Table of Contents

An overview of Synthesis L-cyclodextrins:

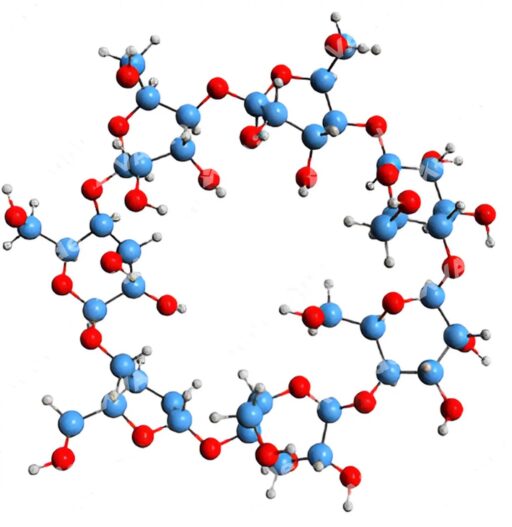

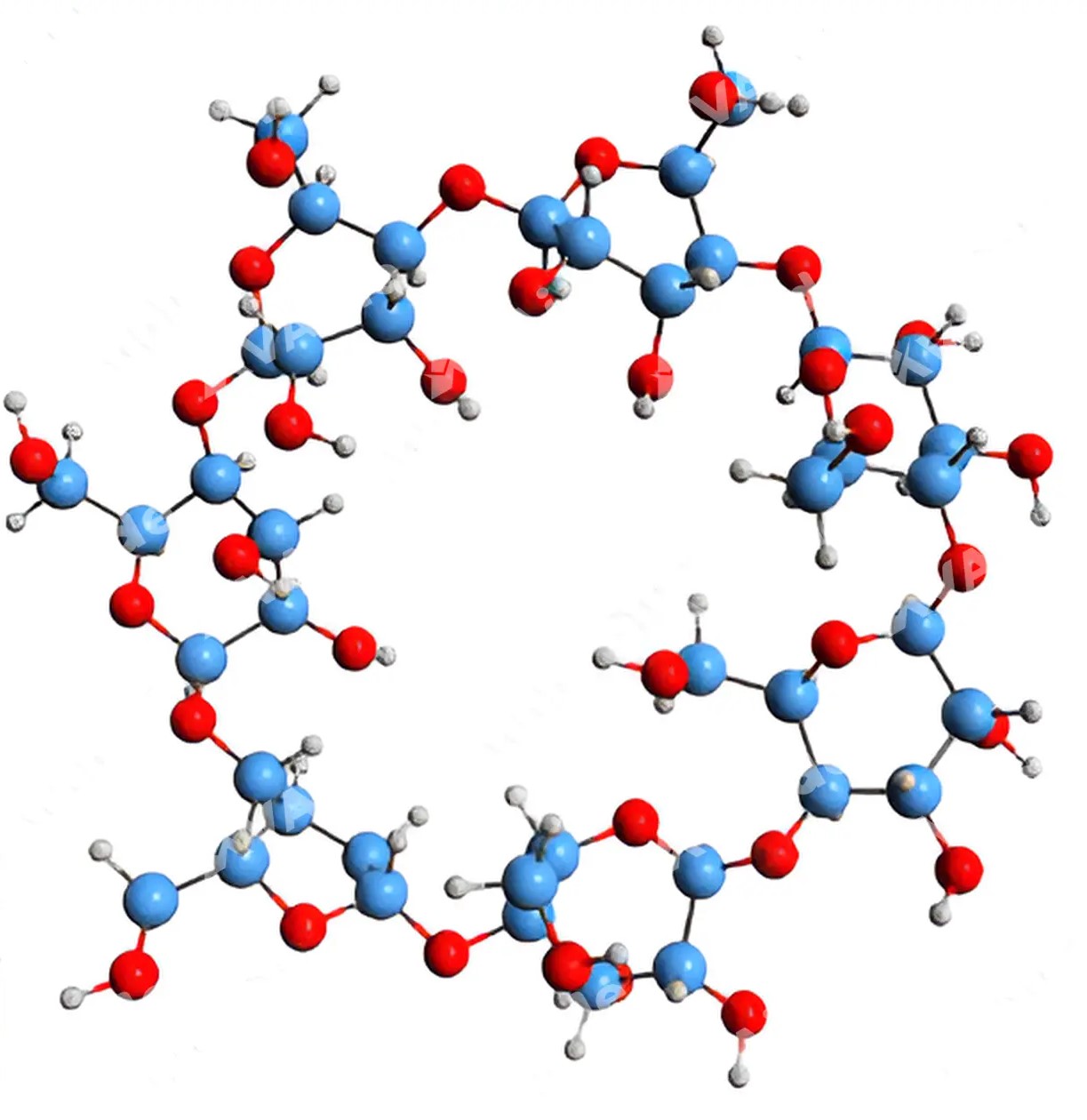

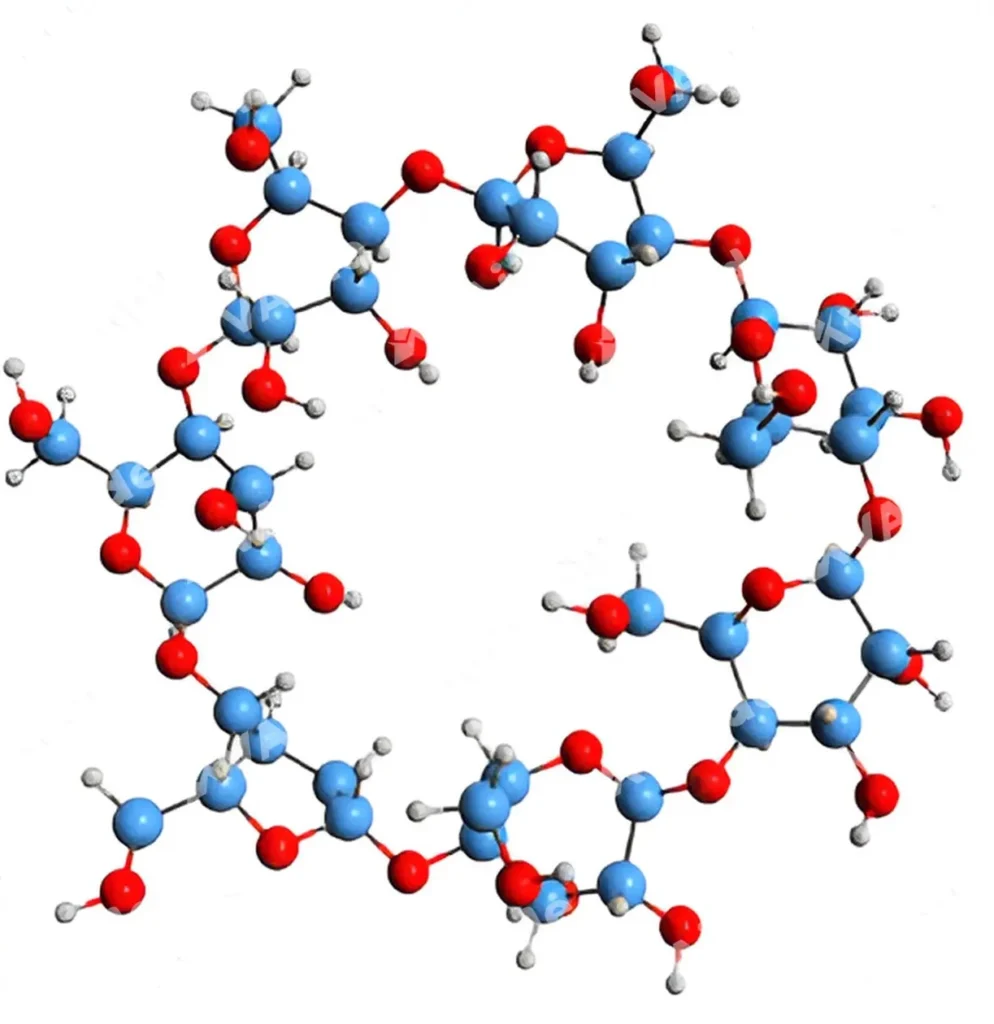

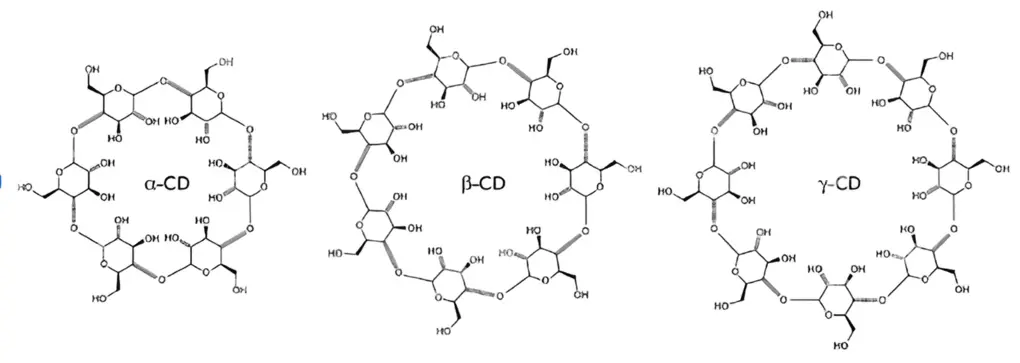

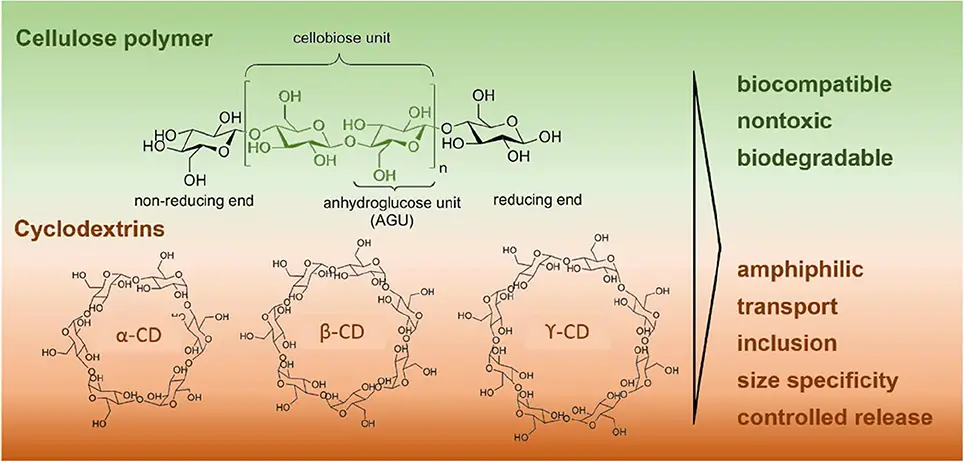

L-cyclodextrins, also called cyclodextrins, are interesting cyclic oligosaccharides made up of glucose units connected by α-1,4-glycosidic bonds. These molecules have a peculiar truncated cone form, with a hollow that repels water and an outer surface that attracts water. Several industries, including pharmaceuticals, food, cosmetics, and agriculture, use these molecules due to their molecular structure.

Synthesis of L-Cyclodextrins:

Synthesis of L-Cyclodextrins refers to the process of combining different elements or components to create something new or more complex.

In the case of L-cyclodextrins, synthesis is the process of making these cyclic oligosaccharides from starting materials that are less complicated. By employing precise synthesis techniques, scientists can manipulate the characteristics of L-cyclodextrins to fulfil precise requirements in the industrial and commercial sectors.

