Table of Contents

Overview:

Nylon-6, a man-made polymer extensively used in textiles, automotive components, and other consumer products, has emerged as a notable environmental issue due to its long-lasting presence in the environment and difficulties in the recycling process. Conventional chemical recycling techniques need a lot of energy and are frequently ineffective, which has sparked a rising interest in alternative ways.

The enzymatic depolymerization of nylon-6 provides a hopeful answer by disintegrating the polymer into its constituent monomers under gentle conditions, allowing for more environmentally friendly recycling methods. This article talks about the important steps in searching through natural varieties to find the right enzymes, making tests to see how active they are, and studying these enzymes to make the depolymerization process better. Nylonase activity is found across enzymes with different active site architectures and diverse substrate preferences.

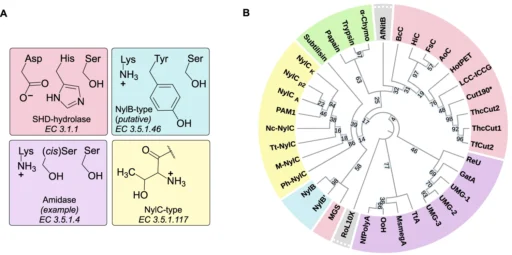

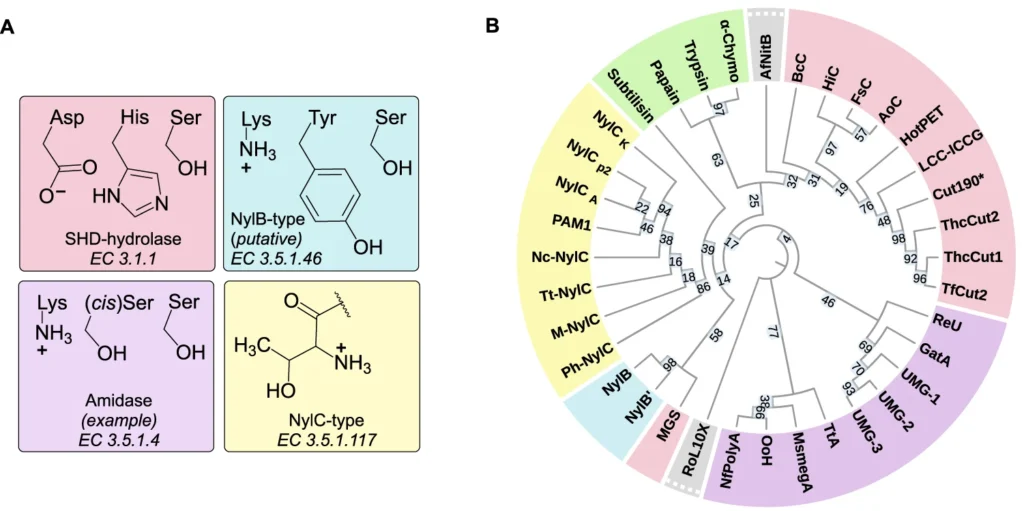

photo credit A Example catalytic residues used by potential nylonases: Ser-His-Asp (SHD) serine hydrolases, NylB-type serine hydrolases (putative catalytic triad for this enzyme group, only two known enzymes described), amidases (example amidase catalytic triad used by Ser-(cis)Ser-Lys amidases), and NylC-type N-terminal nucleophile hydrolases. B Phylogenetic tree of enzymes selected for potential PA6 deconstruction activity, colored to match the enzyme groupings used throughout (yellow: NylC-type, blue: NylB-type, purple: amidase, pink: SHD-hydrolase, green: protease, gray: misc.).

Inset numbers on the branches represent confidence values (%). References for the enzyme source and group are available in Supplementary Data 1, enzyme sequences, EC numbers, and expression conditions are available in Supplementary Data 2. α-Chymo α-Chymotrypsin, HotPET HotPETase, MGS MGS0156, UMG-1 UMG-SP-1, UMG-2 UMG-SP-2, UMG-3 UMG-SP-3.

