Table of Contents

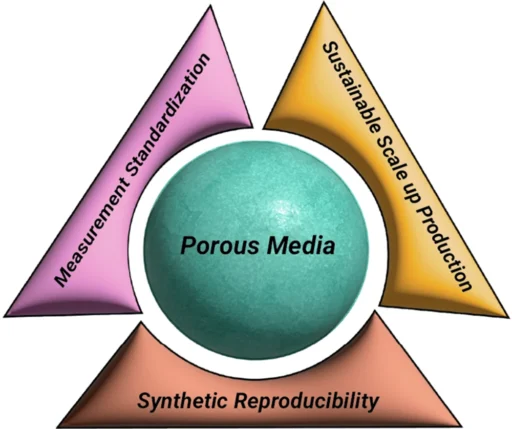

Opening statement:

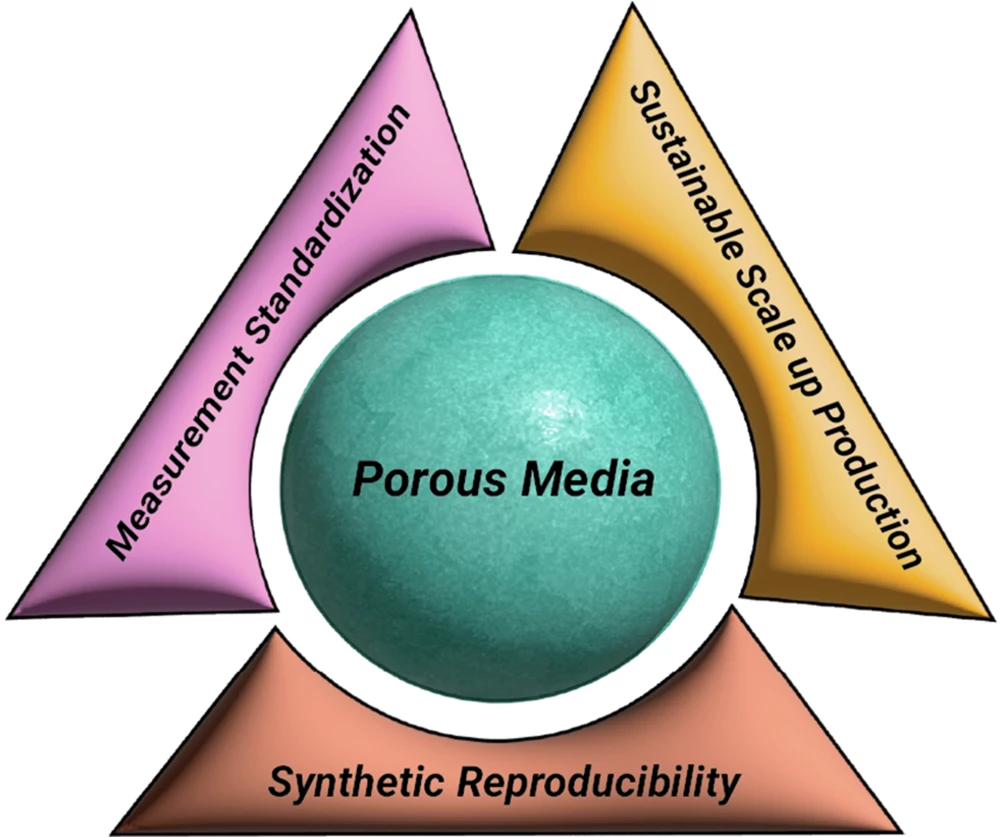

Porous materials, characterized by their distinctive structures and extensive surface areas, have garnered the interest of both scientists and enterprises. These materials are crucial in a wide range of advanced applications, including catalysis, gas storage, medication delivery, and environmental cleanup. However, achieving the full potential of porous materials requires a shift from small-scale laboratory synthesis to large-scale industrial manufacturing. This transformation, while showing potential, is filled with various obstacles that require meticulous deliberation. This article will explore the difficulties encountered in the growth of porous materials and the creative approaches developed to overcome them.

