Table of Contents

The field of oil well cementing has embraced geopolymer cement due to its crucial role in ensuring well integrity and performance. Advances in material science have made this type of cement, known for its high density and durability, possible. Perlite in Geopolymer cement provides several benefits compared to conventional Portland cement, such as enhanced strength, durability, and resilience to challenging downhole environments. However, a persistent challenge in the development of high-density geopolymer cement is the control of sedimentation during the cementing process.

An overview of Perlite’s role in Geopolymer Cement:

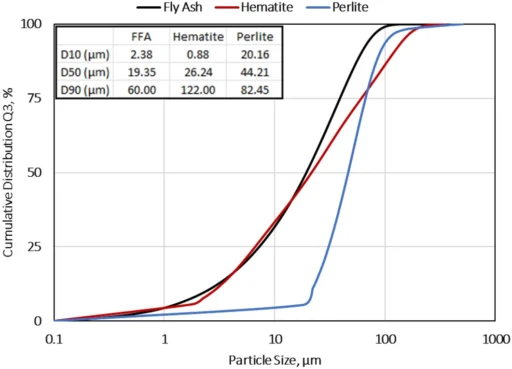

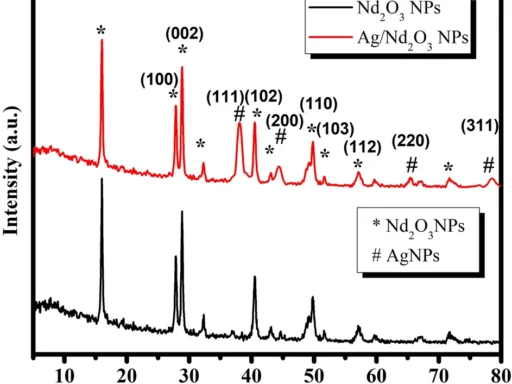

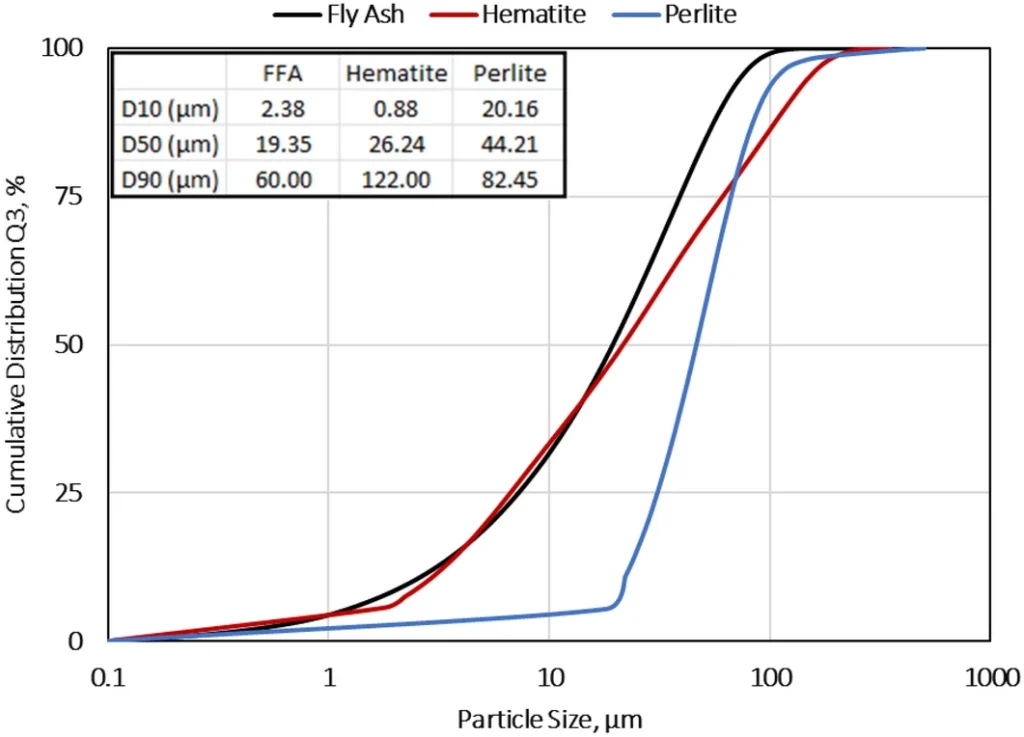

Perlite, a naturally occurring volcanic glass rich in silica, has shown great potential as an addition in geopolymer cement formulations. Because of its lightweight and porous characteristics, it is well-suited for improving the qualities of geopolymer cement used in oil well operations. Perlite in Geopolymer cement benefits significantly, as it undergoes a chemical reaction with alkaline activators when combined with aluminosilicate minerals. The PSD results of FFA, hematite, and perlite.

