Table of Contents

Overview of Recycling of Waste Plastics:

The escalating issue of plastic trash represents one of the most urgent environmental challenges confronting us today. Every year, landfills and oceans receive millions of tonnes of plastic, endangering ecosystems and human health. Recycling has consistently been the primary answer to this problem; nevertheless, conventional Recycling of Waste Plastics processes possess inherent limits. This is where novel methodologies, such as microwave chemical recycling, are applicable. This technology employs continuous process design and microwave-absorbing heating components to provide an innovative answer to the global plastic waste challenge.

What does it mean to recycle microwave chemicals?

Chemical Recycling of Waste Plastics entails deconstructing polymers at the molecular level and reverting them to their original monomers or other useful compounds. This differs from mechanical recycling, which only melts and reformulates plastics. The use of microwaves in this chemical process expedites recycling and improves energy efficiency.

Microwave chemical recycling utilises microwave radiation to expedite the decomposition of polymers into viable raw materials. This technique provides a distinct benefit—microwaves can uniformly penetrate materials, facilitating more consistent heating and accelerated reaction times. The integration of a continuous process design facilitates efficient, large-scale plastic recycling.

Comprehending Continuous Process Design:

A continuous process design denotes a manufacturing system in which materials traverse the production line without interruption. In contrast to batch processing, which involves production in stages with intervals, continuous processing guarantees a steady and uninterrupted output.

This means that we can continuously introduce recycling of Waste Plastics, thereby increasing its throughput and efficiency. The continuous process design for microwave chemical recycling enables its operation at industrial scales, making it feasible for extensive waste treatment.