The significance of synthesising L-cyclodextrins:

The synthesis of L-cyclodextrin is highly relevant due to its wide-ranging ramifications in multiple sectors. By customising the synthesis process, it becomes possible to control and modify the properties of L-cyclodextrins, resulting in improved functions and expanded applications. Their ability to adapt and be used in many ways makes them essential in businesses that are looking for innovative solutions in medicine delivery, encapsulation, flavour modulation, and other areas.

Synthesis techniques:

a). Chemical Synthesis of L-Cyclodextrins:

Chemical synthesis of L-Cyclodextrins refers to the process of creating new chemical compounds by combining different chemical elements or molecules.

Chemical synthesis is the primary method for producing L-cyclodextrins. This method entails using particular reagents and reaction conditions to cause the cyclisation of precursor molecules, usually starch or its derivatives. Catalysts can also help to create the intended cyclic structures.

b). Enzymatic Synthesis of L-Cyclodextrins:

Enzymatic synthesis of L-Cyclodextrins refers to the process of creating molecules using enzymes.

Enzymatic synthesis provides a more environmentally friendly and precise option for manufacturing L-cyclodextrins. These are enzymes called cyclodextrin glycosyltransferases (CGTases) that help turn starch or similar substances into L-cyclodextrins by using mild reaction conditions. This approach guarantees a high level of product purity and is suitable for large-scale production.

c). Supramolecular Synthesis of L-Cyclodextrins:

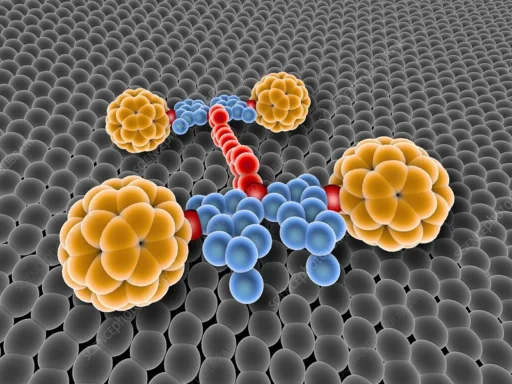

Supramolecular synthesis of L-Cyclodextrins refers to the process of creating complex structures by assembling molecular components through non-covalent interactions.

Supramolecular synthesis utilises non-covalent interactions to arrange molecular building blocks into L-cyclodextrin structures. This approach frequently utilises host-guest chemistry or template-directed assembly to regulate the production of cyclic oligosaccharides. Supramolecular synthesis provides benefits in terms of precise structure formation and adaptable design.