An Exploration into Porous Materials:

Before delving into the difficulties of expanding in size, it is critical to understand the nature of porous materials. These materials contain pores, which are minuscule openings or empty spaces distributed throughout their structure. The size of these pores can vary, resulting in different classifications based on their size: microporous (pores smaller than 2 nanometres), mesoporous (pores ranging from 2 to 50 nanometres), and macroporous (pores larger than 50 nanometres).

The expansive surface area and adjustable characteristics of porous materials make them highly valued for a wide range of applications. Catalysis commonly uses zeolites due to their discerning adsorption characteristics, while gas storage and separation purposes employ metal-organic frameworks (MOFs). Aerogels, a distinct category of porous substances, are renowned for their exceptional ability to insulate against heat.

There is a need for expansion:

Porous materials have many potential uses, but to satisfy industrial requirements, they must be manufactured in sufficient quantities. Scaling up offers advantages such as decreased costs, improved availability, and the capacity to meet the demand for commercial applications. Nevertheless, the process of transitioning from small-scale laboratory synthesis to large-scale industrial manufacturing is not simple. We must overcome numerous obstacles in this procedure to maintain the material’s qualities and ensure its economic viability.

During the scale-up process, one of the challenges is ensuring material consistency:

A key obstacle to expanding porous materials is ensuring their properties are uniform. In a laboratory setting, controlling the synthesis process allows for simpler regulation of pore size and distribution, resulting in uniformity. However, expanding the process could make managing these parameters more challenging, leading to fluctuations in the material’s performance. This inconsistency can have a substantial impact on the efficacy of the material in its intended use.

Production expenses:

Porous material manufacturing frequently incurs significant costs, particularly when using expensive raw ingredients and energy-intensive procedures. Expanding these processes can magnify these expenses, rendering it challenging to manufacture the materials cost-effectively. Furthermore, the need for specialized equipment and rigorous quality control techniques can increase costs.

Optimization of processes:

To increase the size or scale of a process, it is necessary to optimize different factors that affect the synthesis, such as temperature, pressure, and reaction time. Nevertheless, strategies that are effective on a small scale may not necessarily be successful when applied to bigger scales. For instance, scaling up might alter the behavior of reaction kinetics and thermodynamics, leading to less-than-optimal results. Ensuring the optimal equilibrium among these variables is essential for achieving successful expansion.

Quality Assurance:

Ensuring a steady level of quality poses a notable difficulty in the context of extensive manufacturing. Minor imperfections that may be inconsequential on a small scale in the laboratory might escalate into substantial problems when manufacturing materials in large quantities. Therefore, it is necessary to create sophisticated analytical methods and strict quality control procedures to guarantee that every batch fulfills the necessary criteria.

Ecological Consequences:

We cannot ignore the ecological consequences of extensive manufacturing. Porous material production can lead to significant waste generation and high energy consumption. With the shift towards sustainable practices in sectors, there is an increasing demand to create ecologically benign production techniques, aiming to minimize waste and decrease energy use.

Regulatory and safety concerns:

Expanding in size also presents difficulties related to regulations and safety. Industrial manufacturing entails managing large quantities of perilous substances, increasing the likelihood of accidents. Moreover, the result must adhere to several industry norms and laws, which further complicates the process of scaling up.

Strategies for addressing scale-up challenges Cutting-edge Manufacturing Methods:

Modern order to address the difficulties associated with maintaining material consistency, it is possible to utilise modern production techniques such as automation and process control technology. These approaches enable accurate manipulation of synthesis conditions, guaranteeing consistency in both pore size and distribution. Additive manufacturing, also referred to as 3D printing, is a highly promising method for producing porous materials with intricate structures on a large scale.

Efficient and economical production techniques:

Minimizing manufacturing expenses is critical for the widespread acceptance of porous materials. Utilizing alternative raw materials that are more cost-effective and easily accessible can accomplish this. In addition, the use of energy-efficient synthesis techniques, such as microwave-assisted synthesis and sol-gel procedures, can significantly reduce energy usage, thereby improving the viability of large-scale manufacturing.