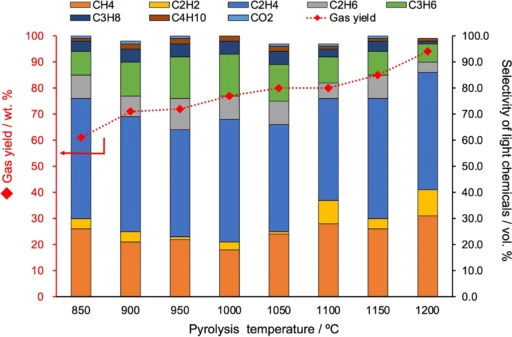

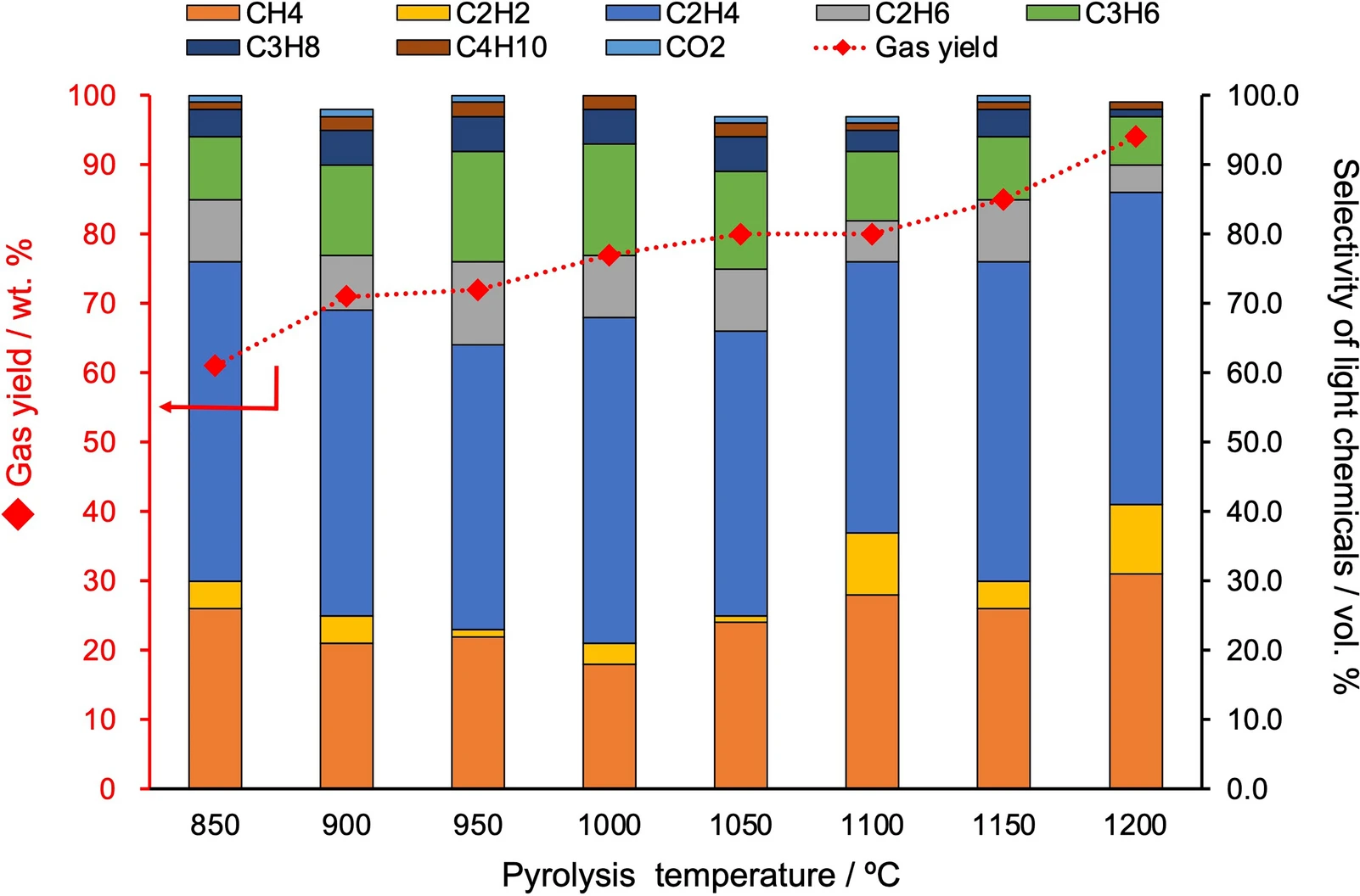

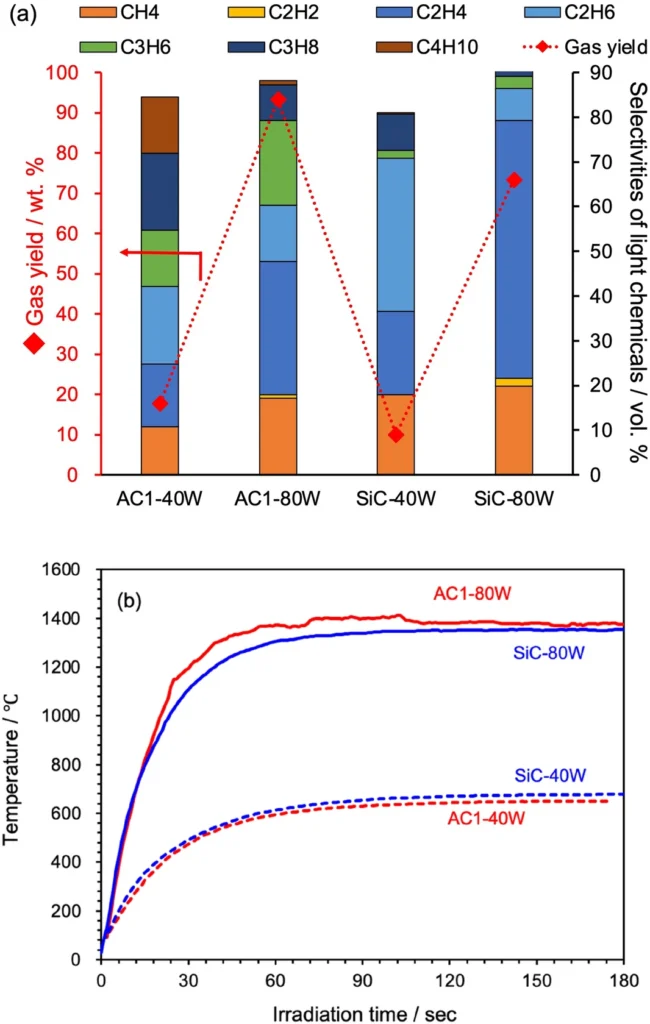

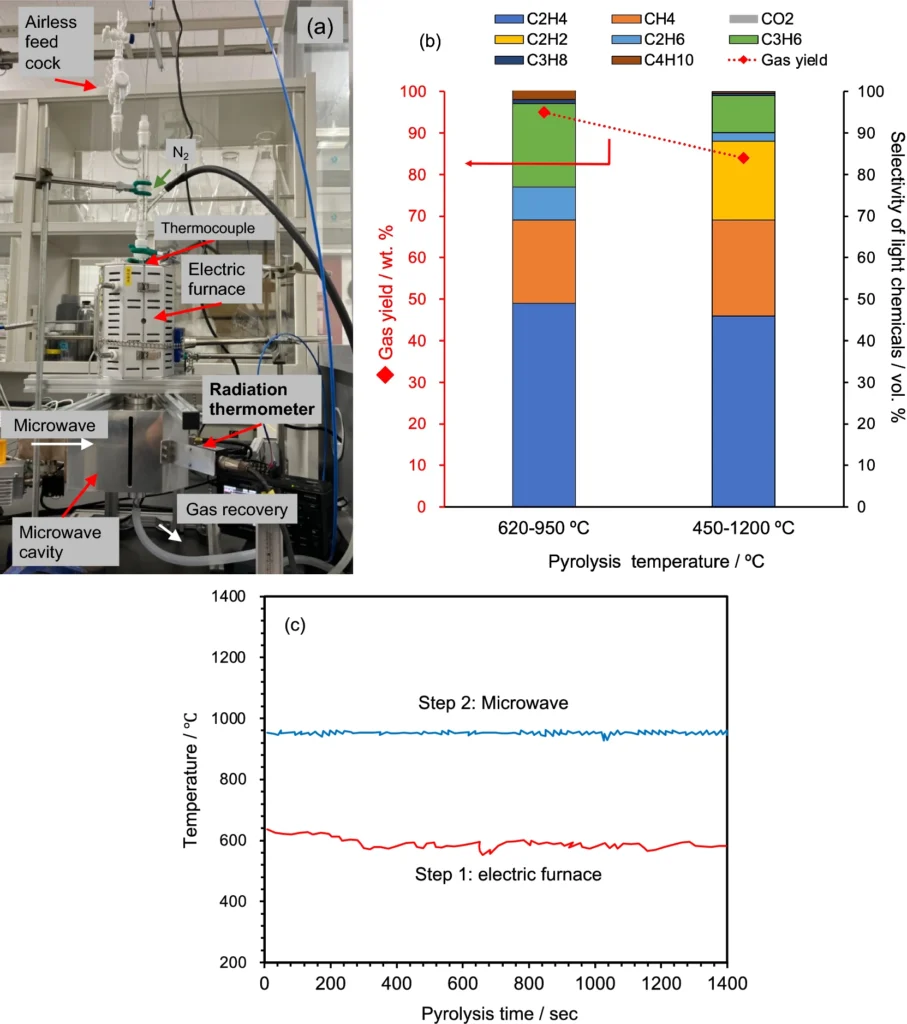

a) Gas yield and composition of products from the chemical recycling pyrolysis of HDPE (0.10 g) using MWs and various MWAHEs (AC1: 0.05 g, SiC: 0.20 g) under fixed MW powers of 40 and 80W. (b) Temperature profiles for each of the conditions.

Advantages of Ongoing Process Design in Recycling of Waste Plastics:

What’s the significance of continuous process design in the Recycling of Waste Plastics? The advantages are manifold:

Enhanced efficiency: Continuous processing can manage greater quantities of garbage in a reduced timeframe.

Scalability: This architecture facilitates the expansion of operations for industrial applications, alleviating pressure on recycling facilities.

Cost-effectiveness: Continuous processes often yield reduced operational expenses due to fewer interruptions and enhanced efficiency.

Obstacles to Recycling of Waste Plastics Using Conventional Techniques:

Conventional Recycling of Waste Plastics techniques, including mechanical recycling, possess considerable constraints. Mechanical recycling entails the melting and reforming of polymers, which may lead to a decline in material quality over time. This limits the frequency of recycling plastic before it loses its functionality.