Issues with Oil Well Cementing:

Oil well cementing necessitates the use of cement compositions that possess the ability to endure elevated pressures, temperatures, and corrosive surroundings. The settling of dense particles in the cement slurry is a crucial concern, as it has the potential to undermine the quality of the cement and the integrity of the well. Furthermore, the task of attaining high-density cement while maintaining other desirable characteristics is a substantial technological obstacle.

The role of perlite in geopolymer cement is significant:

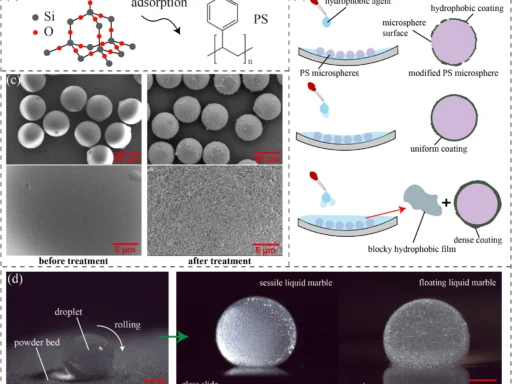

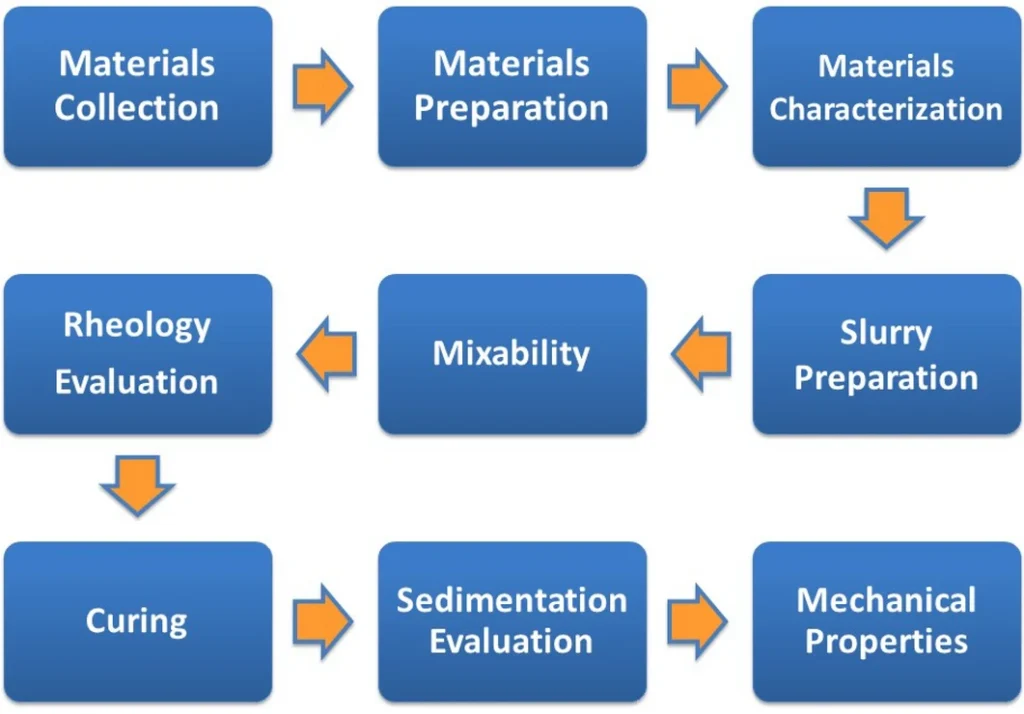

Perlite is a versatile component in geopolymer cement, effectively addressing several significant issues encountered in the oil well cementing process. The addition of perlite slows down the settling of heavier components, leading to a more uniform and stable cement slurry. In addition, perlite helps regulate the density of the cement while improving its mechanical characteristics. The overview of the steps followed in this work.