Strategies for optimizing processes:

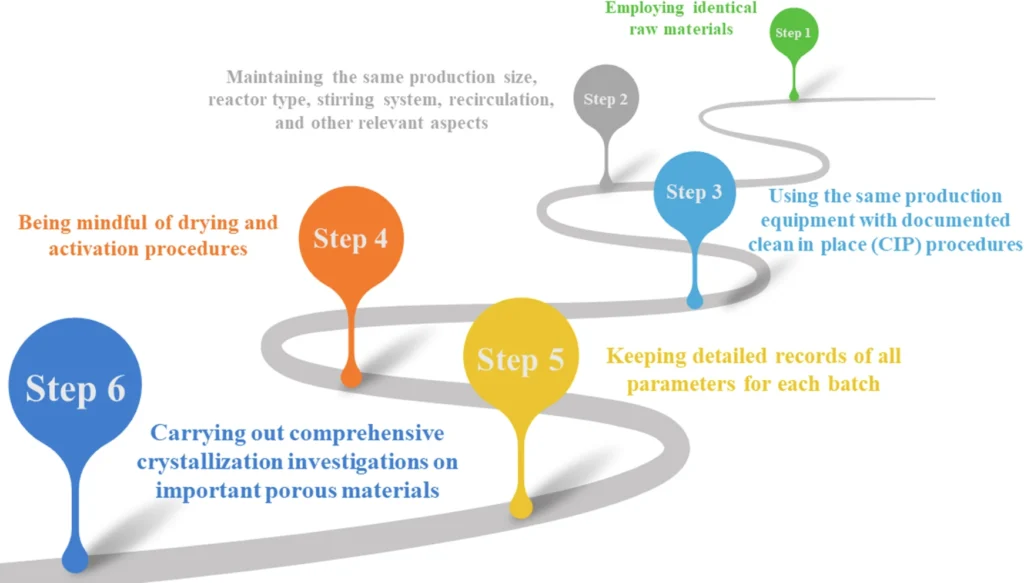

Efficiently improving the synthesis process is crucial for achieving effective scale-up. Real-time monitoring and in-situ analysis enable prompt modifications to the process parameters. Manufacturers can be sure that the larger-scale process will work the same way as the lab-scale synthesis by closely watching the reaction environment. This will keep the desired material properties.

Enhanced Quality Control Protocols:

Utilizing new analytical techniques can improve quality control in large-scale production. We can employ methods such as X-ray diffraction (XRD), gas adsorption analysis, and electron microscopy to observe and assess the structural integrity and pore properties of the materials. Using statistical process control (SPC) can also help to preserve uniformity during large batches.

Efforts to promote sustainability:

Porous material manufacturing is increasingly focused on sustainability. To tackle this issue, manufacturers are actively investigating recycling and waste minimization methods. For instance, manufacturers can reclaim and reuse the solvents used in the synthesis procedure, thereby reducing the overall environmental impact. To improve the sustainability of porous material production, efforts are underway to develop green synthesis methods that use environmentally friendly chemicals and procedures.

It is important to adhere to regulations and implement safety protocols:

Ensuring adherence to regulations and maintaining safety is of utmost importance in the context of large-scale production. This entails following established guidelines for managing dangerous substances and enforcing safety procedures to avoid accidents. Manufacturers must also remain current with international standards and laws to guarantee that their products comply with all essential requirements.

Examining Successful Scale-Up Case Studies Scaling Up:

Zeolite Catalysis in the Petrochemical Industry:

The petrochemical sector has effectively expanded the use of zeolites for fluid catalytic cracking (FCC) procedures. Many zeolites have been made on a large scale without affecting their catalytic performance. This has been possible by improving the conditions for synthesis and using advanced manufacturing techniques.