Comprehension Nylon-6 is a type of synthetic polymer:

Nylon-6, or polycaprolactam, is a polyamide frequently utilized in the production of fabrics, carpets, and industrial components. The chemical structure consists of a recurring caprolactam unit connected by amide bonds. People highly value Nylon-6 for its robustness, flexibility, and durability, making it a flexible substance suitable for various uses.

Nevertheless, these specific characteristics also add to its ecological footprint. Nylon-6 is non-biodegradable, resulting in its accumulation in landfills and natural habitats. The challenge of recycling nylon-6 stems from the need to break the resilient amide bonds, a task that necessitates the use of harsh chemical methods that are neither economically nor environmentally sustainable.

The concept of enzymatic depolymerization refers to the process of breaking down large molecules into smaller units using enzymes:

Enzymatic depolymerization is a process in which enzymes catalyze the decomposition of polymers into their monomers. This procedure takes place in moderate settings, such as room temperature and neutral pH, making it a more environmentally friendly option compared to chemical depolymerization. Chemical depolymerization frequently involves high temperatures, pressures, and hazardous solvents.

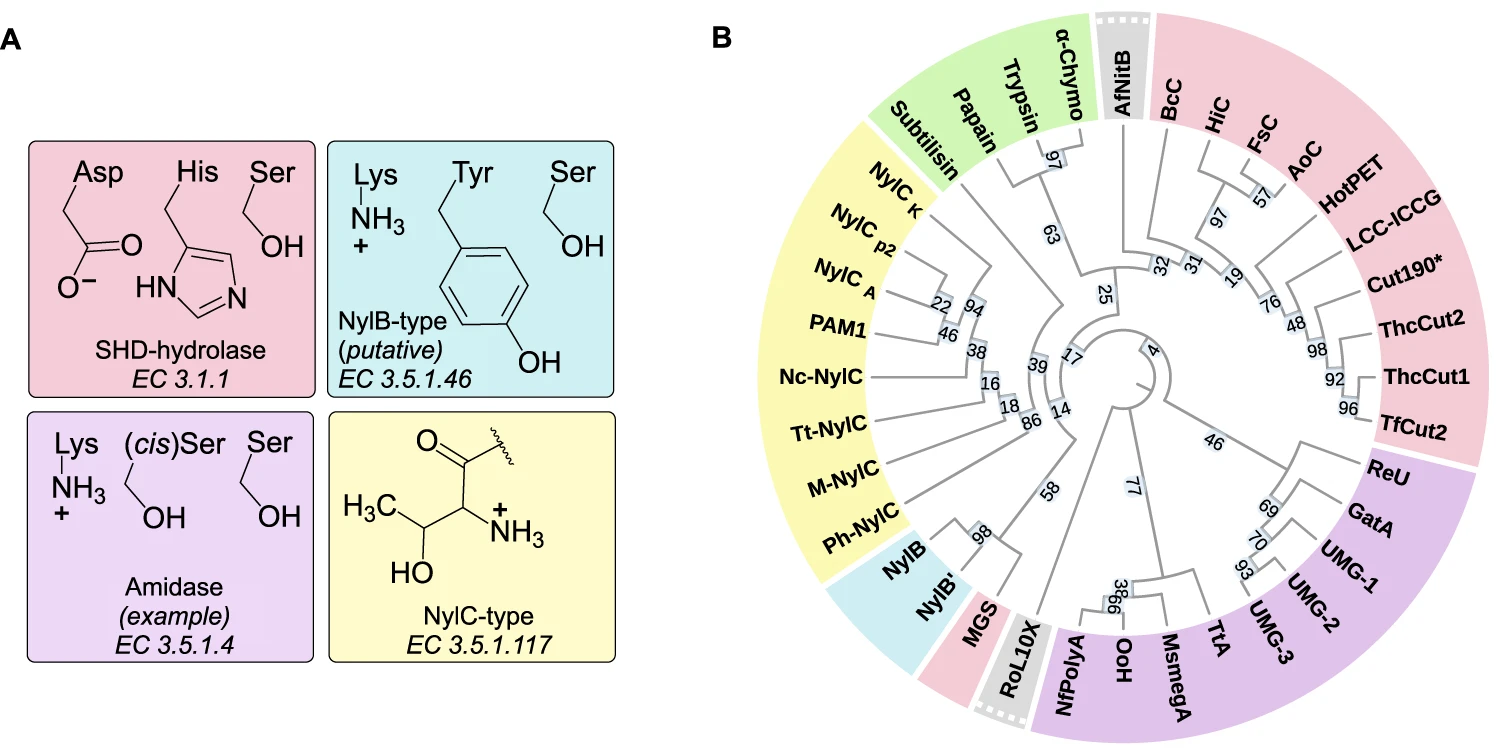

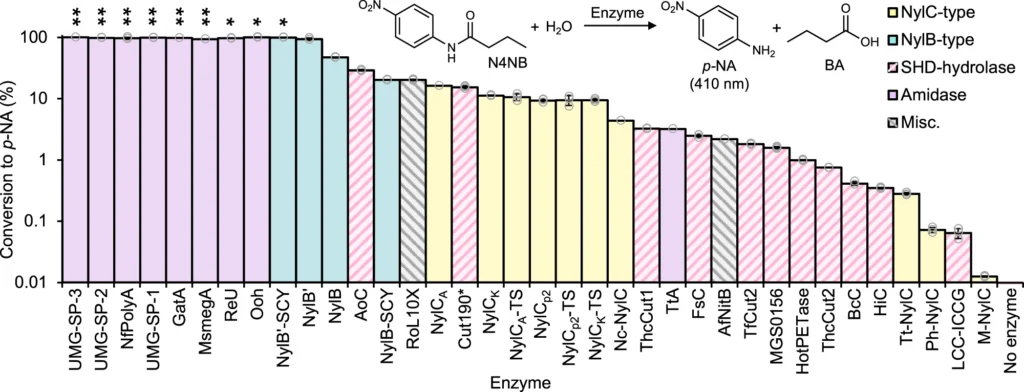