Enhancements in Cement Characteristics:

Perlite incorporation into geopolymer cement yields significant enhancements in multiple cement characteristics. Perlite helps to improve the cement matrix’s compressive and flexural strengths. Furthermore, it helps to regulate the cement’s compactness, allowing for customized compositions that are appropriate for various wellbore conditions. Finally, the permeable composition of perlite offers thermal insulation advantages, diminishing the dissipation of heat in deep wells.

Empirical research and results of Perlite in Geopolymer Cement:

Several research papers have examined the impact of adding perlite in geopolymer cement on its characteristics. Evidence from real life keeps showing that adding perlite in geopolymer cement lowers the rate of sedimentation, raises the mechanical strength, and makes the density characteristics better. These investigations have established the foundation for the actual implementation of perlite-based geopolymer cement in oil well cementing operations.

Utilization in Oil Well Cementing:

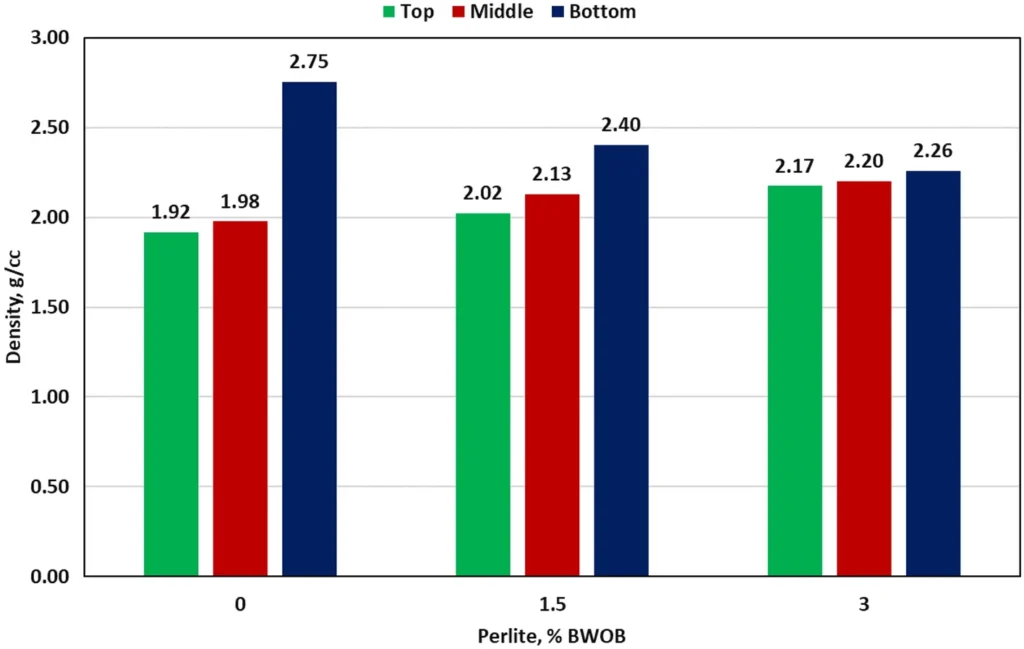

Perlite in geopolymer cement is used in oil well cementing, which has tangible benefits. It allows for the creation of cement mixtures with a high concentration of particles, which have excellent physical characteristics and can withstand challenging underground conditions. The results of field tests have been positive, showing that using perlite-enhanced cement is a good way to ensure zonal isolation and wellbore integrity. API method results for different perlite concentrations.