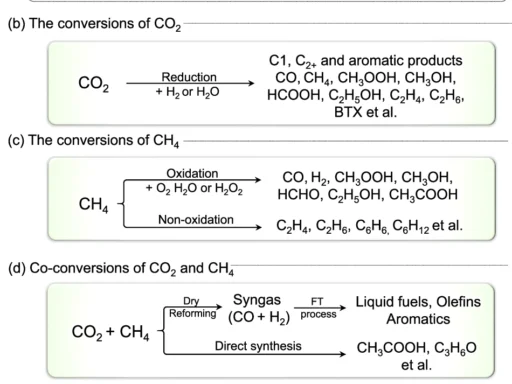

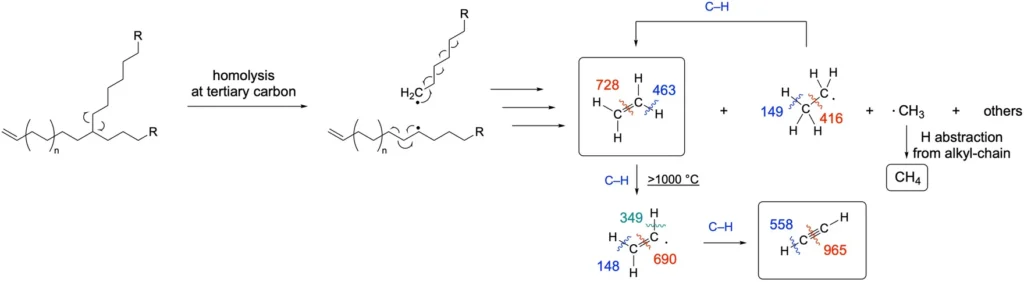

Moreover, mechanical Recycling of Waste Plastics frequently yields low-quality plastics unsuitable for high-value applications. Environmental issues are crucial; numerous conventional procedures necessitate substantial energy consumption, leading to an increased carbon footprint. Proposed mechanism of PE pyrolysis. Values are in kJ mol−1 and represent the energy required to break only the bond indicated.

Function of Microwave-Absorbing Heating Components:

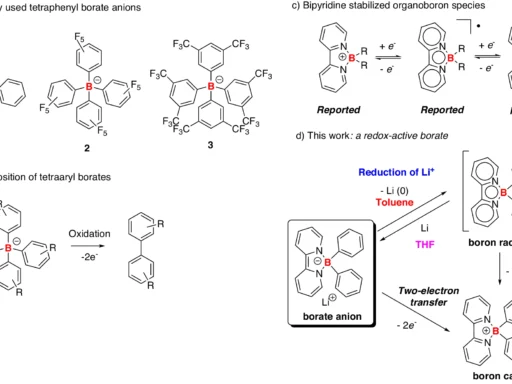

A fundamental aspect of microwave chemical Recycling of Waste Plastics is the incorporation of microwave-absorbing heating devices. These materials are critical because, in isolation, polymers cannot effectively absorb microwave energy. Incorporating minerals such as carbon black or magnetite into the process enables these elements to absorb microwave radiation and transform it into heat, facilitating the chemical decomposition of polymers.

Microwave Heating as a Chemical Recycling of Waste Plastics Mechanism:

Microwaves generate heat through dielectric heating, which stimulates the molecules within a substance. In microwave chemical recycling, the heating devices absorb microwaves and deliver thermal energy to the plastic, resulting in its decomposition into simpler chemical compounds.

This approach is significantly quicker and more energy-efficient than traditional heating methods, as microwaves directly target the substance instead of warming the surrounding surroundings.

Benefits of Employing Microwave Heating in Recycling:

Microwave heating presents numerous significant benefits:

Accelerated reaction times: microwave heating significantly enhances the chemical reactions required for plastic degradation.

Energy efficiency: In contrast to traditional methods, microwave heating minimizes energy wastage by directing energy precisely onto the material.

Minimised environmental impact: Decreased energy consumption results in a smaller carbon footprint, making microwave recycling a more sustainable alternative.

The Continuous Microwave Recycling Method is being developed:

Designing an efficient continuous microwave recycling process necessitates consideration of a number of factors:

Feed system: The process must include a method for continuously introducing waste plastics into the system.

Heating elements: Incorporating microwave-absorbing materials is critical for effective heating.

Reaction chamber: The reaction chamber is where microwaves interact with the polymers and facilitate the chemical reaction.

Output system: We must continuously remove the by-products (monomers or other compounds).

Categories of Plastic Appropriate for Microwave Chemical Recycling:

Not all polymers exhibit uniform responses to microwave chemical recycling. Plastics such as PET (polyethylene terephthalate), HDPE (high-density polyethylene), and PS (polystyrene) are especially appropriate due to their relative ease of decomposition into fundamental chemical constituents.

Nonetheless, certain polymers, such as PVC (polyvinyl chloride), pose more difficulties owing to the emission of toxic substances during degradation.