In the case of nylon-6, enzymatic depolymerization breaks down the polymer into caprolactam. This caprolactam can then be cleaned up and reused to make new nylon-6 products. The primary benefit of this approach is its ability to be precise and effective, enabling the selective decomposition of nylon-6 without producing any harmful secondary substances. N-(4-nitrophenyl)butanamide (N4NB) activity assays with potential nylonases.

An Introduction to Natural Diversity Screening:

Researchers use natural variety screening to find new enzymes from a variety of biological sources, including bacteria, plants, and animals. This strategy uses a wide range of life forms and their distinct metabolic pathways to uncover enzymes that conventional laboratory techniques may not be able to detect.

The significance of natural diversity screening lies in its ability to reveal enzymes with unique or improved capabilities, particularly for industrial processes such as nylon-6 depolymerization. Researchers can utilize the genetic diversity present in the natural world to discover enzymes that have evolved to break down comparable substances. Researchers can modify these enzymes to facilitate the depolymerization of nylon-6.

The techniques for evaluating enzymes for the breakdown of Nylon-6 are discussed:

Typically, the process of identifying enzymes that may break down nylon-6 starts with selecting prospective sources. Microorganisms found in environments rich in nylon-6 or related polymers are excellent candidates, as they may have evolved enzymes capable of breaking down these substances. Metagenomic libraries, which consist of genetic material from various contexts, are highly useful resources that provide access to a wider array of enzyme activity.