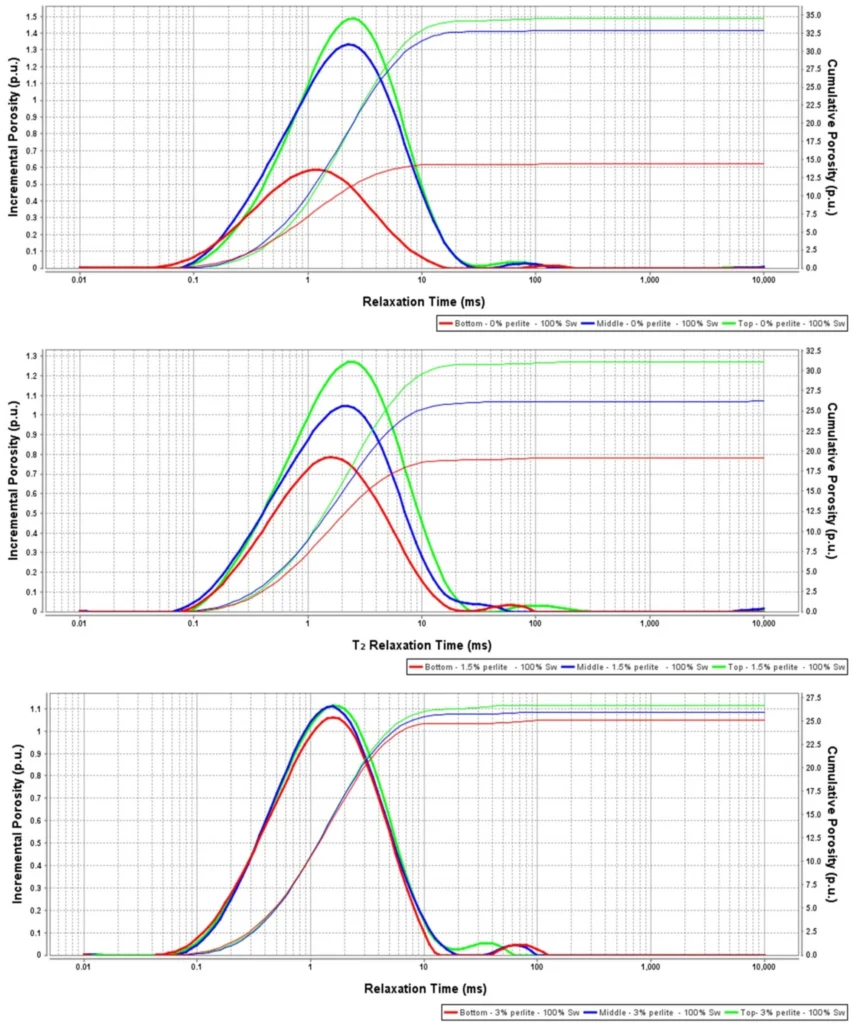

Graphically Representation: NMR results for the 3 perlite percentages used in this study [0% (a), 1.5% (b) and 3% (c)].

We must consider environmental and economic factors:

From an environmental perspective, geopolymer cement with perlite offers a more sustainable option compared to traditional cement in terms of its lower carbon emissions and energy usage in the manufacturing process. Furthermore, the economic viability of perlite-based geopolymer cement is garnering attention as it offers cost-effective solutions for oil and gas companies seeking durable and high-performing cementing solutions.

Future Opportunities and Innovations:

Future research and development endeavors will focus on enhancing the efficiency of incorporating perlite in geopolymer cement formulations. We anticipate that advancements in material science and cementing technology will accelerate the development of high-density cement systems for oil well applications. The ongoing collaboration among academia, industry, and technology providers will result in the creation of advanced cementing solutions for the future.

In conclusion:

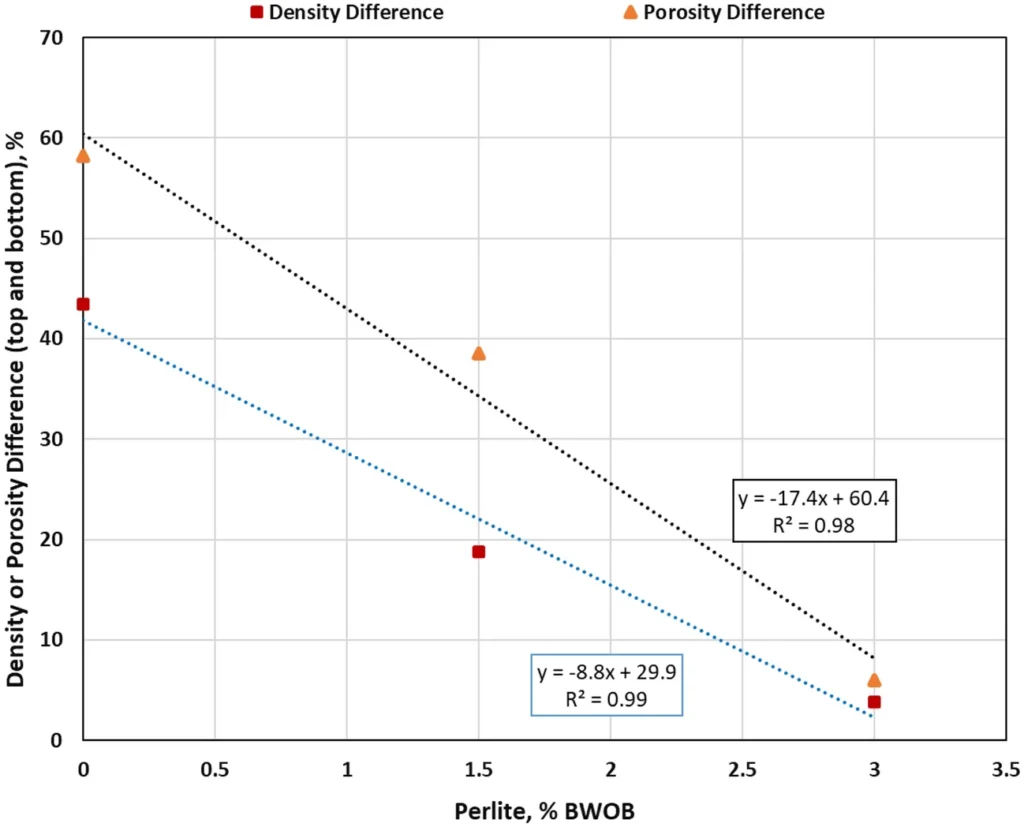

The inclusion of perlite in geopolymer cement is a notable step towards addressing sedimentation issues and improving the characteristics of dense cement used for oil well cementing. Perlite has synergistic effects that enhance slurry stability, mechanical strength, and density control. This makes cementing operations in the oil and gas industry more efficient and sustainable. Density and porosity differences between top and bottom sections for different perlite concentrations.

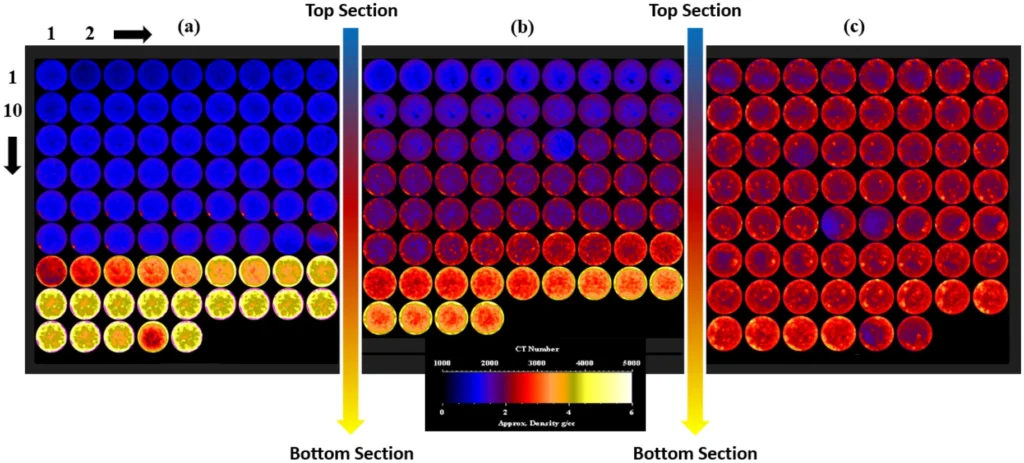

CT-scan results for different perlite concentrations [0% (a), 1.5% (b), and 3% (c)].

Frequently Asked Questions:

1). What role does perlite play in improving the properties of geopolymer cement?

Perlite functions as an ingredient in geopolymer cement compositions to decrease sedimentation, improve mechanical strength, and optimize density.

2). What effect does adding perlite have on the sedimentation process in high-density cement?

Perlite decreases the speed at which sediment settles, leading to cement slurries that are more consistent and uniform, making them acceptable for cementing oil wells.

3). Is geopolymer cement with perlite more cost-effective than traditional cement?

Geopolymer cement with perlite provides economic advantages due to its long-lasting nature, minimized ecological footprint, and customizable characteristics.

4). What are the ecological advantages of including perlite in cement production?

Perlite-based geopolymer cement has a reduced carbon footprint and energy usage in comparison to traditional Portland cement.

5). What role do geopolymer cement and perlite play in promoting sustainable oil well operations?

Perlite-based geopolymer cement facilitates sustainable practices in oil and gas exploration and production by offering long-lasting and high-performing cementing solutions.

For more chemistry blogs, visit chemistry Master