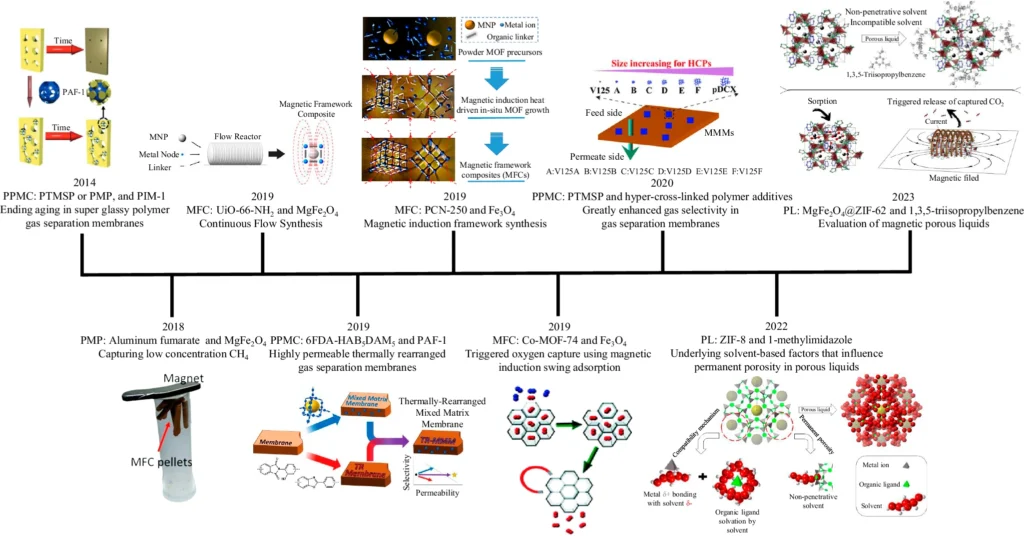

We use metal-organic frameworks (MOFs) to store and separate gases:

We have effectively expanded the size of Metal-organic frameworks (MOFs), renowned for their outstanding ability to store and separate gases. An exemplary example is the production of MOFs for carbon capture applications. Manufacturers have successfully produced MOFs on a large scale without sacrificing their performance by using cost-effective production methods and strict quality control.

Application of Aerogels in Thermal Insulation:

Many applications, including building insulation and aerospace, have successfully expanded the use of aerogels, known for their exceptional thermal insulation qualities. We have successfully produced aerogels on a wide scale using novel synthesis methods and modern manufacturing techniques, thereby increasing their availability for commercial applications. A path towards improving reproducibility.

Prospects for Expanding the Size of Porous Materials:

As we look ahead, upcoming technologies and breakthroughs have the potential to further enhance the expansion of porous materials. Integrating AI and machine learning into the production process can improve the optimization of synthesis conditions and allow for early detection of future issues. In addition, it is imperative to have joint endeavors between academia and industry to foster innovation and address the obstacles related to scaling up.

In conclusion:

Transitioning porous materials from laboratory-scale to industrial-scale production is a multifaceted undertaking that entails various obstacles. Nonetheless, it is possible to overcome these problems by using advanced manufacturing processes, implementing cost-effective production procedures, and improving quality control systems. Overcoming these obstacles can unlock the full potential of porous materials, leading to their widespread use across various industries.

Frequently Asked Questions:

1). What are porous materials and why are they important?

Porous materials are substances with small holes or spaces that allow liquids or gases to pass through. They are essential because their unique structure and properties make them useful in various applications, such as filtration, absorption, and catalysis.

Porous materials are substances that have minuscule apertures or cavities dispersed throughout their structure, resulting in a significant increase in their surface area. They are significant because of their unique characteristics, such as their exceptional ability to adsorb substances, making them valuable in various fields such as catalysis, gas storage, and medication administration.

2). What are the primary obstacles to expanding the production of porous materials?

The primary obstacles encompass upholding material uniformity, managing manufacturing expenses, enhancing the synthesis procedure, guaranteeing quality assurance, mitigating environmental repercussions, and adhering to regulatory and safety protocols.

3). What role does process optimization play in expanding porous materials?

Process optimization entails the meticulous adjustment of synthesis conditions to uphold desirable material qualities on a larger scale. Real-time monitoring, on-site analysis, and innovative manufacturing procedures can accomplish this.

4). What is the significance of sustainability in expanding porous materials?

Sustainability is of utmost importance in the context of large-scale production, as it entails the imperative of minimizing waste, decreasing energy usage, and employing ecologically friendly materials and methods. To do this, it is beneficial to employ green synthesis methods and recycling procedures.

5). Can you provide instances of effective expansion in porous materials?

In the petrochemical sector, examples include the expansion of zeolites for catalytic purposes, the use of MOFs for gas storage and separation, and the application of aerogels for thermal insulation. We have achieved these achievements by optimizing processes, implementing cost-effective production methods, and utilizing sophisticated manufacturing technology.

For more chemistry blogs, visit chemistry Master