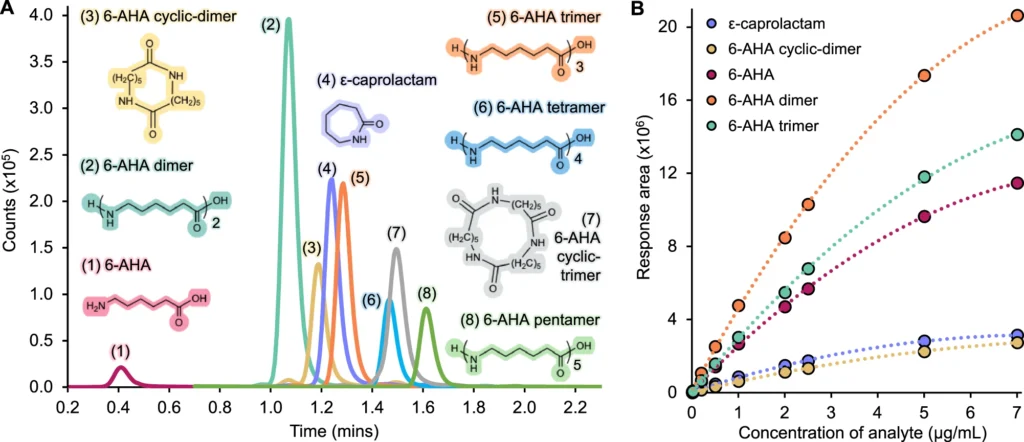

We use high-throughput screening techniques to quickly evaluate the degradation capabilities of several enzymes or enzyme variations against nylon-6. These methods frequently employ automated systems that can concurrently assess numerous variables, such as temperature and pH, to discover the most favorable enzyme candidates. LC-MS/MS analysis of major soluble compounds present in enzymatic PA6 deconstruction reactions.

Enzymatic Activity Assay Development:

Assay creation is an essential and crucial stage in the screening process, as it enables the measurement of enzyme activity specifically against nylon-6. We formulate efficient assays to possess sensitivity, reproducibility, and the ability to differentiate between various degrees of activity.

Many tests are used in this situation, including colorimetric tests that show a color change when enzymes are present and chromatographic tests that separate and measure the byproducts of nylon-6 breakdown. The selection of an assay is contingent upon the specific demands of the screening procedure, such as the need for live monitoring or the ability to manage a large quantity of samples.

Analysis of Depolymerisation Enzymes:

After screening for possible enzymes, it is necessary to characterize them to assess their suitability for industrial uses. Characterization entails evaluating multiple attributes of the enzyme, including its performance under diverse circumstances, durability, and selectivity towards substrates.

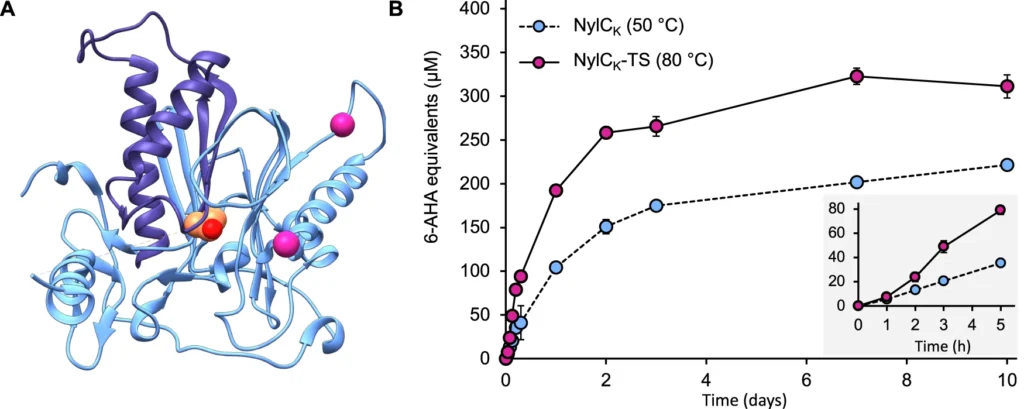

We commonly employ activity tests to quantify the enzymatic depolymerization rate of nylon-6 under various pH, temperature, and substrate concentration conditions. Stability tests are required to determine the duration of enzyme activity in operational settings, which is critical for the process’s scalability. Also, substrate specificity experiments can show if the enzyme only reacts with nylon-6 or if it also speeds up reactions with other polymers, which could make it less useful in industrial settings. Comparison of NylCK and the thermostabilized variant NylCK-TS.

Enhancing the Efficiency of Enzymatic Depolymerisation:

Optimizing the depolymerization process entails increasing the enzyme’s efficiency and selectivity. We frequently employ protein engineering techniques like directed evolution and site-directed mutagenesis to enhance enzyme activity. These techniques entail introducing genetic mutations into the enzyme’s DNA sequence and then choosing the variations that exhibit enhanced performance.