Elaborate illustration of chemical synthesis:

a). Initial components:

The process of creating L-cyclodextrins usually begins by chemically synthesising linear polysaccharides like starch, amylose, or amylopectin. These polysaccharides act as the main components for the next cyclisation process.

b). Experimental parameters:

Precise reaction conditions are required for the chemical synthesis of L-cyclodextrins to promote the cyclisation of the starting components. People often use high temperatures and acidic pH conditions to promote the creation of cyclic oligosaccharides. Catalysts or cyclisation agents can be used to accelerate the reaction kinetics.

c). Device:

The linear polysaccharide undergoes a process known as intramolecular transglycosylation during the chemical manufacture of L-cyclodextrins, leading to the development of cyclic structures. The process entails the breaking of glycosidic linkages and the subsequent formation of new bonds, resulting in the distinctive truncated cone-shaped structure of L-cyclodextrins.

d). The product is formed:

The main outcomes of chemical synthesis are L-cyclodextrins of different dimensions, such as α-, β-, and γ-cyclodextrins. Various parameters, such as reaction circumstances, precursor concentration, and catalyst activity, influence the size distribution of cyclodextrins. Specific cyclodextrin fractions can be isolated for specialised applications through the use of purification procedures.

Uses of artificially produced L-cyclodextrins:

L-cyclodextrins that have been synthesised are extensively utilised in various sectors due to their distinct molecular characteristics and functions. Several noteworthy applications include

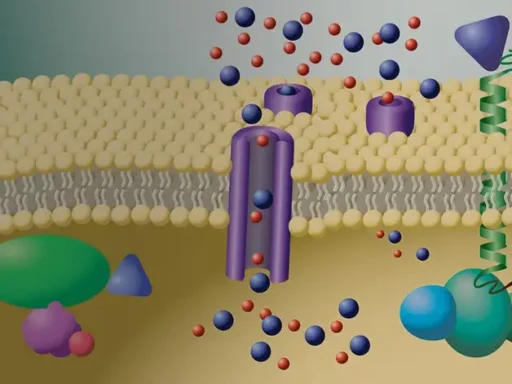

1. L-cyclodextrins are highly adaptable carriers for medicinal molecules, enabling precise release and enhanced absorption of drugs.

2. The hydrophobic cavity of L-cyclodextrins allows for hydrophobic molecules to be encapsulated, protecting against degradation and improving stability.

3. L-cyclodextrins are employed in the food business to encapsulate flavours and smells, offering controlled release and concealing unpleasant tastes.

4. L-cyclodextrins aid in the stabilisation of volatile compounds found in formulations such as fragrances, essential oils, and cosmetic goods. This helps to extend their shelf life and effectiveness.

5. Environmental remediation uses L-cyclodextrins to remove pollutants and toxins from soil, water, and air, thereby supporting sustainable remediation initiatives.

In conclusion:

The production of L-cyclodextrins is a crucial element of contemporary chemistry and materials research, facilitating the creation of novel solutions in diverse industries. Researchers are using various synthesis methods to fully exploit the capabilities of L-cyclodextrins, leading to progress in medicine delivery, food technology, environmental remediation, and other fields.

Frequently Asked Questions:

1. What are L-Cyclodextrins, and How they are synthesized?

L-cyclodextrins are cyclic oligosaccharides that are synthesised by a process known as cyclisation.

L-cyclodextrins are a type of cyclic oligosaccharide that consists of glucose units connected by α-1,4-glycosidic linkages. Chemical, enzymatic, or supramolecular techniques produce them, each with unique benefits and uses.

2. What are the main applications of synthesized L-cyclodextrins?

L-cyclodextrins that have been synthesised are used in several fields, such as medicine delivery, encapsulation of active components, flavour modulation, stabilisation of volatile molecules, and environmental cleanup.

3. How does the chemical synthesis of L-Cyclodextrins occur?

The chemical synthesis of L-cyclodextrins entails the development of these compounds through a series of chemical reactions. During this synthesis process, a variety of factors can influence the formation of the desired product.

Chemical synthesis entails the process of cyclizing linear polysaccharides using precise reaction conditions, resulting in cyclic oligosaccharides. Temperature, pH, and catalyst activity influence the size and distribution of cyclodextrin products.

4. L-cyclodextrins play a significant role in medication delivery systems?

L-cyclodextrins make it easier for medicines to get to the right tissues or organs by helping them dissolve better and release their medicine progressively.

5. What applications do synthesised L-cyclodextrins have in environmental remediation?

Synthesised L-cyclodextrins are used to eliminate pollutants and toxins from environmental matrices like soil, water, and air. Mechanisms such as adsorption and encapsulation achieve this.

For more chemistry blogs, visit chemistry master