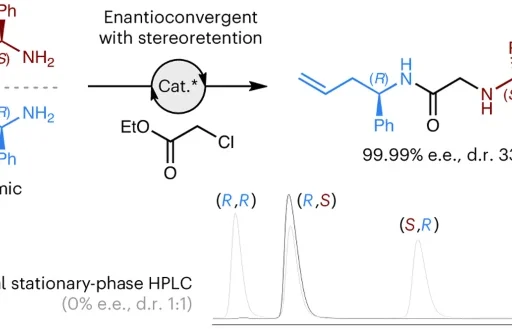

Progress in catalyst design: the incorporation of catalysts and co-catalysts to promote and regulate N-methylation reactions in the presence of ball milling conditions, hence allowing for specific and stereoselective conversions.

Utilization on intricate surfaces: An inquiry into the use of ball milling without solvents for the production of difficult substrates, heterocyclic compounds, and natural products, hence broadening the range and usefulness of this technology in organic synthesis.

Collaboration with other green chemical methodologies: The utilization of solvent-free ball milling in conjunction with other sustainable synthesis techniques, such as flow chemistry, microwave heating, and photochemistry, to create synergistic and ecologically favorable synthetic pathways.

In conclusion:

Ball milling without solvents is a convenient, efficient, and environmentally friendly method for the N-methylation of secondary amines. This new technology utilizes the mechanical energy from ball collisions to facilitate chemical reactions without the need for solvents. It offers several advantages compared to standard solvent-based procedures, such as increased safety, decreased environmental impact, and accelerated reaction kinetics. Solvent-free ball milling shows potential as a versatile tool for sustainable organic synthesis and green chemistry, with ongoing improvements and applications in diverse sectors.

Frequently Asked Questions:

1). What are the benefits of using solvent-free ball milling for N-methylation?

Ball milling without solvents has benefits such as less environmental impact, heightened safety, accelerated reaction rates, and adherence to green chemistry principles in contrast to conventional solvent-based techniques.

2). Does solvent-free ball milling work for all secondary amines?

The technique of solvent-free ball milling is suitable for a broad spectrum of secondary amines. However, the selection of reactants and milling conditions may differ based on the particular substrates and reaction specifications.

3). What is the role of solvent-free ball milling in promoting green chemistry?

The utilization of solvent-free ball milling in chemical synthesis enhances sustainability by eliminating the requirement for organic solvents, lowering the formation of waste, limiting energy consumption, and improving safety.

4). Are there any safety considerations related to solvent-free ball milling?

The use of solvent-free ball milling is often seen as a safer alternative to solvent-based procedures because it eliminates the presence of flammable or hazardous solvents. Nevertheless, it is crucial to handle equipment correctly and strictly follow safety rules to reduce hazards and guarantee the safety of the operator.

5). Is it possible to expand the use of solvent-free ball milling for industrial purposes?

The scalability and practicality of solvent-free ball milling have been proven for industrial applications, providing potential advantages in terms of cost-effectiveness, process intensification, and environmental sustainability.

For more chemistry blogs, visit chemistry Master