Experimental studies have shown that small changes in the order of an enzyme’s amino acids can greatly improve its ability to break down nylon-6, making it more useful for industrial purposes. In addition, fine-tuning the reaction parameters, such as modifying pH, temperature, and enzyme concentration, can further improve the depolymerization process.

There are difficulties in the enzymatic depolymerization of nylon-6:

Despite the great potential of enzymatic depolymerization, there are still some obstacles that require attention. A significant challenge lies in the identification of enzymes that exhibit both high efficiency and stability in industrial settings. Numerous naturally occurring enzymes experience rapid degradation or a decline in activity when exposed to the elevated temperatures commonly necessary in industrial operations.

The economic viability of enzymatic depolymerization is another obstacle. Although the technique is ecologically superior to chemical procedures, it may incur higher costs due to the expenses associated with enzyme manufacturing and the comparatively slower reaction rates. To tackle these issues, continuous research and development are necessary to enhance enzyme efficiency and lower expenses.

Uses of Nylon-6 Depolymerisation:

The effective depolymerization of nylon-6 has profound ramifications for sectors that are dependent on this material. Recycling presents a significant opportunity, as the depolymerization of nylon-6 can facilitate the production of new goods through polymerization. This helps to decrease the demand for new materials and minimise waste.

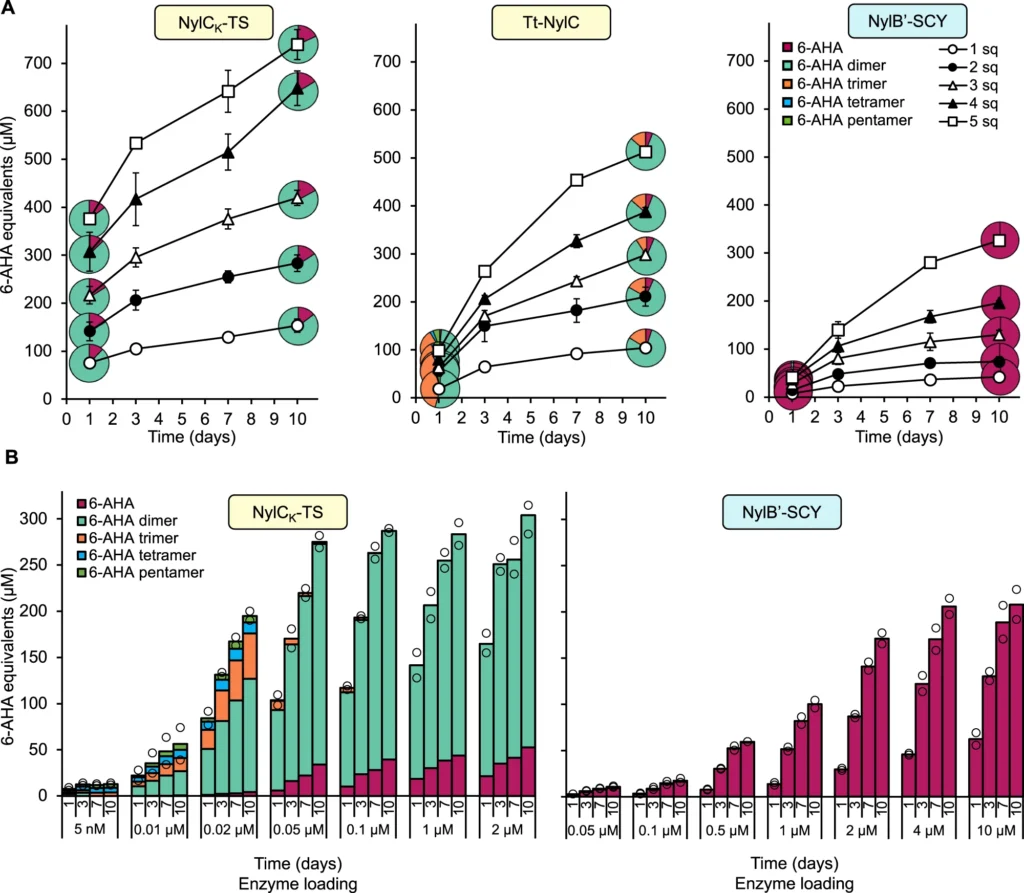

Enzymatic depolymerization, with recycling, has the potential to be a vital component of waste management. It offers a sustainable approach to breaking down nylon-6 in landfills or polluted areas. This aligns with broader circular economy initiatives, aiming to create closed-loop systems that consistently reuse materials rather than discard them. Exploration of reaction conditions for enzymatic PA6 depolymerization.