Essential Parameters in the Microwave Chemical Recycling Process:

Numerous factors influence the effectiveness of microwave chemical recycling.

Temperature control: We must conduct the reaction at an ideal temperature to prevent the degradation of the desired products.

The feed rate and throughput: An optimally designed system must manage the appropriate quantity of plastic to provide a continuous flow.

Reaction time and yield: Optimising the yield of recyclable materials is critical for ensuring the process’s economic viability.

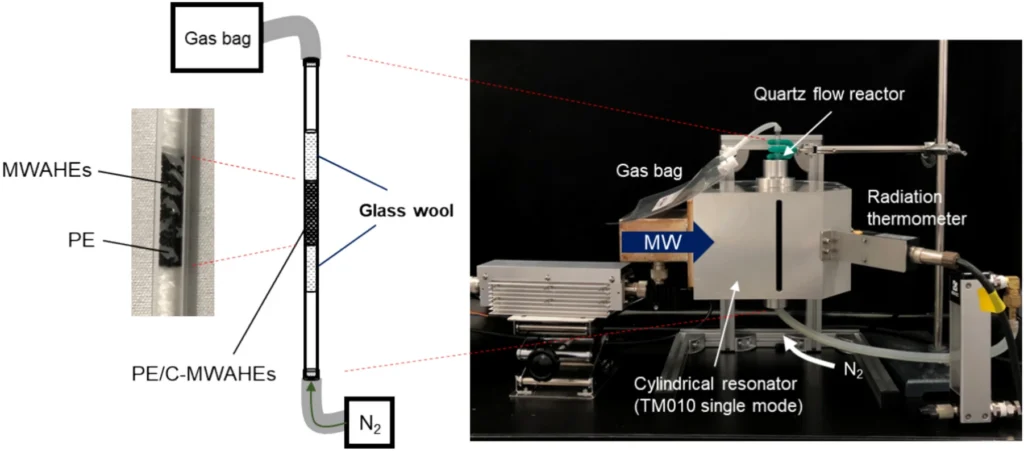

photo credit Schematic of the quartz flow reactor filled with sample materials (left) and the experimental equipment configuration including the MW equipment (right).

Microwave Recycling: Practical Applications

Multiple locations have tested microwave chemical recycling. A pilot project in Europe has illustrated the process’s capacity to recycle PET into high-quality monomers suitable for the manufacture of new plastics. Comparable programs in Asia aim to expand the technology to address the escalating plastic waste issue.

Ecological and financial advantages:

Microwave chemical recycling has the potential to transform plastic waste management. It diminishes the quantity of plastic that accumulates in landfills and oceans while providing a financially feasible method to convert waste into valuable resources. This technology is environmentally and economically superior to existing methods because it uses less energy and produces high-quality recyclable materials.

Prospective Pathways for Microwave-Assisted Chemical Recycling:

With the advancement of this technology, we expect improvements in efficiency, scalability, and material compatibility. Researchers are investigating novel microwave-absorbing materials and refining system designs. Governments and companies must work together to improve solution adoption and address the global plastic waste problem.

Final Analysis:

The ongoing design of continuous microwave chemical recycling presents a viable solution to a major global environmental issue. This approach utilises microwave technology and advanced heating elements to recycle plastics efficiently and responsibly. As we advance and enhance this technology, it may prove pivotal to a more sustainable future.

Frequently Asked Questions:

1). What is microwave-assisted chemical recycling?

Microwave chemical recycling is a method that deconstructs plastics into their fundamental chemical constituents by utilising microwave radiation to accelerate the reaction.

2). What are the differences between microwave heating and traditional heating methods?

Microwave heating directs energy specifically onto the substance, rendering it more rapid and energy-efficient compared to conventional heating, which warms the surrounding environment.

3). Is this procedure applicable to all varieties of plastic for recycling?

Not all plastics are appropriate for microwave chemical recycling. Certain materials, such as PET and HDPE, are effective, whereas others, such as PVC, present difficulties due to detrimental by-products.

4). What are the obstacles to scalability in microwave chemical recycling?

Scaling up necessitates a reliable supply of plastic trash, optimization of microwave absorption, and management of various plastic types.

5). In comparison to conventional methods, what is the energy efficiency of microwave chemical recycling?

Microwave recycling is typically more energy-efficient because it focuses specifically on the material, minimizing energy loss and accelerating reaction times.

For more chemistry blogs, visit chemistry Master