Long-term viability and ecological consequences:

The environmental advantages of enzymatic depolymerization are evident. This strategy has the potential to significantly reduce plastic pollution by providing a way to recycle nylon-6 without the harmful byproducts often produced by chemical methods. Furthermore, the reduced energy requirements and less severe circumstances of enzymatic depolymerization contribute to a lower environmental impact, thereby improving its sustainability credentials.

When comparing the environmental impact of enzymatic depolymerization with chemical approaches, it is evident that enzymatic depolymerization results in a substantial decrease in toxic emissions and energy consumption. Therefore, enzymatic depolymerization is a more sustainable option for handling nylon-6 waste. Businesses that use nylon-6 could have a much smaller negative effect on the environment if enzymatic depolymerization was added to the current waste management systems.

The analysis focuses on specific instances and recent progress:

Recent advancements in the field have demonstrated the successful large-scale implementation of enzymatic depolymerization in industrial environments. Researchers have effectively manipulated enzymes to increase their effectiveness against nylon-6, resulting in accelerated and more thorough depolymerization. These advancements are creating opportunities for commercial utilization, as multiple organizations are investigating the incorporation of these enzymes into their recycling procedures.

Prominent case studies include the development of recycling facilities that use enzymes to treat nylon-6 waste more efficiently than conventional techniques. These facilities are indicative of the increasing popularity of bio-based methods for managing plastic trash. They demonstrate the potential of enzymatic depolymerization to revolutionize the sector.

Prospects for the Future:

In order to progress, the future of nylon-6 depolymerization relies on ongoing innovation and collaboration across various fields of study. We anticipate that advancements in synthetic biology, bioinformatics, and materials science will play a pivotal role in tackling current challenges and uncovering new avenues for enzyme-based recycling

Recently, new discoveries show that combining enzymatic depolymerization with other eco-friendly technologies, like biodegradable plastics and bio-based production methods, might be able to provide complete ways to deal with polymer waste. The potential for multidisciplinary research is extensive, and in the coming years, there may be notable advancements in the creation of enzymes that are more efficient and affordable for breaking down nylon-6.

In conclusion:

The enzymatic breakdown of nylon-6 shows enormous potential as an environmentally friendly approach to managing trash, providing a more sustainable option compared to conventional chemical techniques. Researchers are using natural diversity screening, assay development, and enzyme characterization to discover novel methods for degrading this persistent polymer. These findings have important implications for recycling and environmental conservation. The ongoing development of enzymatic depolymerization holds tremendous potential to contribute to a circular economy and mitigate plastic pollution.

Frequently Asked Questions:

1). Nylon-6 is a synthetic polymer that is of concern due to its negative impact on the environment.

Multiple sectors extensively use Nylon-6, a synthetic polymer. Because it is non-biodegradable, it accumulates in landfills and natural ecosystems, causing pollution.

2). What are the differences between enzymatic depolymerization and chemical methods?

Enzymatic depolymerization employs enzymes to dismantle polymers in gentle settings, while chemical approaches typically necessitate elevated temperatures, pressures, and hazardous solvents.

3). What are the primary obstacles encountered in the development of enzymes for the process of nylon-6 depolymerization?

Challenges encompass the identification of enzymes that exhibit high efficiency, stability in industrial settings, and economic feasibility for large-scale implementation.

4). Is it possible to repurpose or recycle depolymerized nylon-6?

Indeed, purifying depolymerized nylon-6 and using it to produce fresh nylon-6 items can improve the sustainability of the recycling process.

5). What are the future possibilities for enzymatic depolymerization technologies?

The future appears auspicious, since advancements in enzyme engineering, synthetic biology, and interdisciplinary research are expected to improve the effectiveness and acceptance of enzymatic depolymerization.

For more chemistry blogs, visit chemistry Master